Homogenizer — equipment is designed to grind, evenly distribute and mix particles in liquid and semi-solid media. The main purpose of using homogenisers is to obtain a stable and homogeneous mixture that does not delaminate over time. Homogenisation is based on creating high pressure and passing the liquid through a narrow gap between valves or plungers. In the process, the particles are destroyed or evenly distributed in the medium.

- High pressure:

The liquid is pumped in under high pressure (up to 1500 bar). - Cavitation and shear forces:

The fluid flow passes through the homogenising unit, where a combination of forces acts: pressure, cavitation, shear and impact loads. - Grinding of particles:

The particles are broken down to micro- or nano-size to form a homogeneous mixture. - Even distribution:

The resulting mixture remains stable and does not tend to delaminate.

Areas of application

- Food industry:

- Homogenisation of milk, cream, yoghurt, sauces, juices, purees.

- Creating stable emulsions such as mayonnaise or ice cream.

- Pharmaceuticals:

- Preparation of dosage forms: syrups, suspensions, emulsions, vaccines.

- Ensuring an even distribution of active ingredients in the preparation.

- Cosmetics industry:

- Production of creams, lotions and shampoos.

- Formation of emulsions with a fine texture.

- Chemical industry:

- Dispersion of pigments, paints, adhesives, varnishes.

- Working with polymer solutions and suspensions.

- Biotechnology:

- Dissection of cells and isolation of intracellular components (e.g. proteins or enzymes).

Types of homogenisers

- High-pressure homogenisers:

They are used for handling large volumes of product and high pressures.- Areas of application: dairy industry, pharmaceuticals.

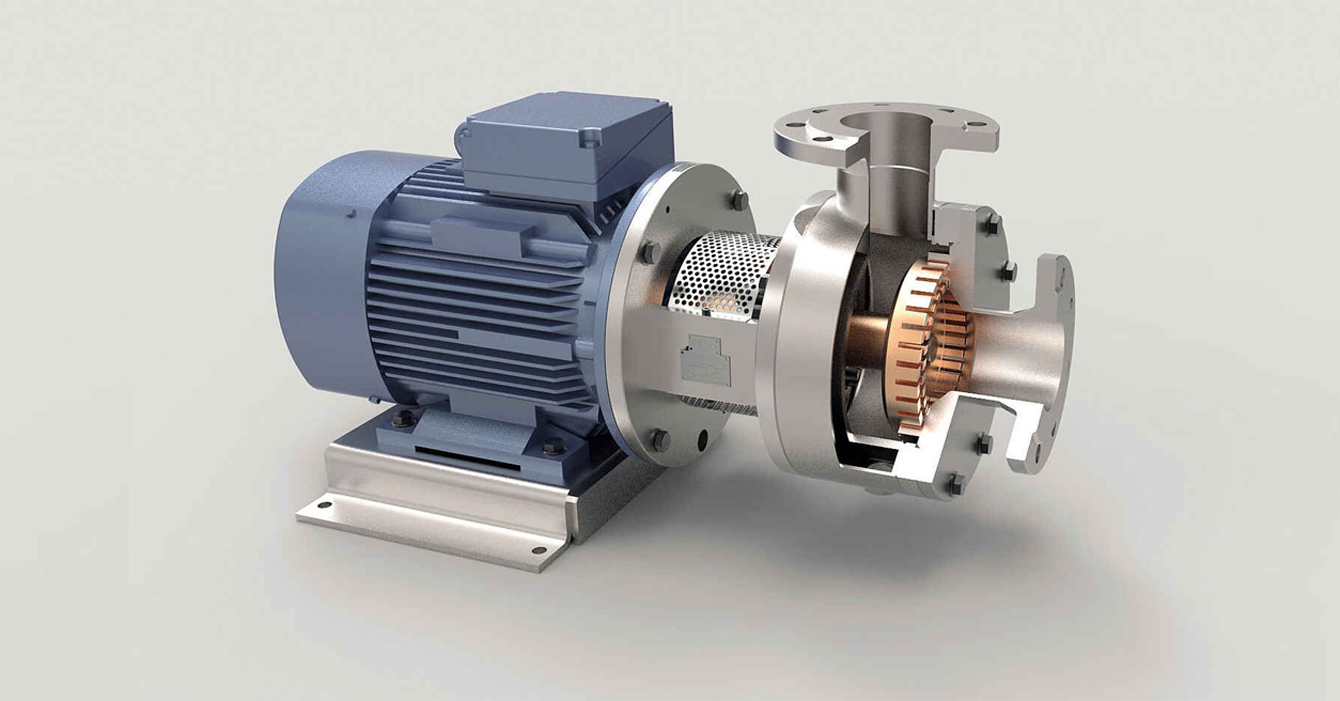

- Rotary-stator homogenisers:

The mixing process is driven by the interaction of the rotor and stator, which generate high shear forces.- Areas of application: cosmetics, chemical processes.

- Ultrasonic homogenisers:

They operate on the principle of cavitation created by ultrasonic waves.- Areas of application: biotechnology, laboratory research.

Features of homogenisers

- Grinding to nanoscale:

The ability to reduce particles to 0.1 micron in size to ensure a consistent product texture. - Uniformity:

Ensure uniformity even in complex multi-component systems. - Compatible with various liquids:

They work with low- and high-viscosity media. - Hygienic:

Most models are made of stainless steel that meets hygiene standards (FDA, EHEDG). - Automation:

Possibility of integration into automated production lines. - Energy efficiency:

Modern homogenisers consume less energy thanks to advanced designs.

How to choose the right homogenizer?

- Product type:

Determine whether an emulsion, dispersion or homogenisation is required. - Pressure level:

Choose equipment that can provide the necessary pressure to achieve the desired particle size. - Productivity:

Consider the volume of product to be processed per unit of time. - Compatible with liquids:

Select a model that matches the fluid characteristics (viscosity, temperature, chemical composition). - Materials:

For aggressive or sterile environments, choose models made of AISI 316L stainless steel. - Additional features:

- Compatible with CIP/SIP systems.

- Availability of automatic settings and monitoring systems.