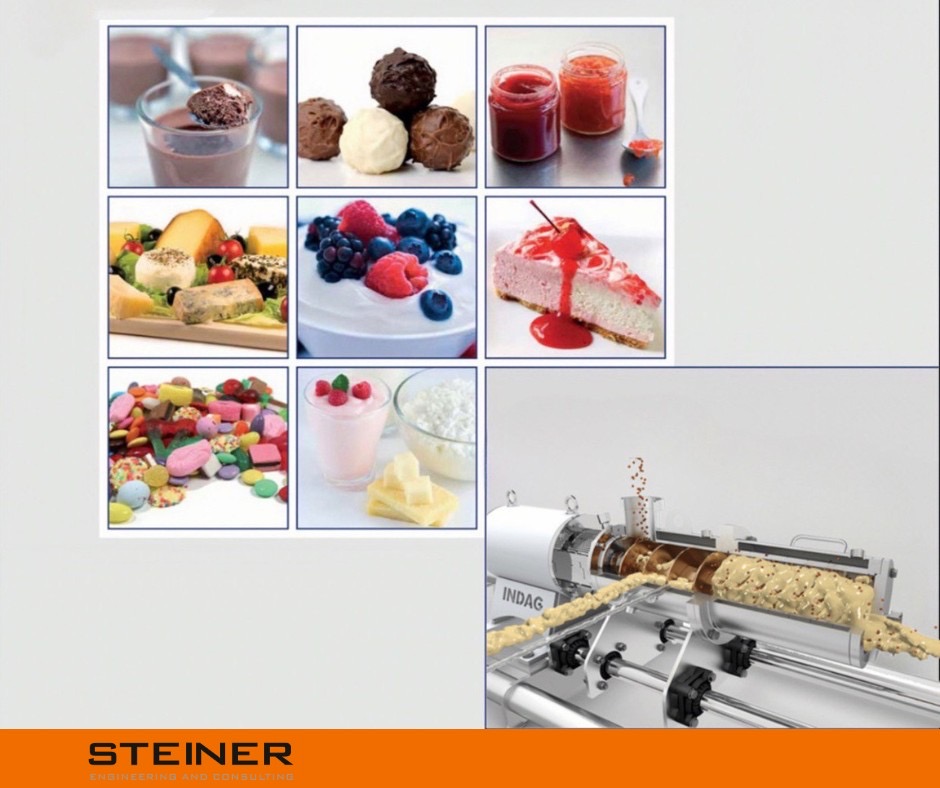

Do your desserts require careful mixing? Then we know how to turn them into a work of art.

Steiner offers efficient industrial mixers for the preparation of emulsions:

- Dairy products: yoghurts, cottage cheese, fresh cheeses, whipped cream.

- Confectionery: creams, fillings, chocolate, chewing products, nougat, marshmallows.

- Baking: biscuits, cupcakes, waffles.

- Chemicals and petroleum products: wax, oil, polymers, glue, bitumen, latex, plastics, paints, varnishes.

- Cosmetics: creams, soaps.

- Environmental products: flocculants, sludge.

With Steiner's DLM/FS dynamic mixers from Indag Maschinenbau GMBH (Germany) for the seamless mixing of liquids with solids in both the food and non-food industries, emulsifying, dispersing and foaming of various flowable products, there is no need to waste valuable time and money on outdated equipment.

Today, most mixer suppliers focus exclusively on homogenisation and high-intensity mixing with very high shear. We offer mixers that can mix dry ingredients, liquids and gases at any desired mixing intensity.

One of the most common applications for mixers is the mixing of dairy products, such as yoghurt with fruit fillings. When mixing such ingredients, hygiene and a comfortable mixing process are of paramount importance. Since INDAG mixers are sterile designs with no rinsing areas, standard one-piece washing and full drainage ensure the safety of the production process.

Depending on the size of the mixing elements, solids can be mixed gently or at a higher shear rate. This preserves the integrity of the solids. Such particles include corn flakes, cocoa powder, nut pieces, chocolate pieces, raisins and many more. They can be up to 20 mm in size (ball diameter) or in powder form. You can also mix solids into the foam without damaging the foam material. There are virtually no limits to recipes, in particular:

- For example, to mix cornflakes in white chocolate, the white chocolate is fed into the inline mixer at 37-40°C by an external pump. The solid ingredients are fed into the inline mixer via a solids feeder (dosing scales). There can be two or more solids streams at the same time. The rotating mixer feeds the product with a screw auger and mixes it simultaneously with the rotor and stator elements. The mixing procedure has to be very gentle, as chocolate is very sensitive to heat and shear. Therefore, the temperature must be controlled at all times. As a result, the product comes out of the mixer gently, homogeneously and almost without pressure.

- For example, by mixing egg yolk and vinegar solution, a premix is created for the production of mayonnaise.

- What about foaming (aerating) marshmallows? This is where the protein, a mixture of sugar, water, glucose and air are mixed to form a fine foam.

- Even mixing a sugar solution with a flavouring homogeneously is no problem for INDAG mixers.

- The use of mixers is also unlimited in the production of processed cheese. Here, the cheese is effectively cooked with superheated steam. The DLM/S type mixer features patented star-shaped mixing elements on the rotor and in the stator (housing). The star shape is extremely stable and also allows mixing products with high viscosities (over 10,000,000 mPa-s). The mixing energy is introduced into the product very efficiently. The rotor and stator can be designed for cooling/heating. The mixers have a modular design, with six diameters and five lengths (number of mixing stages) available. Each mixer can also be upgraded from a single-acting mechanical seal to a double-acting mechanical seal.

So, today, the main advantages of INDAG mixers are:

- small volume of product in the mixing chamber, which results in less waste during washing.

- small dimensions and weight, which makes it easy to install and maintain.

- easy replacement of a single shaft end seal with a double shaft end seal.

- Possibility of horizontal or vertical installation.

- easy rotor change without changing the mixer design.

- The German manufacturer INDAG is ready to develop an individual mixer design that would be 100 % in line with the client's process.

So, let's work with faith in our VICTORY! For further discussion of your project, please contact us at: + 38 (044) 390 73 38. We are in touch every day, as we are constantly supporting the production industry, each other and our mother Ukraine!