Homogenisation is a key technological process in the dairy industry that significantly affects the quality of dairy products such as milk, cream, yoghurt, cheese and ice cream. For the end consumer, homogenisation means not only a more pleasant taste and texture, but also improved nutritional value and extended shelf life. In this article, we will take a detailed look at how homogenisation affects dairy products, why it is important for consumers, and how modern equipment, such as Indug homogenisers from Steiner, ensures high quality of the final product. We will also touch on issues of service and spare parts supply for homogenisers such as Indug and GEA, which are important for dairy companies.

What is homogenisation and how does it work?

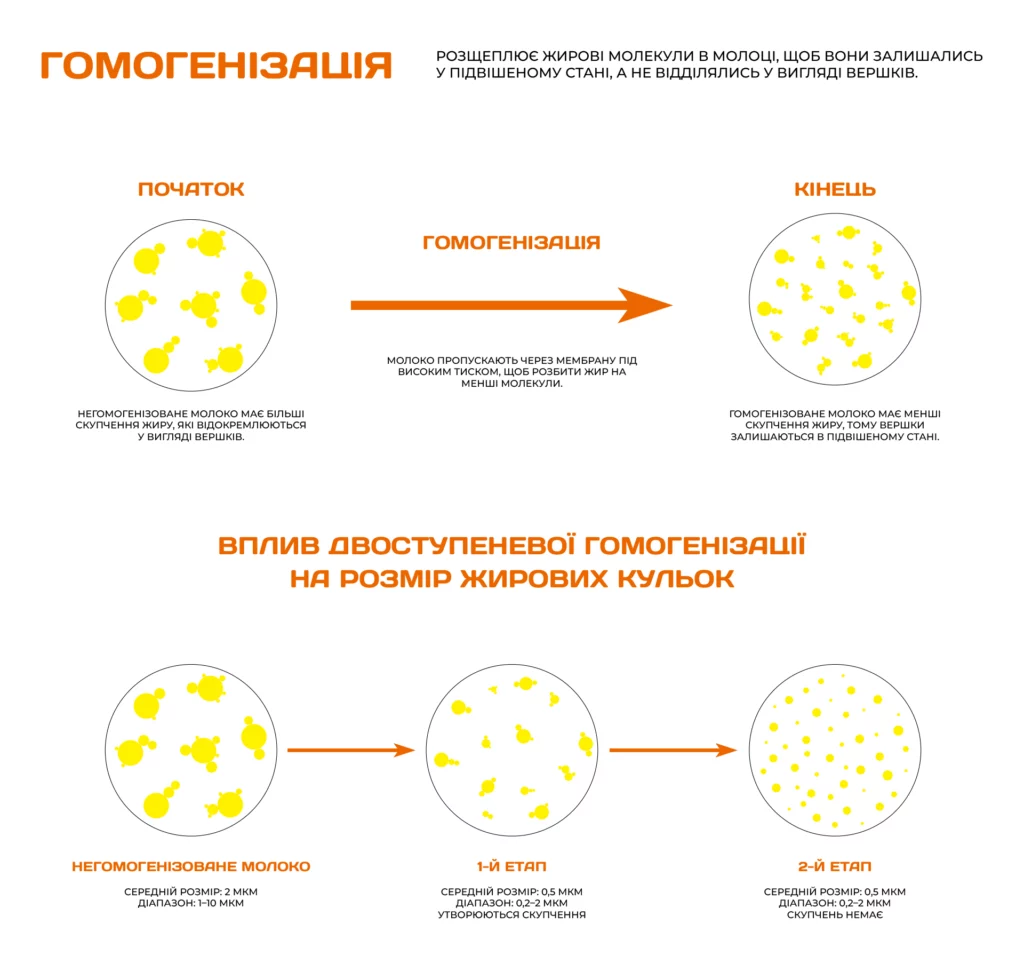

Homogenisation is the process of mechanically breaking down fat globules in milk or other dairy products to microscopic sizes (usually 0.2–2 microns), ensuring their uniform distribution in the liquid. This is achieved by passing the product through a narrow gap in a homogenising valve under high pressure (100–250 bar for milk, up to 400 bar for thicker products). As a result, the milk fat does not settle on the surface, and the product acquires a uniform consistency.

How does this work in practice? For example, in non-homogenised milk, fat rises to the top over time, forming a cream layer. After homogenisation, milk becomes stable, without separation, which makes it more attractive to consumers. According to research conducted in the dairy industry, homogenised milk remains stable for 10–14 days longer than non-homogenised milk when stored correctly (at a temperature of 4–6°C).

The effect of homogenisation on the taste of dairy products

Taste is one of the key factors influencing consumer choice. Homogenisation makes dairy products richer and more pleasant to the taste thanks to the even distribution of fat. For example:

- Milk: Homogenised milk has a smoother, creamier taste compared to non-homogenised milk, where fat can give the product an uneven, sometimes oily aftertaste. Studies show that 78% of consumers prefer homogenised milk because of its consistent taste and lack of fat sediment.

- Yoghurts: Homogenisation ensures a smooth, creamy texture, making yoghurt more pleasant to consume. For example, in fruit yoghurts, homogenisation promotes the even distribution of fruit additives, enhancing the taste experience.

- Cheese: Homogenised cheeses, such as processed cheeses, have a velvety texture, making them ideal for sandwiches or sauces. This is achieved thanks to the stable structure of milk fat after homogenisation.

Homogenisation also allows for a reduction in the amount of flavour additives, as the natural flavour of the product becomes more pronounced. This is particularly important for consumers who prefer natural products with minimal preservatives or flavourings.

Texture: Why homogenisation makes products more enjoyable

The texture of dairy products plays just as important a role as taste. Homogenisation ensures smoothness and uniformity, which is critical to the consumer experience. Here are a few examples:

- Milk and cream: Homogenised milk does not form a cream layer, making it convenient for everyday use. After homogenisation, cream has a delicate, velvety consistency, ideal for coffee or desserts. For example, cream with a fat content of 20% after homogenisation has better whippability, making it popular among confectioners.

- Ice cream: Homogenisation prevents the formation of ice crystals, ensuring a smooth texture for ice cream. According to manufacturers, homogenised milk mixture for ice cream reduces the size of fat globules to 1–2 microns, making the product smoother and creamier.

- Fermented milk products: After homogenisation, yoghurts, kefir and sour cream have a uniform, thick consistency without lumps, which improves their organoleptic properties. For example, sour cream with a fat content of 15–20% after homogenisation is ideal for sauces and dressings, as it does not separate when mixed with other ingredients.

Consumers often associate smooth texture with high product quality, making homogenisation an important factor in creating a positive impression.

Also read: “Homogenizer: Working Principle, Types, and Applications”

Nutritional properties and digestibility

Homogenisation not only improves taste and texture, but also affects the nutritional value of dairy products. By reducing the size of fat globules, milk and other products become easier for the body to digest. Here's how it works:

- Better fat absorption: Smaller fat globules are more easily broken down by enzymes in the stomach, which improves the absorption of fat-soluble vitamins (A, D, E, K). Studies show that homogenised milk is absorbed 10–15% better than non-homogenised milk, which is especially important for children and people with sensitive digestion.

- Preservation of nutrients: Homogenisation does not affect the protein, carbohydrate or mineral content of milk, but it helps to maintain their stability during storage. For example, homogenised milk retains up to 95% of vitamin D after 14 days of storage, whereas in non-homogenised milk this figure may decrease due to separation.

- Fermented milk products: In kefir and yoghurt, homogenisation promotes the even distribution of lactic acid bacteria, which increases their probiotic value. This makes the products more beneficial for the intestinal microflora, as confirmed by studies that indicate 91% digestibility of fermented milk products compared to 32% for regular milk.

For consumers, this means that homogenised products are not only tastier but also healthier, especially for those looking for products with high nutritional value.

Why is homogenisation important for consumers?

For the end consumer, homogenisation means:

- Quality and stability: Homogenised products do not separate, which ensures their attractive appearance and ease of use. For example, in 2023, 85% of shoppers in Europe said they preferred homogenised milk because of its stability and the fact that it did not need to be shaken before consumption.

- Extended shelf life: Homogenisation reduces fat oxidation, allowing milk and cream to stay fresh longer. This is especially important for families who buy groceries for the week ahead.

- Aesthetics and convenience: The smooth texture and absence of sediment make the products more pleasant to consume, especially in beverages such as coffee or cocktails.

- Improved nutritional value: Homogenised products are easier to digest, making them ideal for children, the elderly and those who are health conscious.

The role of equipment in ensuring homogenisation quality

The quality of homogenisation depends directly on the equipment used in dairy plants. Steiner offers high-quality Indug homogenisers that meet the most stringent standards of the dairy industry. These devices provide stable pressure and precise crushing of fat globules, ensuring product homogeneity. For example, Indug homogenisers can operate at pressures of up to 400 bar, which is ideal for processing both low-viscosity milk and thick cream or yoghurt.

In addition, Steiner provides maintenance services for homogenisers, which is critical for the smooth operation of the equipment. Regular maintenance (every 6–12 months) and the use of original spare parts for Indug and GEA homogenisers extend the service life of the devices and reduce repair costs. For example, replacing worn valves or plungers can reduce maintenance costs by 15–20% thanks to the use of high-quality components from leading manufacturers.

Practical examples and case studies

- Milk for coffee: In coffee shops, homogenised milk with a fat content of 2.5–3.2% is the standard for making cappuccino or latte, as it provides the perfect foam and creamy texture. Non-homogenised milk can leave a fatty residue that spoils the taste of the drink.

- Yoghurts for children: Baby food brands use homogenisation to create yoghurts with a smooth texture, making them easier for children to consume. For example, homogenised yoghurts with fruit additives are up to 30% more popular among parents due to their consistency and pleasant taste.

- Premium ice cream: Leading ice cream manufacturers, such as those working with GEA, use homogenisers to create products with a smooth texture, which increases their competitiveness in the market.

FAQ: Frequently asked questions about homogenisation

- Does homogenised milk lose its nutrients?

No, homogenisation does not affect the protein, carbohydrate or mineral content. It only improves fat digestibility and extends shelf life. - Is homogenisation safe for health?

Yes, homogenisation is a safe mechanical process that does not involve the use of chemical additives. Some studies indicate a slight increase in fat oxidation, but this has no significant impact on health. - How do homogenisers affect product quality?

High-quality homogenisers, such as Indug, ensure stable texture and extended shelf life, making products more attractive to consumers. - Where can I find spare parts for homogenisers?

Steiner offers spare parts for Indug and GEA homogenisers, ensuring the durability and reliability of the equipment. For detailed information, please contact Steiner managers. - How often do homogenisers need to be serviced?

Regular servicing (every 6–12 months) and replacement of worn parts, such as valves or plungers, ensure trouble-free operation of the equipment.

Conclusion

Homogenisation plays a crucial role in creating high-quality dairy products that meet the expectations of modern consumers. It improves the taste, texture and nutritional value of milk, cream, yoghurt and ice cream, making them convenient and enjoyable to consume. Thanks to modern homogenisers such as Indug, dairy companies can achieve high quality standards, while Indug and GEA's service and spare parts availability ensure uninterrupted operation of the equipment. If you want to create products that consumers love, homogenisation is your key to success.