Gear pump is one of the most common types of pumps used to transfer liquid or viscous substances. Its gear-based design ensures an even and continuous flow, allowing for a stable system pressure. The ability to handle liquids of varying densities and viscosities makes these pumps ideal for many industrial applications. Available at. offering a range of components, we are ready to handle not only their selection but also the prompt delivery across Kyiv and Ukraine. Moreover, we guarantee a full range of accompanying services. All separator parts presented in the catalog are affordably priced and come with mandatory warranties, making the choice in our favor a reasonable and cost-effective solution allows purchasing equipment at no extra cost to the budget, regardless of the volume of the ordered batch.

Особливості та характеристики шестерних насосів

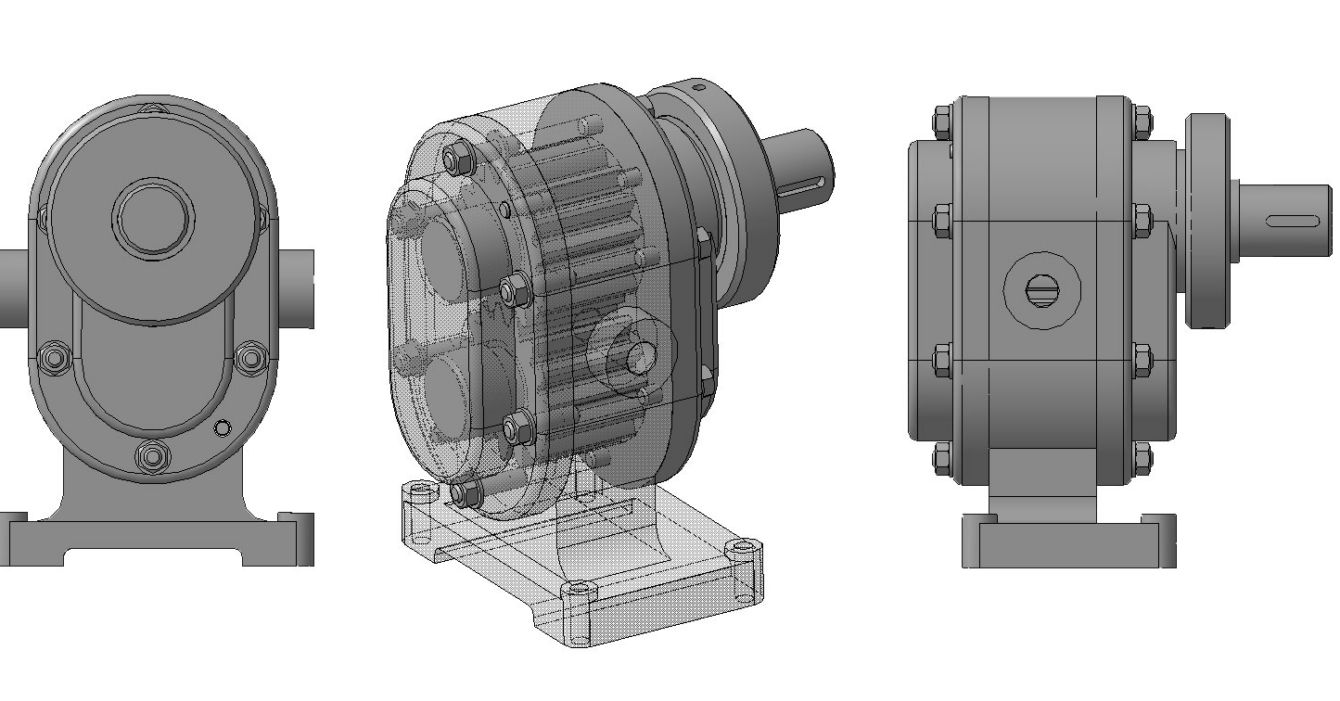

Gear pumps are characterised by a simple yet robust design, consisting of a pair of gears that rotate to create the pressure required to pump the liquid. This type of pump operates with high dosing accuracy and uniform flow, which is important when transporting sensitive substances. Due to the absence of significant component wear, they offer long and stable operation without the need for frequent maintenance.

In addition, gear pumps are capable of handling highly viscous liquids as the gear design creates an effective sealing system. This is particularly useful when handling thick substances, with the gears interacting with them to ensure a constant flow without the risk of clogging or blockage. The versatility and robustness of the design allows these pumps to be used in many technological processes requiring high reliability and performance.

Where and why gear pumps are used

Available at competitive prices, this type of pump is indispensable for the following applications:

- Pumping viscous liquids. Ensure stable operation with high-density liquids without loss of performance.

- Precise dosing of mixtures. Allows you to control the feed volume, which is important for processes with high process accuracy requirements.

- Transport of sensitive substances. Maintain a uniform flow, eliminating peak loads and damage to the substance.

- Lubrication of mechanisms. Provide a stable supply of lubricants, reducing equipment wear.

- Pumping aggressive compounds. Thanks to their resistant materials, the designs are suitable for use with corrosive or active substances.

Offering our partners certified products, we guarantee their reasonable price, taking care of fast delivery of orders Kyiv and Ukraine. Do you still have any questions? Contact us - our team will help in any situation.