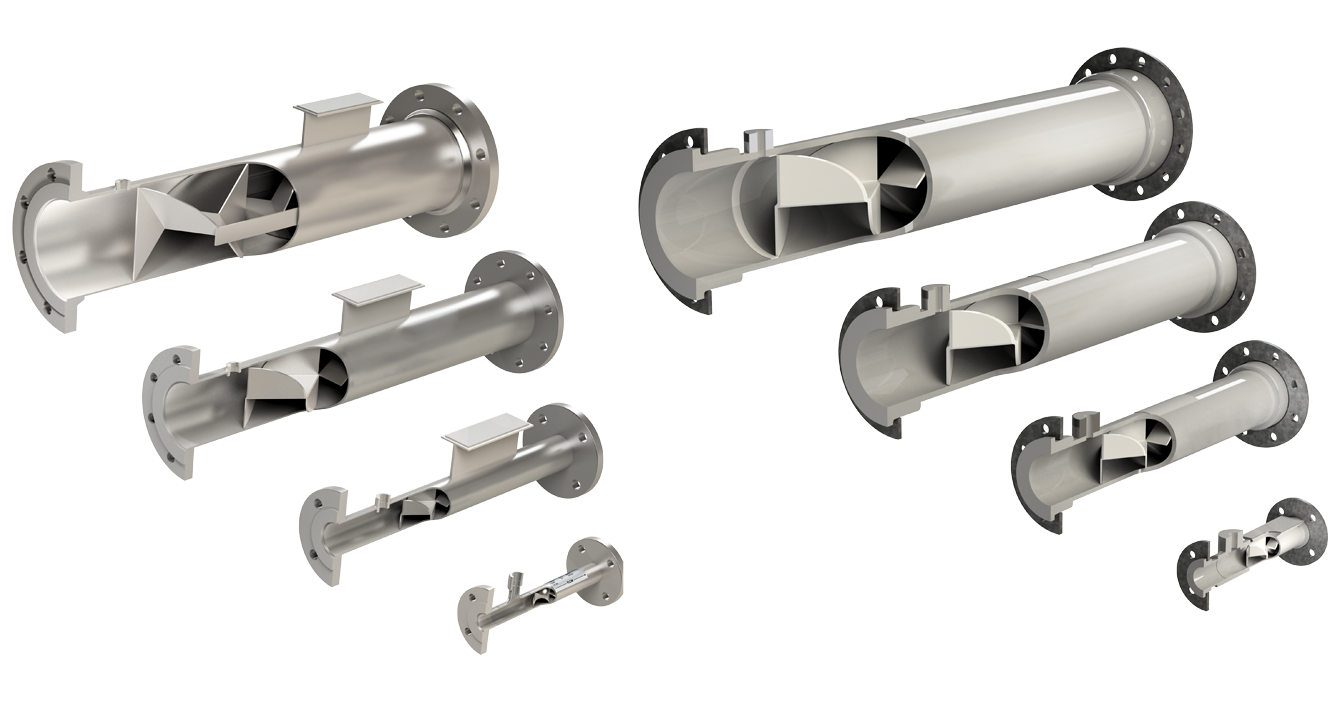

Static mixers are efficient and reliable equipment for mixing liquids, gases or slurries without the use of moving parts. Thanks to their simple design, energy efficiency and minimal maintenance, they have become indispensable in industrial processes. In this article, we'll look at how a static mixer works, what industries it's used in, and what its main advantages are.

How does a static mixer work?

Unlike dynamic mixers, static mixers have no motors or rotating elements. Its operation is based on changing the direction of flow using internal elements such as spirals, blades or inserts that create turbulence. As a result, the components are mixed as the liquid or gas moves through the pipeline, without the need for an additional source of energy.

The main advantages of static mixers

- Energy efficiency. They are powered by flow without an electric drive.

- Low maintenance costs. No wearing parts.

- Compactness. Ideal for installation in confined spaces.

- Easy integration. Easy to integrate into existing piping systems.

- Versatility. Suitable for mixing liquids of various viscosities, gases and two-phase media.

Where are static mixers used?

Static mixers are used in many industries due to their flexibility and reliability:

- Chemical industry: Reagent dosing, emulsification, neutralisation.

- Water treatment: Mixing coagulants, flocculants, and chlorine.

- Food industry: Homogenisation of drinks, sauces and pastes.

- Pharmaceuticals: Sterile dosing of components.

- Oil and gas industry: Mixing reagents in pressurised systems.

How to choose a static mixer?

When selecting a static mixer, parameters such as flow rate, viscosity, chemical aggressiveness of the medium, temperature, pressure, pipework type and required mixing quality should be taken into account. It is recommended that you contact a specialist to help you find the best solution for your process.