Steiner Ukraine officially represents the Italian manufacturer Orobica in Ukraine, supplying Ukrainian enterprises with high-quality seals and plates for heat exchangers from leading global brands.

Orobica PlastGom: Leader in the production of seals for heat exchangers

The Italian company Orobica PlastGom has established itself as a reliable manufacturer of gaskets for plate heat exchangers, working with leading global brands. The company specialises in the production of compression and injection gaskets suitable for any type of heat exchanger.

Technological advantages of Orobica production

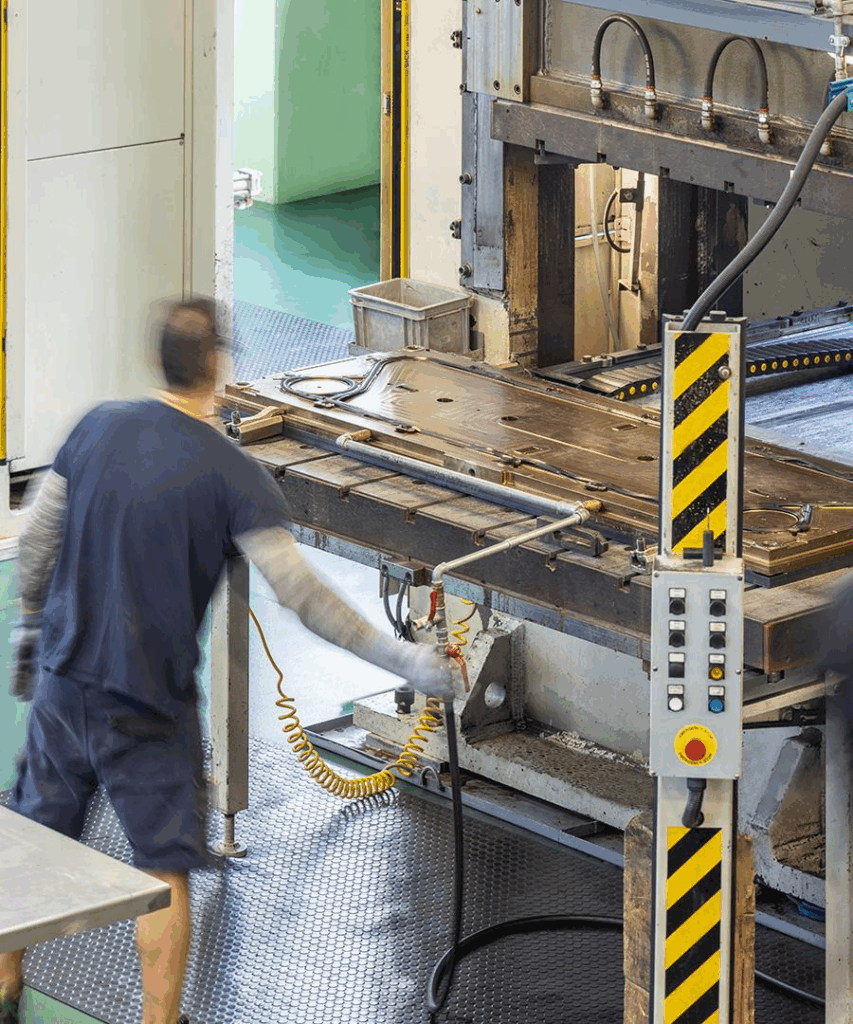

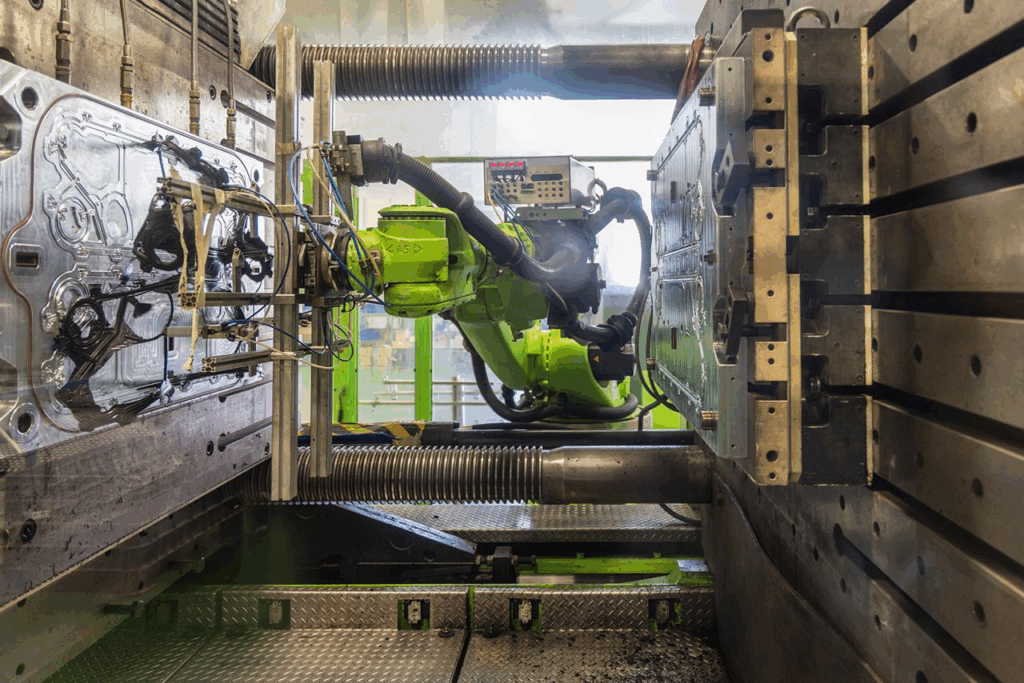

Innovative production technologies ensure high product quality. The company's technical office works with customers to develop seal models from simple drawings or samples. Using modern equipment and qualified personnel, Orobica manufactures seals by compression or injection, suitable for any type of heat exchanger.

Continuous research and development: in partnership with leading global research laboratories, the company is constantly improving its formulations to increase durability and performance even in the most challenging industrial environments.

A wide range of materials for different operating conditions

Specialised materials for the food industry

Orobica offers a wide range of materials certified for use in the food industry:

| Chemical name | ASTM D-1418-79 | Temperatures °C |

|---|---|---|

| BUTADIENE - ACRILONITRILE | NBR STD FOOD | -20 + 120 |

| BUTADIENE - ACRILONITRILE | NBR HT FOOD | -20 + 140 |

| BUTADIENE - ACRILONITRILE | NBR HT IND | -20 + 140 |

| BUTADIENE - ACRILONITRILE - IDROGENATA | H-NBR | -40 + 150 |

| CLOROPRENE | CR | -40 + 100 |

| ISOBUTILENE - ISOPRENE | IIR | -40 + 110 |

| ETILENE - PROPILENE - DIENE | EPDM STD | -40 + 120 |

| ETILENE - PROPILENE - DIENE | EPDM STD FOOD | -40 + 120 |

| ETILENE - PROPILENE - DIENE | EPDM HT FOOD | -40 + 150 |

| FLUORURATA | FKM “A” STD | -15 + 220 |

| FLUORURATA | FKM “A” FOOD | -15 + 220 |

| FLUORURATA | FKM “GF” | -8 + 200 |

| FLUORURATA | FKM “GLT” | -30 + 200 |

Areas of application for Orobica seals

Production of alcoholic and non-alcoholic beverages

In beverage production, Orobica seals ensure stable operation of pasteurisers and heat exchangers. NBR FOOD and EPDM FOOD materials guarantee no migration of substances into the product, preserving the original taste of beverages. High resistance to CIP/SIP procedures ensures compliance with sanitary standards.

Dairy industry and dairy product processing

Temperature resistance of materials is critically important for the dairy industry. EPDM HT FOOD (-40°C to +150°C) and FKM ‘A’ FOOD (-15°C to +220°C) seals are ideal for milk pasteurisation and cheese production. The materials do not affect the quality of dairy products and are resistant to aggressive cleaning agents.

Pharmaceutical industry

The highest standards of cleanliness are used in pharmaceutical manufacturing. Seals made of H-NBR and FKM materials ensure process sterility at high temperatures and pressures. Resistance to steam sterilisation and chemical disinfectants is critical in this industry.

Chemical industry

Orobica offers specialised materials for working with aggressive chemical environments. FKM options withstand the effects of acids, alkalis and organic solvents at temperatures up to +220°C. H-NBR materials provide reliable sealing under high mechanical loads.

The importance of choosing the right materials

Seal selection criteria

The correct selection of sealing material is critical for the efficient operation of the heat exchanger. When selecting seals, the following must be taken into account:

- Temperature stability: the material must withstand operating temperatures without deformation or loss of properties.

- Chemical resistance: the seal must be resistant to working environments, including acids, alkalis and organic solvents.

- Mechanical stability: ability to withstand pressure and mechanical loads during operation.

- CIP/SIP compatibility: resistance to on-site cleaning procedures and steam sterilisation.

Consequences of incorrect selection

Incorrectly selected seals can lead to:

- System leaks

- Product contamination

- Premature failure of equipment

- Increase in maintenance costs

Advantages of cooperation between Steiner and Orobica

Technical expertise

Steiner Ukraine provides comprehensive technical support:

- Professional advice on material selection

- Analysis of operating conditions

- Recommendations for the optimal choice of seals

- Technical support after sale

Wide compatibility

Orobica gaskets supplied by Steiner Ukraine are compatible with heat exchangers from leading global manufacturers:

- Alfa Laval

- GEA Kelvion

- API Schmidt

- Fischer

- APV

- Danfoss

Quality assurance

All Orobica seals undergo strict quality control and comply with international standards. The company guarantees the stability of the materials' properties and their compliance with the declared characteristics.

Individual approach to each client

The Orobica technical office, in cooperation with Steiner Ukraine specialists, develops individual solutions for each customer. The ability to manufacture seals according to individual drawings or samples ensures precise compliance with the needs of a specific production.

Conclusion

The partnership between Steiner Ukraine and Orobica PlastGom provides Ukrainian enterprises with reliable, high-quality seals for heat exchangers. The combination of Italian manufacturing quality and Ukrainian technical expertise guarantees optimal solutions for any industrial needs.

For detailed advice on selecting gaskets and plates for your heat exchangers, please contact the specialists at Steiner Ukraine. Our team of experienced engineers will help you find the optimal solution for your specific production needs.

Read also “Signs of heat exchanger wear: when it's time to replace spare parts“