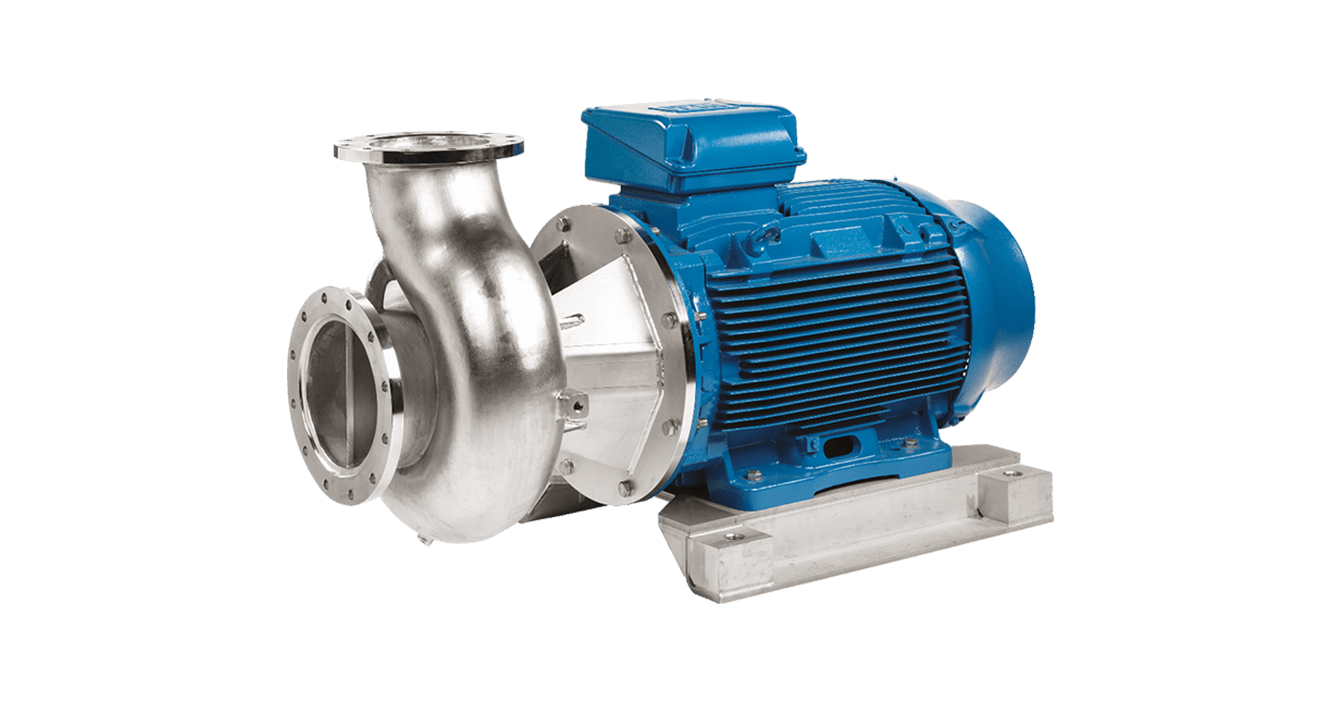

Centrifugal pumps are one of the most common types of pumps used in various industries. Their principle of operation is based on the use of centrifugal force generated by the rotation of the impeller. Due to their simple design, high performance, and reliability, these pumps are an ideal choice for transporting large volumes of low-viscosity liquids.

The main differences from a hygienic centrifugal pump

| Characteristics | Hygienic pump | Industrial pump |

|---|---|---|

| Body materials | Stainless steel AISI 316L | Cast iron, steel, bronze |

| Design | No dead spots, smooth surface, easy cleaning | Focus on durability, without emphasis on hygiene |

| Standards | EHEDG, FDA, 3-A compliance | May not meet sanitary standards |

| Products for transportation | Food, pharmaceutical, cosmetic products | Water, chemical solutions, technical fluids |

| Sterilization and cleaning | CIP/SIP compatibility | Not supported |

| Price | Higher due to the use of special materials and design | Usually lower due to simpler construction |

Application of centrifugal pumps

Centrifugal pumps are widely used in the following industries:

- Chemical industry: for pumping solutions, acids, alkalis and water.

- Food industry: for transporting juices, milk, water and other liquids with low viscosity.

- Pharmaceutical industry: for water purification, dissolving components and cooling.

- Water treatment systems: for pumping drinking or waste water.

Features of centrifugal pumps

The main features of centrifugal pumps are:

- The ability to pump large volumes of liquids efficiently with minimal energy consumption.

- Simple design that includes:

- Body

- Impeller

- Shaft

- Motor

- The use of various materials (stainless steel, cast iron, bronze, plastic), which allows working with aggressive, corrosive and neutral liquids.

Advantages and disadvantages of centrifugal pumps

Advantages:

- High performance and efficiency when transporting large volumes of liquid.

- Simple design and easy maintenance.

- Low noise level during operation.

- A wide range of models for different operating conditions.

- Affordable cost compared to other types of pumps.

Disadvantages:

- Not suitable for use with viscous liquids or suspensions.

- Sensitivity to changes in hydraulic conditions (e.g., excessive suction).

- The need to pre-fill with liquid to start (they do not work “dry”).

- Limited ability to create high pressure.

How to choose a centrifugal pump: key points

- Type of liquid: Consider the chemical composition, temperature, and aggressiveness of the fluid.

- Productivity: Make sure that the pump is capable of pumping the required volume of fluid in the specified time.

- Working pressure: Select the pump that matches the required head level.

- Material of manufacture: The housing and impeller must be resistant to liquid.

- Energy consumption: Pay attention to the energy efficiency of the pump.

- Installation conditions: Ensure that there is sufficient space and connection type for installation.

- Protection against dry running: Ensure the longevity of the pump by selecting a model with the appropriate protection system.