Сучасний промисловий автоклав — це високотехнологічне обладнання, від якого безпосередньо залежать безпека продукту, стабільність виробничого процесу та собівартість готової продукції. Саме тому при виборі автоклава для виробництва необхідно оцінювати не лише ціну або продуктивність, а весь комплекс технічних і експлуатаційних параметрів.

Автоклавування залишається найбільш поширеним і надійним методом пастеризації та стерилізації у харчовій промисловості. Проте ефективність цього процесу значною мірою визначається правильністю підбору обладнання.

З чого почати вибір автоклава

Перед тим як розглядати конкретні моделі, важливо чітко визначити технологічні задачі, які має вирішувати автоклав на вашому підприємстві. Помилки на цьому етапі часто призводять до перевитрат енергії, нестабільної якості продукту або обмеження виробничих можливостей у майбутньому.

Ключові параметри для аналізу:

1. Тип і обсяг стерилізації

Необхідно врахувати:

- вид продукції (м’ясні, рибні, овочеві консерви, дитяче харчування, соуси тощо);

- тип упаковки (жерстяна банка, скло, реторт-пакет, пластикові контейнери);

- необхідну продуктивність та кількість циклів на добу.

Ці фактори визначають потрібний об’єм камери автоклава та режим термічної обробки.

2. Технічна інтеграція

Автоклав має відповідати інфраструктурі підприємства:

- параметрам електропостачання;

- системам подачі води та пари;

- вимогам до вентиляції та відведення конденсату.

3. Якість та рівномірність стерилізації

Критично важливо, щоб автоклав забезпечував:

- рівномірний розподіл температури по всій камері;

- мінімальні температурні відхилення між упаковками;

- контроль і реєстрацію параметрів циклу для простежуваності та аудиту.

4. Зручність експлуатації

Сучасні автоклави повинні мати:

- автоматизоване керування;

- інтуїтивно зрозумілий інтерфейс;

- мінімальні вимоги до обслуговування;

- швидкий доступ до вузлів для сервісу.

5. Енергоефективність і експлуатаційні витрати

Низьке споживання пари, води та електроенергії напряму впливає на собівартість продукції, особливо при безперервному виробництві.

6. Надійність та сервісна підтримка

Репутація виробника, наявність сервісної підтримки та запасних частин — обов’язкові критерії для промислового обладнання.

Основні типи промислових автоклавів

Залежно від технологічних вимог, у виробництві застосовуються різні типи автоклавів:

Автоклави з гравітаційним охолодженням

Прості та надійні в конструкції, проте мають триваліший цикл охолодження, що обмежує продуктивність.

Автоклави з примусовою циркуляцією

Використовують насоси для активного охолодження, значно скорочуючи тривалість циклу та підвищуючи ефективність виробництва.

Вакуумні автоклави

Застосовуються для продуктів та матеріалів, що потребують повного видалення повітря з камери перед стерилізацією.

Предвакуумні автоклави

Поєднують вакуумну та циркуляційну технології, забезпечуючи швидку, рівномірну та контрольовану стерилізацію при високих навантаженнях.

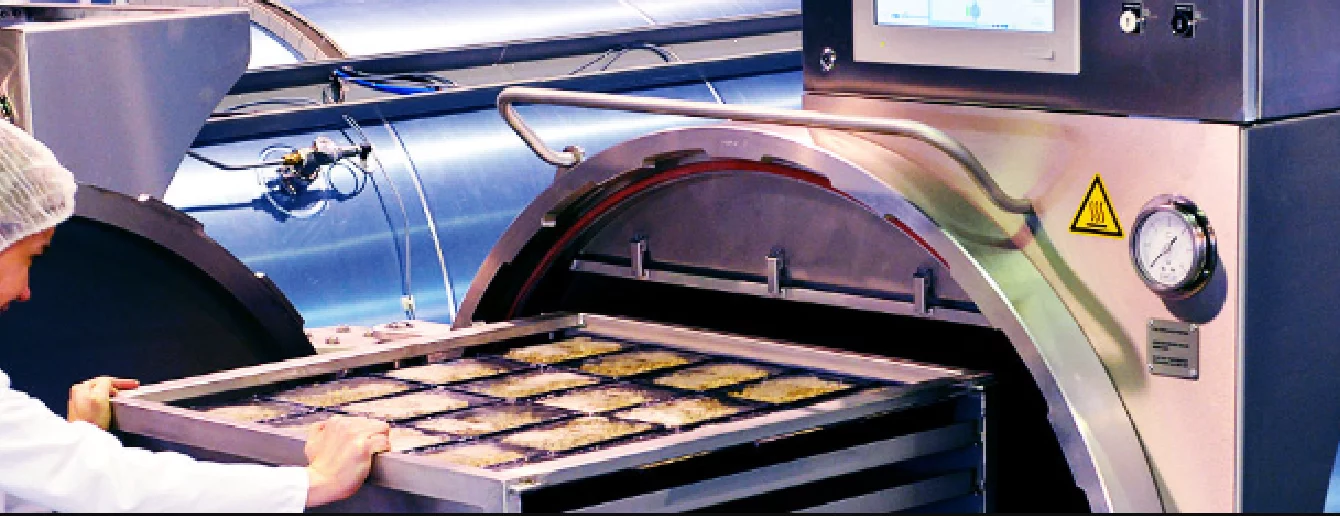

Steriflow — еталон у промисловій стерилізації

Company STERIFLOW (Франція) є світовим лідером у виробництві горизонтальних автоклавів та розробником технології «водний каскад», яка забезпечує:

- надзвичайно рівномірний розподіл температури;

- мінімальні температурні відхилення;

- зниження споживання енергії та води;

- збереження текстури, кольору та поживної цінності продукту.

Автоклави Steriflow широко застосовуються у виробництві консервів, готових страв, соусів, кормів для тварин та інших продуктів, де якість і стабільність процесу мають вирішальне значення.

Інженерна підтримка від Steiner

Company Steiner Ukraine допомагає підібрати автоклав з урахуванням:

- типу продукту та упаковки;

- необхідної продуктивності;

- вимог до стерилізації або пастеризації;

- енергетичних та просторових обмежень підприємства.

Ми супроводжуємо проєкт від підбору обладнання до введення в експлуатацію та сервісного обслуговування.