How to choose the right pump for your production - tips from Steiner experts

For modern production, the right choice of pumping equipment is extremely important. After all, it determines the efficiency of the enterprise, the overall quality of the final product and the stability of all technological stages.

Premium pet food market: how health claims affect pricing

The global pet food industry is experiencing impressive growth as owners increasingly view their pets as full-fledged members of the family.

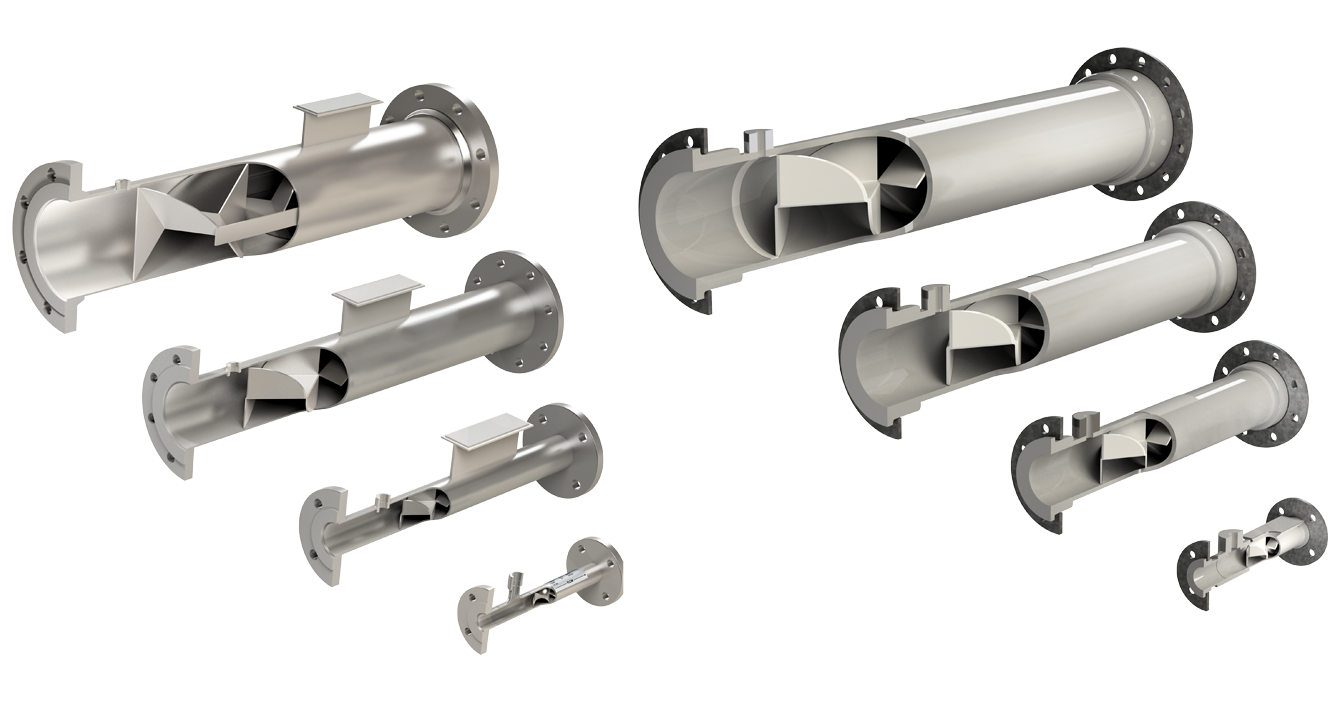

Static mixers: how they work, their advantages and applications

Static mixers are efficient and reliable equipment for mixing liquids, gases or suspensions without the use of moving parts.

Steiner and Bank Credit Dnipro: Easy Financing for Your Business

Steiner has joined forces with Bank Credit Dnipro to open up new business development opportunities for our customers. Now you can quickly and conveniently obtain financing for equipment that will take your production to the next level.

In-Line Pumps: energy-efficient in-line pumping

Thanks to their compact design with vertical or horizontal pipe connections, circulation pumps ensure a stable flow of water, technical fluids or waste water with minimal pressure loss.

Taras Repetovskyi in Dairy Technologies magazine: Steiner Ukraine's innovative solutions for ice cream production

In the March issue of Dairy Technologies, the company's commercial director, Taras Repetovsky, shared insights into modern ice cream production.

Screw pumps: principle of operation, features and applications

Screw pumps belong to the positive displacement type of pumps. Their operation is based on a rotating screw (rotor) that moves inside a stator with a special profile.

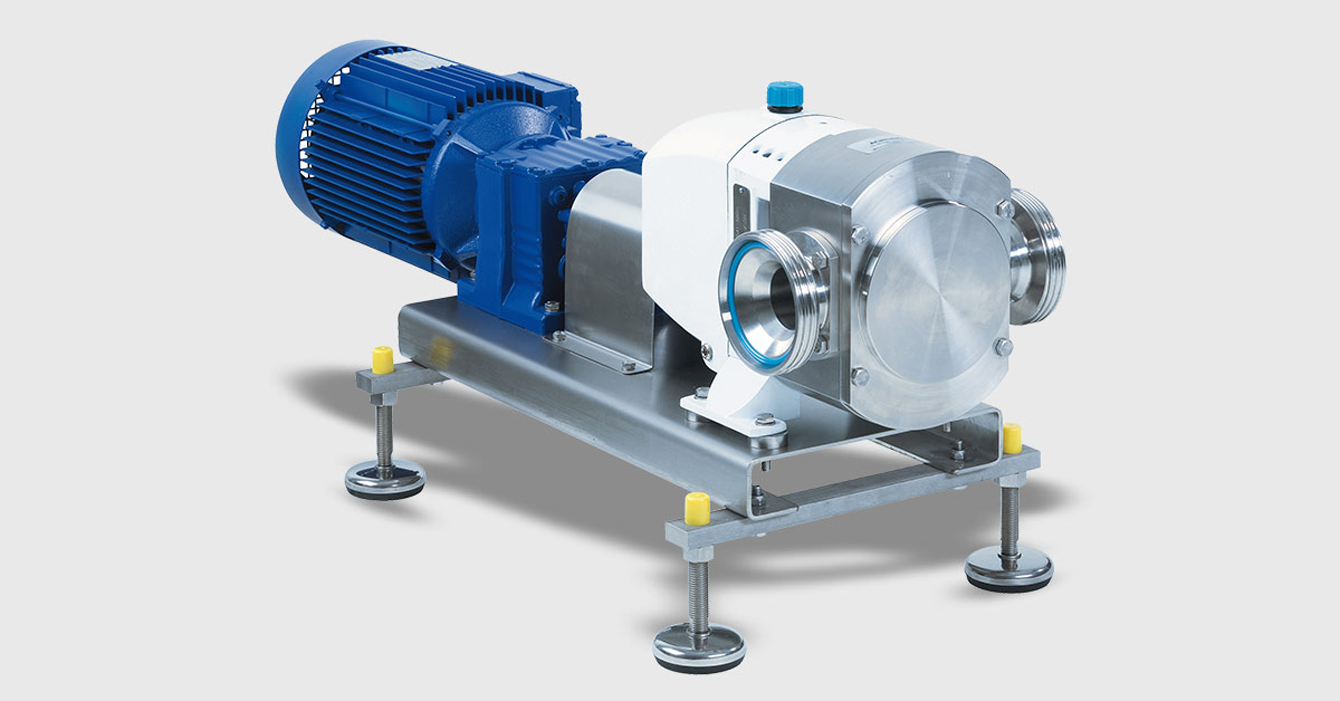

Cam pumps: Delicate and efficient pumping of liquids

This principle ensures smooth, pulsation-free fluid transport, making these pumps ideal for handling sensitive, viscous and aggressive media.

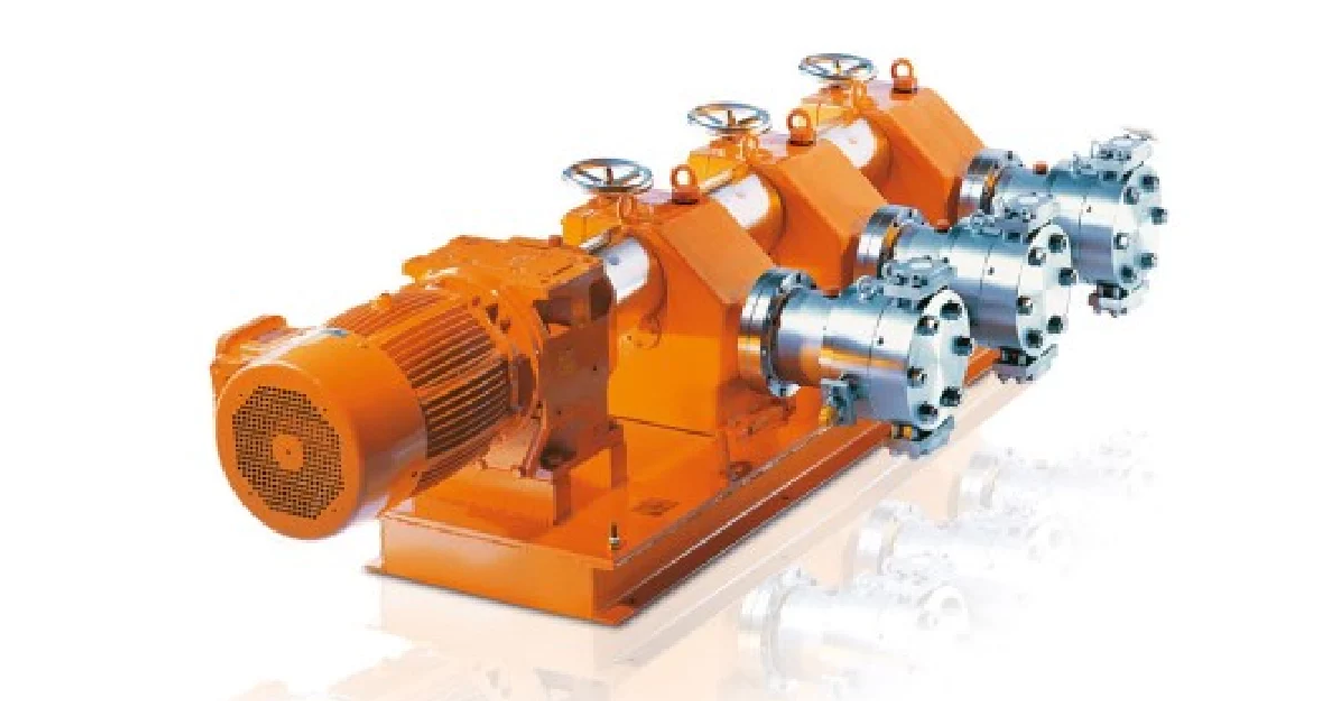

Twin-screw pumps: principle of operation, advantages and selection of the optimal model

The basis of the twin screw pump is two screws that rotate in opposite directions inside a sealed housing. The fluid is captured by the screws, forming sealed chambers, and is transported without shear or pulsation.

Diaphragm pumps: a universal solution for various industries

Diaphragm pumps are widely used in food production due to their ability to pump liquids of varying viscosity while maintaining their structure and properties.