The production of pet food is a complex technological process that requires precise control of parameters, stable product quality, compliance with food safety standards, and high production efficiency. Selo, a leader in the development of technological lines, offers integrated solutions for equipment and automation of wet pet food production lines for dogs, cats, and other pets.

What is the technological cycle of wet pet food production (pet food processing) and why is it important for manufacturers?

Pet food processing — is a complete cycle of processing raw materials into finished animal feed, which includes the following key stages:

- preparation of ingredients and recipes;

- emulsification and mixing;

- optimal heat treatment (often through steam tunnels);

- cutting/shaping of particles;

- cooling and buffering;

- packaging and sterilisation.

The right technology ensures the preservation of nutritional properties, textural uniformity and taste characteristics of the product, which is critical for the health of dogs and cats. According to industry sources, the quality of the technological cycle directly affects the bioavailability of nutrients, the stability of trace elements and the safety of feed.

Selo solution for pet food processing

Selo offers complete wet pet food production lines and individual technological modules that can be adapted to your needs — from startups to large-scale productions.

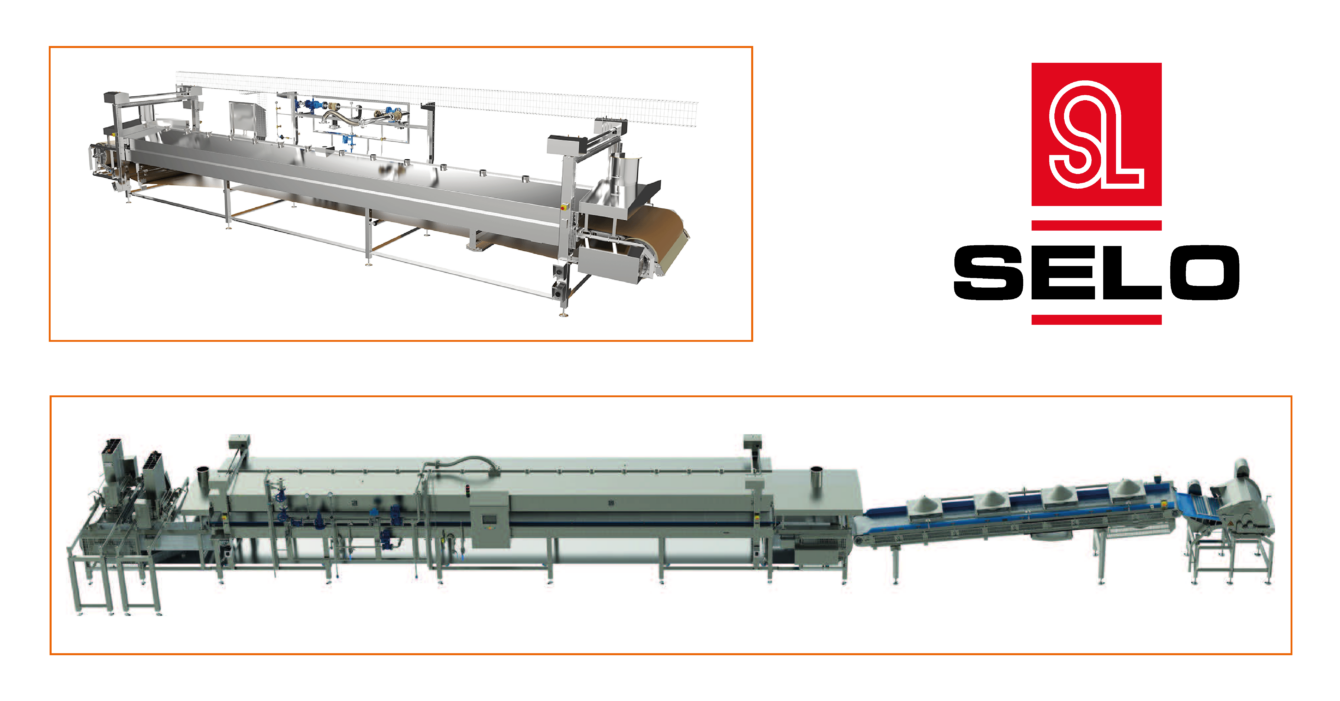

Steam tunnel — the heart of the production line

One of the key technologies is steam tunnel treatment, where the emulsion is smoothly moved by a conveyor under the influence of steam until the specified degree of heat treatment is achieved. This allows:

- optimally prepare feed emulsions and pieces;

- preserve the colour, taste and texture of the product;

- ensure the safety and stability of microbiological indicators.

This technology is the standard for the production of chunk-type wet feed, which is well accepted by animals and meets modern market requirements.

Advantages of Selo production lines for pet food

Flexibility and scalability

Selo lines are available in a wide range of capacities — from 250 to 5000+ kg/hour, allowing you to tailor production to any volume, from small to high tonnage.

Product quality and safety

The production lines are designed in accordance with EHEDG hygienic standards, which simplifies equipment cleaning, minimizes the risk of cross-contamination, and ensures compliance with international pet food safety requirements.

Integration and automation

The systems are easily integrated with packaging lines (pouches, cans, trays) and provide a complete process from raw material processing to finished products, including buffer systems to maintain continuous production.

Process optimisation

Selo solutions enable you to:

- optimise heat treatment and emulsification;

- reduce time and energy expenditure;

- to increase the efficiency and productivity of pet food production.

Main series of pet food equipment from Selo

Selo offers several production line options depending on the capacity and needs of the enterprise:

Ocelot Series

A compact solution for small and medium-sized production facilities:

- up to 300 kg/hour;

- easy to maintain, effective in basic processes.

Cheetah Series

A line for medium volumes with high flexibility in process parameters, including shape and colour options.

Serval Series

Medium and large class solutions with multi-format production capability (up to several products simultaneously).

Amur Series

Powerful lines for high-tonnage wet feed production (up to 5,000 kg/hour).

| Ocelot | Cheetah | Cheetah XL | Serval | Serval L | Serval XL | Amur | Amur XL | |

|---|---|---|---|---|---|---|---|---|

| Range Chunk Capacity (kg/hr) | 250 | 400-600 | 600-750 | 1000-1500 | 1500-2000 | 2000-2500 | 3000-3500 | 4000-5000 |

| Type of steam tunnel belt | Teflon | SS316 / Teflon | SS316 / Teflon | SS316 / Teflon | SS316 | SS316 | SS316 | SS316 |

| Metal detection | O | O | O | O | O | O | O | O |

| Coloring option | N/A | O | O | O | O | O | O | O |

| No. of extruders / chunk shapes (optionally) | 1 | 1 | 1 | 1 (2) | 1 (2) | 1 (2) | 2 (3) | 2 (3) |

| Cutter - Single shaft | S | S | S | S | S | S | S | S |

| Cutter - Double shaft | N/A | N/A | N/A | O | O | O | O | O |

Animal feed production: important aspects of technology

Modern pet food production technologies must take into account not only the essence of the recipe, nutritional value and taste, but also regulatory requirements for food safety, hygiene and shelf life. Selo's automation and integrated solutions help manufacturers:

- reduce the risks of biological contamination;

- improve portioning accuracy and control of processing cycles;

- reduce waste and improve profitability.

Selo equipment and technologies for pet food processing enable manufacturers to produce high-quality, safe, and consistent pet food that meets the demands of the modern market. Fully integrated solutions — from recipe development to packaging — ensure efficiency, flexibility, and quality control at every stage of production.