Пластинчасті теплообмінники – це незамінне обладнання на будь-якому виробництві. Адже охолодження – і нагрівання робочих середовищ є основними чинниками перебігу технологічного процесу. І що таке пластинчастий теплообмінник? Давайте детальніше.

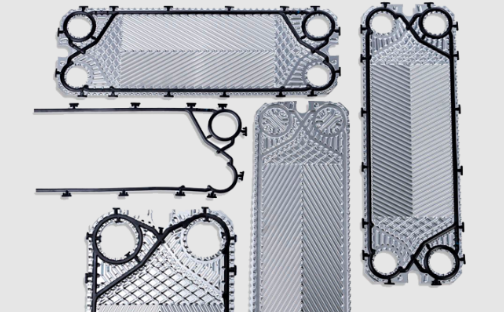

Пластинчастий теплообмінник це спеціальне обладнання, яке призначене для охолодження або нагрівання робочого середовища шляхом передачі теплоти від гарячого теплоносія до холодного через гофровані пластини (нержавіюча сталь, титан, графіт та інші матеріали), які з’єднані між собою. Пластини зібрані таким чином, що гаряче та холодне середовище не змішуються між собою, а рухаються по різні боки пластини. Набір пластин та їх кількість залежить від особливостей процесу та робочих середовищ, які беруть у ньому участь.

How it works

Перший сучасний теплообмінник був зібраний засновником компанії APV (Річард Селігман) у 1923 році, але за іншими наявними даними «батьком» сучасного теплообмінника є Густав де Лаваль, який у 1938 році випустив першу установку для пастеризації.

Пластина теплообмінника є основним елементом конструкції. Їх виробляють методом холодного штампування зі сплавів, стійких до корозії. При цьому витримуючи товщину 0,4 – 1,0 мм. На пластині є 4 отвори, 2 з яких призначені для підведення холодного та гарячого середовища, інші 2 ущільнені додатково контурними прокладками, щоб не дати середовищам змішатися між собою (для цього також передбачені спеціальні дренажні пази). Так як рух у каналах відбувається не по прямій, то потік робочого середовища рухається турбулентно. Додамо сюди ж протитік двох середовищ (гарячої і холодної ) – отримуємо збільшений температурний напір, який у свою чергу інтенсифікує процес теплообміну. Це також позитивно відображається на поверхні пластин – зменшується шар накипу.

Для чого потрібні теплообмінники

Теплообмінники необхідні для виконання таких функцій:

- використання залишкового тепла в результаті застосування електричної енергії;

- контролю хімічних процесів, необхідних для дотримання нормального температурного режиму.

Нові моделі прості і безпечні у використанні. У харчовій індустрії потрібні для пастеризації, а в металургії виступають в ролі охолоджувачів. У суднобудуванні необхідні для підтримки функціонування системи охолодження двигуна. У нафтовій галузі – для крекінгу.

Типи теплообмінників

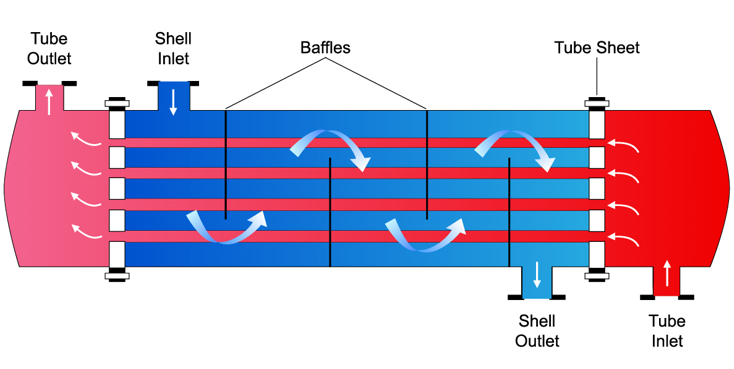

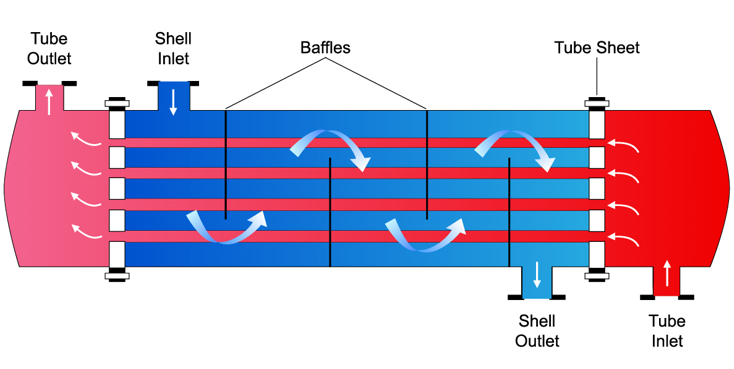

- Кожухотрубний

Advantages:

- Високий тиск

- Екстремальна різниця температур

- Надвисока продуктивність

Недоліки:

- Габарити

- Складність обслуговування

- Складність очистки

2. Двотрубний теплообмінник

3. Паяний теплообмінник

4. Конденсатори/Випарники

5. Конденсатори

Цікаво знати

Якщо існує велика різниця у витраті середовищ або різниця кінцевих температур мінімальна, то можливий варіант багаторазового теплообміну. Це досягається шляхом направлення потоків по «петлі». Такі теплообмінники оснащуються додатково патрубками для підведення робочих середовищ, при цьому середовища вздовж пластин-перегородок рухаються в однаковому напрямку.

Кількість гофрованих пластин та їх вигляд залежать безпосередньо від робочого середовища та технологічного процесу. Це відноситься і до матеріалу пластин: вони можуть бути виготовлені як зі звичайної нж сталі, так і з особливих сплавів, які можуть використовуватися для роботи з дуже агресивними рідинами. Матеріал ущільнень залежить від цих параметрів і підбирається відповідно до фізико-хімічних і технологічних особливостей процесу.

- Робочий тиск (максимальний): 1,6 МПа

- Робоча температура (максимальна): 160 oC (200 oC)

- Поверхня теплообміну (максимальна): 1500 м2

- Пластини: нж сталь AISI316, титан та др

- Ущільнення: каучуки різних марок (EPDM, VITON, NBR )

- Рами: нержавіючі сталі AISI304 і AISI316, вуглецева сталь і др

- Патрубки: нж сталь AISI304 і AISI316, титан та ін

Процес підбору теплообмінника досить кропіткий і трудомісткий процес, адже матеріали повинні бути підібрані правильно, інакше теплообмінне обладнання вийде з ладу або буде працювати неправильно, адже для багатьох технологічних процесів різниця в кілька градусів порушує повністю весь процес і не дає можливості отримати продукт із заданими параметрами.

Наші фахівці допоможуть Вам у підборі і дадуть відповідь на будь-які питання, які Вас цікавлять.

тел.: +38 (044) 390 73 38

e-mail: info@steiner.com.ua