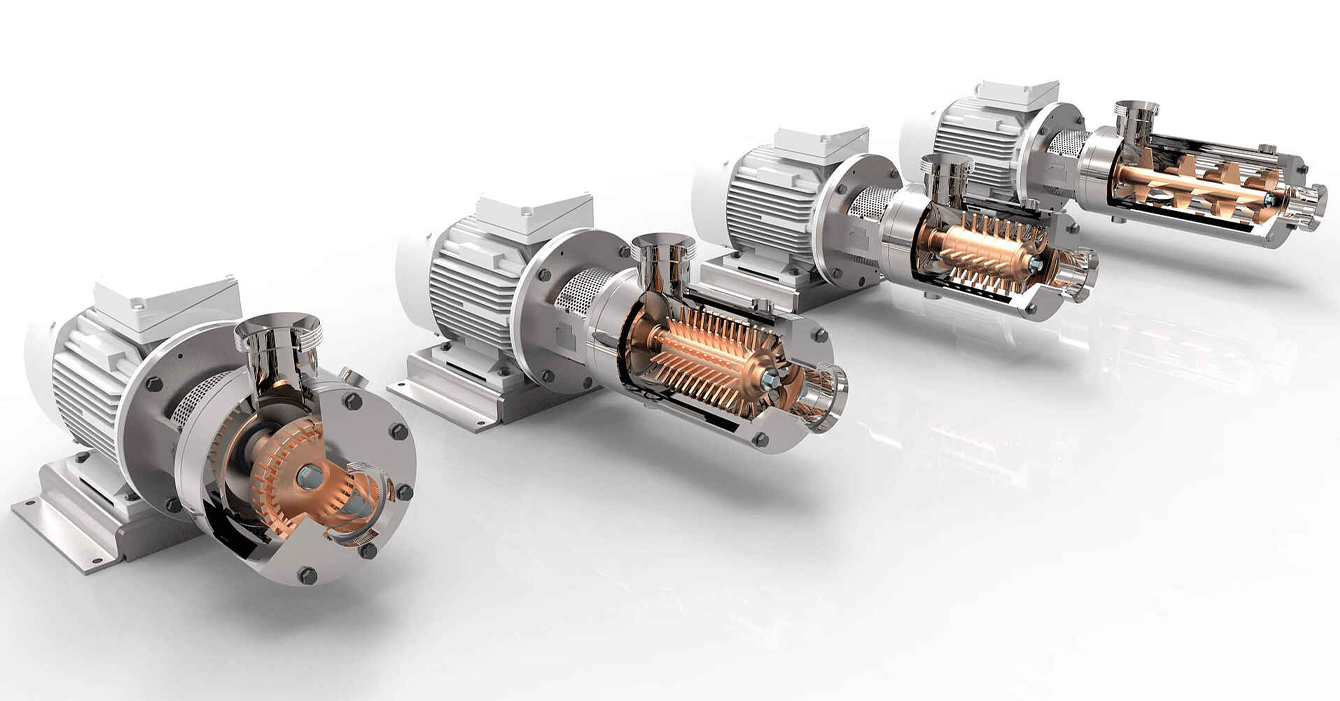

Dynamic mixer — are high-tech equipment for intensive mixing, emulsifying, dispersing or homogenising liquid and semi-solid products. Due to the use of high-speed rotors and static components, dynamic mixers ensure uniformity and high quality of the final product. The dynamic mixer is based on the interaction between a rotating rotor and a stationary stator. As the rotor rotates, the liquid or mixture passes through the gaps between the rotor and stator, where it is subjected to intense mechanical stress:

- Mixing: The fluid components are mixed.

- Dispersion: Solid particles are crushed to a microscopic size.

- Emulsification: A stable emulsion is formed from two liquids that do not normally mix (e.g. water and oil).

- Homogenisation: It ensures an even distribution of particles in the product.

Depending on the design, dynamic mixers can have multiple rotors and stators to increase efficiency.

Areas of application

- Food industry:

- Production of sauces, mayonnaise, creams, yoghurts, and beverages.

- Homogenising milk or cream.

- Pharmaceuticals:

- Preparation of sterile solutions, ointments, gels.

- Mixing active ingredients with excipients.

- Cosmetics industry:

- Production of creams, shampoos, lotions, and toothpastes.

- Emulsification of oils and water components.

- Chemical industry:

- Mixing paints, varnishes, adhesives, resins.

- Dispersing solid particles in liquids.

- Oil and gas industry:

- Preparation of lubricants, emulsions, drilling fluids.

Features of dynamic mixers

- High intensity of the process:

The interaction of the rotor and stator ensures efficient mixing of even complex media. - Adjustable speed:

Mixers allow you to change the rotor speed, which allows you to adapt the equipment to specific processes. - Precision and control:

They provide control of emulsification, dispersion and homogenisation processes. - Versatility:

They are suitable for use in a variety of media: low-viscosity, high-viscosity, abrasive or mechanically sensitive. - Materials of execution:

They are made of stainless steel (AISI 316L), which meets sanitary standards and provides corrosion resistance. - CIP/SIP support:

Most models are compatible with automatic cleaning and sterilisation systems. - Compactness:

They can be portable or integrated into production lines.

How to choose the right dynamic mixer?

- Product properties:

- Consider the viscosity, density, temperature, and chemical composition of the liquid.

- For sensitive foods, choose mixers with a delicate operating mode.

- Production capacity:

- Calculate the capacity of the equipment based on the volume to be processed.

- Type of rotor-stator system:

- Single-stage models are suitable for simple processes.

- Multi-stage mixers provide more intensive processing and are used for complex tasks.

- Materials:

- Choose stainless steel for food and pharmaceuticals.

- Use special coatings for aggressive environments.

- Management system:

- Check the possibility of automation and integration into existing production lines.

- Additional features:

- Availability of a cooling or heating system if the process requires temperature control.