SAER Elettropompe was founded by Carlo Favella in 1951 as a small workshop producing pumps for agricultural use.

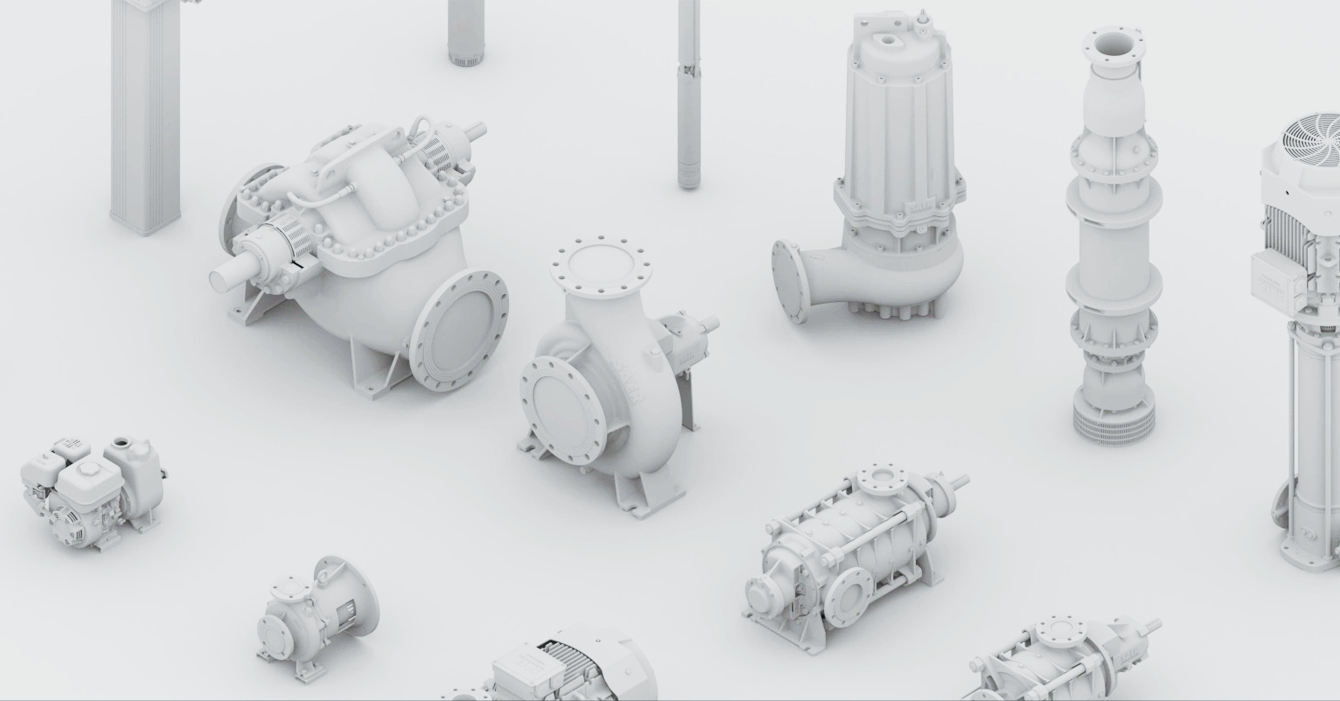

Problems in wastewater treatment: causes and effective solutions

Wastewater treatment is a critical process for industry and municipal systems. A significant portion of facilities operate with outdated equipment, leading to regular repairs, excessive energy costs, and the risk of non-compliance with regulations.

Homogenisation and the quality of dairy products: Why it matters to consumers

In this article, we will take a detailed look at how homogenization affects dairy products, why it is important for consumers, and how modern equipment, such as Steiner's Indug homogenizers, ensures high quality of the final product.

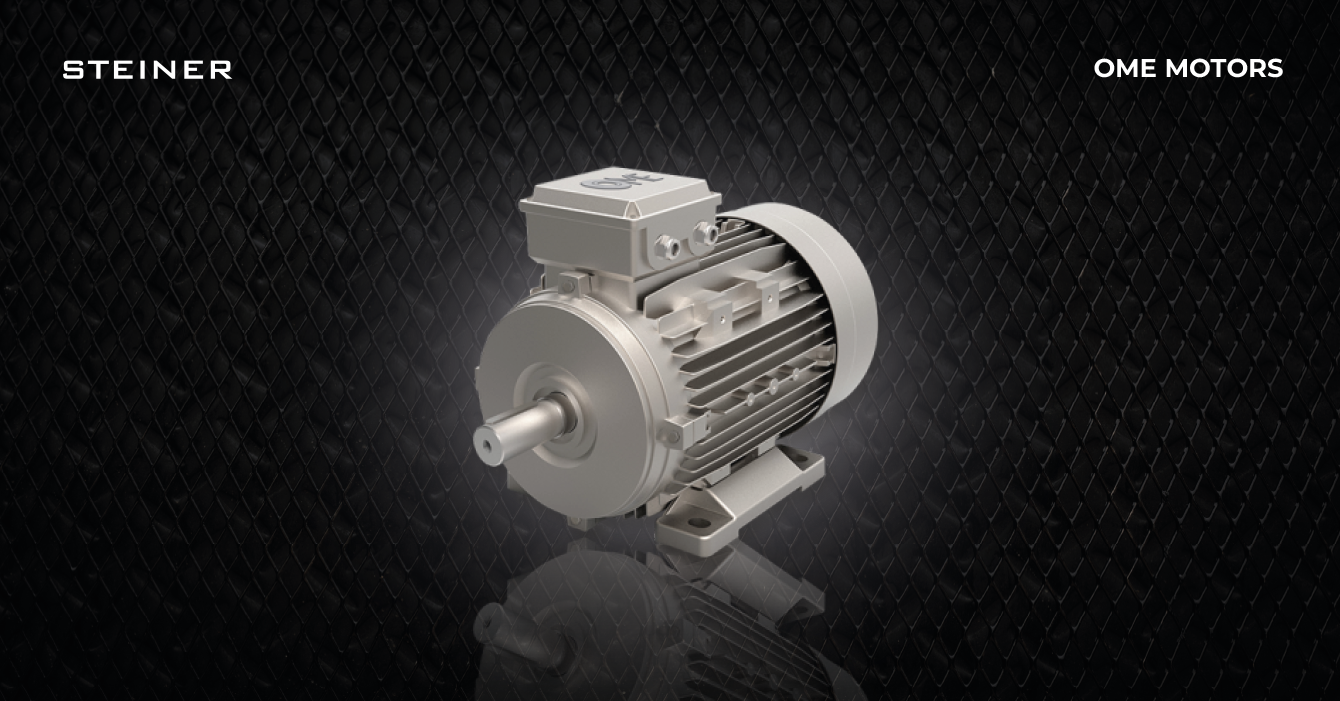

OME Motors — industrial electric motors of European quality. Official partner in Ukraine — Steiner

OME Motors is an Italian company headquartered in Brescia that has specialized in the design and manufacture of industrial electric motors for over 50 years.

What is the difference between seals for pumps that work with aggressive liquids?

Seals are one of the key elements of pumping equipment, especially when it comes to pumping aggressive media, affecting system stability and overall process safety.

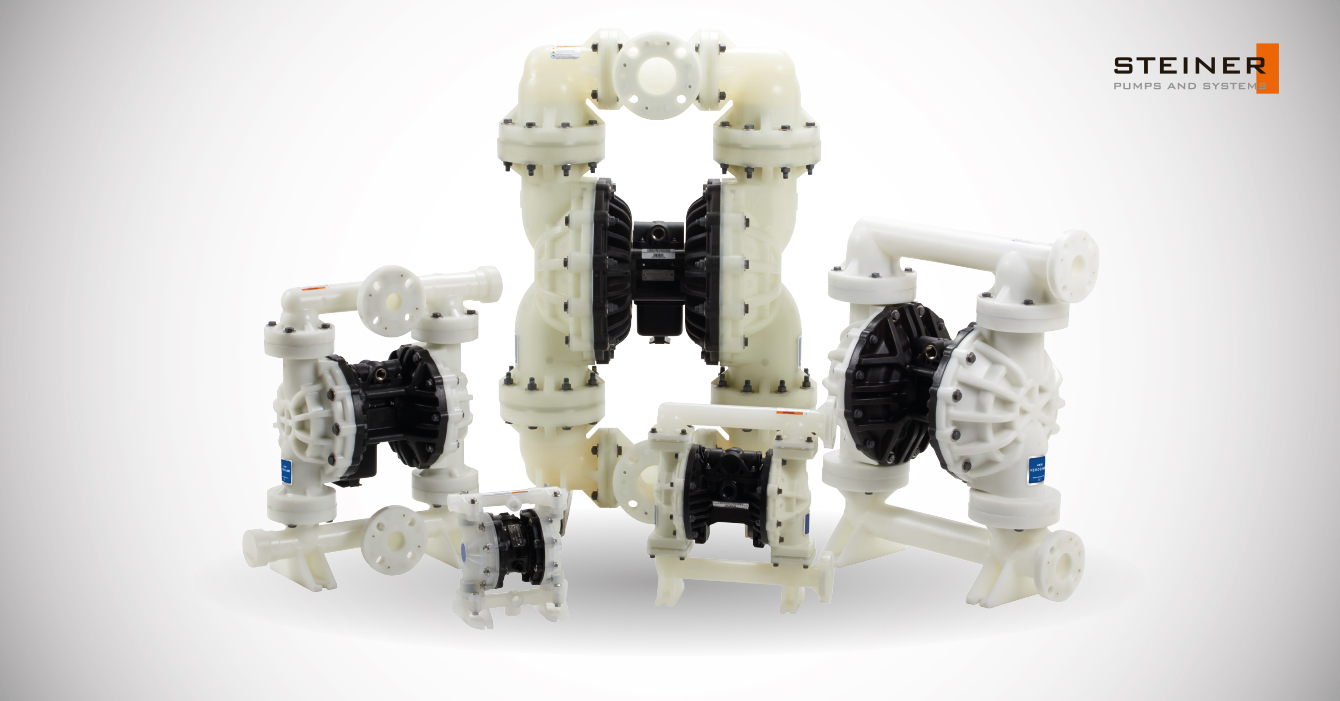

Diaphragm pumps: industrial applications and Steiner expertise

Diaphragm pumps, also known as membrane pumps, are indispensable equipment in many industries due to their versatility, reliability and ability to handle aggressive, viscous or abrasive media.

Three screw pumps: The reliable solution for stable pumping of viscous liquids

In industry, three-screw pumps are used to pump lubricants, fuel oil, diesel fuel, polymer mixtures, technical oils and other liquids that require careful and stable delivery.

Pumping equipment for the food industry - requirements and hygiene standards

Pumps are an important component of technological processes in the food industry, ensuring the safe and efficient transportation of various products.

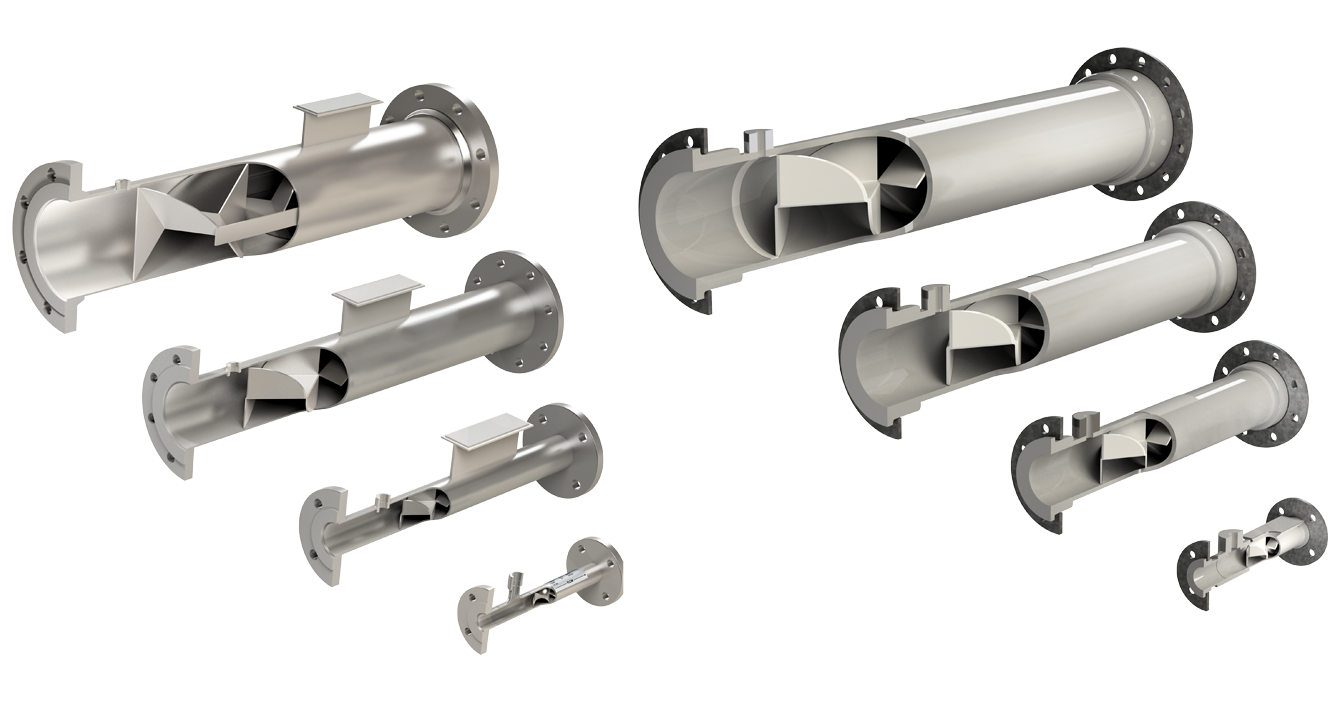

Static mixers: how they work, their advantages and applications

Static mixers are efficient and reliable equipment for mixing liquids, gases or suspensions without the use of moving parts.

In-Line Pumps: energy-efficient in-line pumping

Thanks to their compact design with vertical or horizontal pipe connections, circulation pumps ensure a stable flow of water, technical fluids or waste water with minimal pressure loss.