Most manufacturing companies are looking for ways to reduce costs. One such method is to reduce production costs by using lighter weight PET bottles and aluminium cans. But how can you reduce the weight of PET containers without deforming the bottle and losing rigidity? This is what we will discuss in this article.

What is nitrogen? It is a colourless and odourless mineral used in the food and beverage industry to displace oxygen and increase shelf life. Both gaseous and liquid nitrogen are used for this purpose. But few people know that the use of liquid nitrogen also creates overpressure in the bottle and reduces its weight.

Due to its ability to evaporate at room temperature, a drop of liquid increases its volume by a factor of 700 when it becomes a gas. Specific figures can be obtained on an individual basis by experimentation.

There are many factors to consider before implementing a liquid nitrogen system in a food or beverage production line. Insulated equipment is required for storing, transporting or dispensing liquid nitrogen, as it evaporates quickly when exposed to room temperature.

Comparison of tanks and pipelines

Storage tanks are usually available in two types: large bulk storage tanks and small portable tanks called Dewar vessels. Bulk tanks use a double-walled construction that creates a vacuum between the walls. This vacuum jacket is an effective insulation that allows the outer surface of the container to be at room temperature but retain liquid nitrogen inside for long periods of time. Although the insulation is not perfect, heat leakage is inevitable in any type of container. Most tank manufacturers report losses of 0.5 to 2.0% per day.

Large capacity tanks require a piping system from the tank to the point of use, but Dewar vessels only require a short section of pipe because they are usually located close to the point of use.

There are two types of liquid nitrogen pipework: with and without a vacuum jacket. Lines with a vacuum jacket are more efficient and operate without icing. Vacuum jacketed pipework can be either rigid or flexible. Rigid pipes need to be accurately calculated for proper installation in the facility, while flexible hoses are easier to install and allow for more versatile routing.

In turn, jacketless lines are usually insulated with foam, have a heat loss of 20 times more, and also have a larger outer diameter compared to a jacketed pipeline. Foam insulated pipes lose their properties over time as the foam deteriorates. There are a number of criteria to consider when choosing a liquid nitrogen system:

- Personnel safety.

- Reliable operation of the system.

- Reasonable purchase and operating costs.

Each manufacturer has different priorities, but safety must come first. It is important to remember that liquid nitrogen becomes a gas at room temperature and expands up to 700 times its volume. To prevent overpressure or equipment rupture, a proper piping system and protection of the dosing equipment, including safety valves, must be used.

Operating procedures must also be followed, as there is a risk of contamination of the equipment by moisture - the greatest enemy of all cold surfaces. It only takes a small amount of moisture to completely freeze equipment from the inside. It is also important to maintain the right pressure in the bottle. After all, a water bottle with too low a pressure can collapse during stacking or incorrect labelling, and one with too high a pressure can burst during storage.

There are many factors to consider when choosing a liquid nitrogen dosing unit. The initial cost is only a small part of the puzzle. Most production facilities considering liquid nitrogen require proper information and training.

Vacuum Barrier Corporation - is a manufacturer of liquid nitrogen dispensers and related cryogenic equipment. The company has many years of experience in dosing liquid nitrogen into food products: beverages, juices, wine, snacks, oil and still water.

Why Vacuum Barrier?

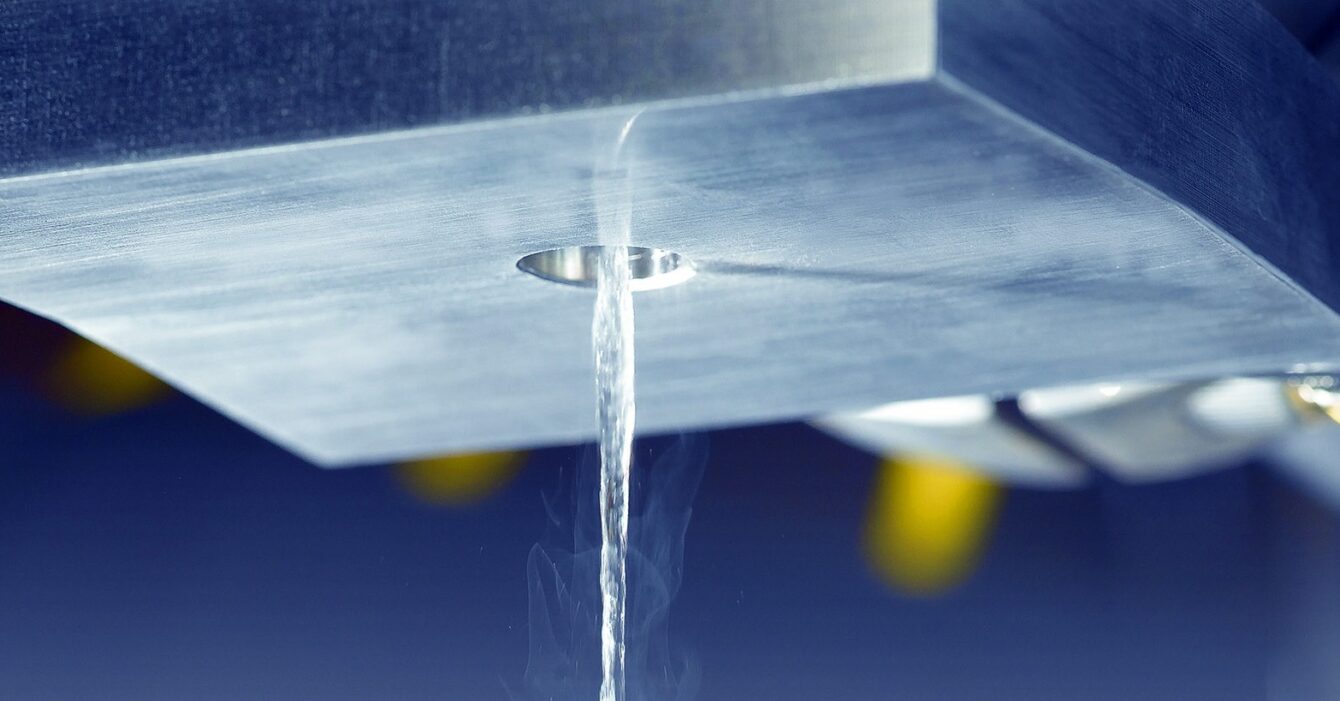

- First and foremost, Vacuum Barrier Systems (VBS) pipettes are hygienically designed.

- There are no technological excesses that make the machine heavier.

- The dosing unit is fully protected from moisture during cleaning, the use of cables is minimal and they are also waterproof.

- Easy integration into an existing line and simple control system.

- The dispenser is powered by two sensors, so there is no need to implement a synchronisation machine in the filling controller.

- Simple, user-friendly Simens control panel with touch screen. Dosing accuracy +/-3.0%.

- With the latest development of the VacuumBarrier, an accuracy of +/-1.0% can be achieved.

- Inaccurate dosing can lead to unstable bottle pressure and subsequently to bottle deformation, leakage, and even destruction of the pallet with the product.

- Depending on the model, VBS dispensers can maintain a supply line pressure of up to 7 bar, which is important for some filling machines.

- Vacuum Barrier pipettes have a self-generating nitrogen gas supply system. There is no need to supply it separately during the pipetting process.

Steiner-Ukraine is the exclusive partner of VacuumBarrier in Ukraine and offers to carry out testing on your product to determine the feasibility of using liquid nitrogen for your specific product and bottle geometry. If the test results are positive, we will be happy to deliver and integrate the dosing unit into your existing turnkey filling machine, as well as provide training for your staff.

Our after-sales service department and service engineer are at your disposal 24/7. a reliable partner for many years to come!