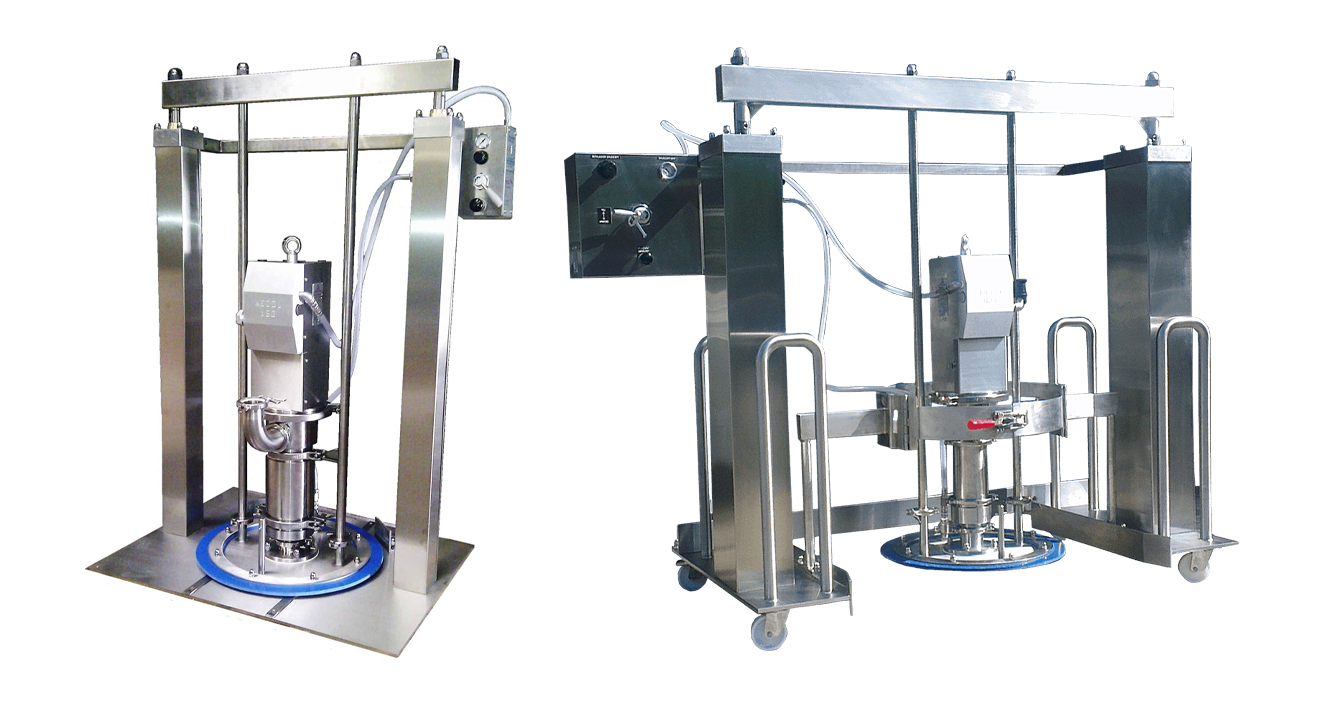

Pumping systems operate with a specialised pump that is installed directly into the drum or other container. The liquid is sucked by the pump through a submersible tube and fed into the outlet pipe.

The main stages of work:

- Immersing the pump in the barrel: The pumping tube is lowered into the interior of the container.

- Liquid suction: The pump's working element creates a vacuum or mechanical pressure to lift the liquid.

- Transportation: The liquid is pushed through the outlet to the desired delivery point.

Components of the pumping system

- Pump:

The central element that determines performance and fluid compatibility. The type of pump is selected according to the characteristics of the fluid:- Centrifugal pump: For liquids with low viscosity.

- Gear pump: For thick and viscous liquids.

- Diaphragm pump: For aggressive, abrasive or viscous media.

- Screw pump: For use with delicate products.

- Immersion tube:

The tube that goes down into the barrel. It is made of chemically resistant materials such as stainless steel, polypropylene or PVDF. - Reason:

- Electric drive: Delivers high performance and is suitable for continuous operation.

- Pneumatic drive: It is used in explosive atmospheres.

- Manual drive: An economical solution for small volumes.

- Controllers and filters:

Ensure accurate fluid delivery and cleaning before transport. - Additional accessories:

- Adapters for different types of containers.

- Fluid supply hoses.

- Automatic shutdown systems when the set level is reached.

Areas of application

- Chemical industry:

Pumping acids, alkalis, solvents and other aggressive substances from sealed containers. - Pharmaceuticals:

Precise dosing of active ingredients from containers to production lines. - Food industry:

Pumping out syrups, oils, liquid dough, dairy products and other foodstuffs. - Cosmetics industry:

Work with thick masses such as creams, shampoos, gels, oils. - Oil and gas industry:

Pumping fuels, oils, greases and other petroleum products. - Cleaning systems:

Pumping out reagents, detergents and disinfectants.

Features of pumping systems

- Compatible with various liquids:

Thanks to a wide range of materials, the systems are suitable for transporting aggressive, viscous, thick, toxic and delicate liquids. - Mobility:

The systems are easy to install and move between different tanks. - Energy efficiency:

Modern models consume minimal energy while providing high performance. - Durability:

High-quality materials ensure a long service life, even in harsh environments. - Performance control:

The pumping speed can be adjusted to suit the fluid characteristics.

How to choose the right barrel pumping system?

- Fluid characteristics:

- Take into account the viscosity, chemical composition, temperature and aggressiveness of the working environment.

- Material of execution:

- Polypropylene or PVDF for aggressive substances.

- Stainless steel for food or petroleum products.

- Productivity:

- Select a pump with the appropriate flow rate for the volume of the vessel.

- Type of drive:

- Electric for large volumes.

- Pneumatic for explosive environments.

- Manual for cost-effective solutions.

- Protection systems:

- Availability of dry running protection, automatic shutdown or overflow sensors.