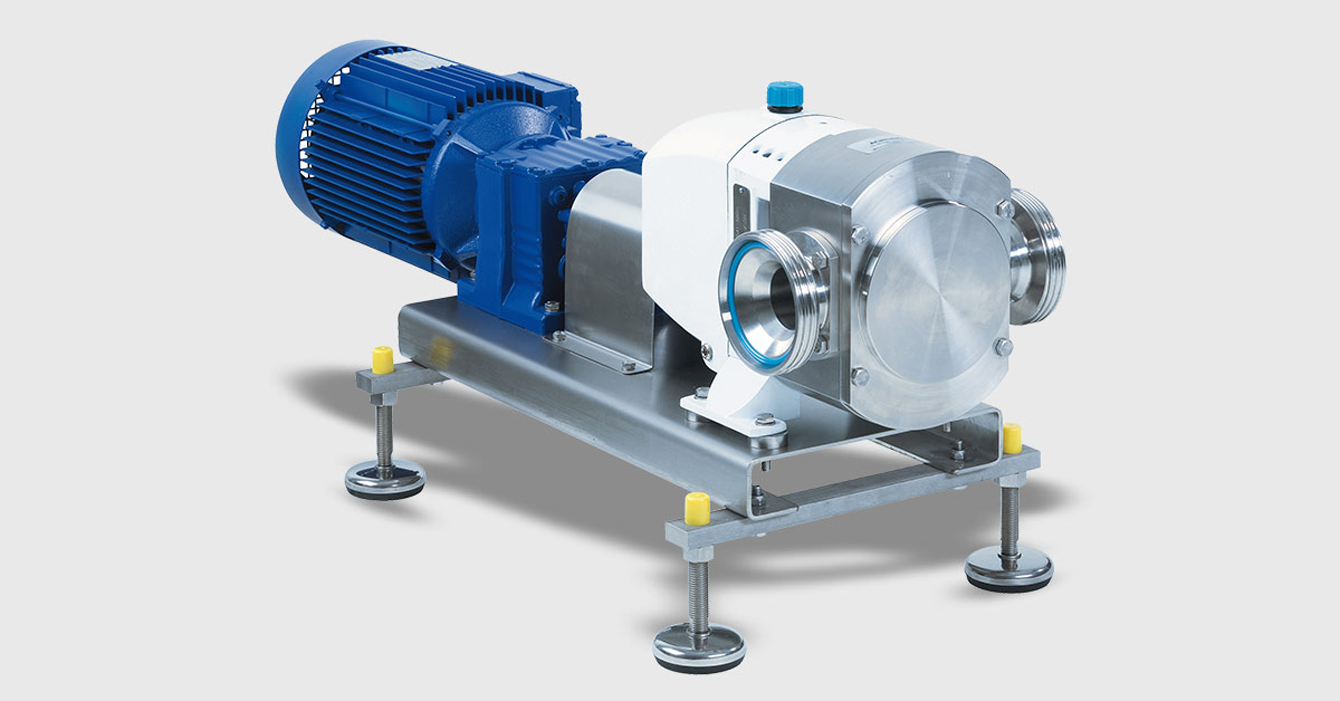

A type of positive displacement pump that transports liquids by the rotation of two synchronized cams (rotors). This principle ensures gentle, pulsation-free fluid transport, making these pumps ideal for handling sensitive, viscous and aggressive media.

Application of cam pumps

- Food industry: They are used for transportation of milk, yogurt, syrups, creams, oils and other food products where delicacy and lack of foaming are important.

- Cosmetics industry: Ideal for thick and viscous products such as creams, gels or shampoos.

- Pharmaceutical industry: Ensure high standards of hygiene when working with sensitive substances.

- Chemical industry: They are used for pumping aggressive chemicals due to the resistance of the materials.

- Paint and varnish industry: Ensure precision and uniformity when working with paints, varnishes and other thick materials.

Features of cam pumps

- Delicate liquid transportation: The absence of contact between moving parts and the product minimizes damage to the liquid structure.

- Capable of handling viscous and thick liquids: They work effectively with creams, sauces, pastes and other similar products.

- High hygiene: Easy to disassemble for sanitization, compliant with FDA and EHEDG standards.

- “Heating shirt": Allows you to maintain a stable liquid temperature during transportation, which is especially important for thick products or substances that crystallize.

- Versatility: They are suitable for use in a variety of environments, from food to chemical industries.

- Safety in explosive environments: Due to the absence of electrical components, the formation of sparks is eliminated.

How to choose a cam pump

- Product characteristics: Consider the viscosity, temperature, chemical composition, and abrasiveness of the medium.

- Productivity: Determine the volume of pumping per unit of time.

- Body and cam material: Ensure that the materials are suitable for the operating conditions.

- “Heating shirt": It is necessary for the stable transportation of temperature-sensitive liquids.

- Hygiene and ease of maintenance: An advantage for areas where compliance with sanitary standards is critical.