In meat processing and pet food production, the real bottleneck is often not grinding or mixing, but defrosting frozen blocks. Conventional tempering rooms require large floor space, consume significant energy, complicate plant layout, and can cause weight losses due to drip loss (release of meat juices).

An alternative is vacuum defrosting with direct steam injection from below, which allows raw material to be taken directly from the freezer and prepared for further processing in minutes rather than hours.

What is scanDefrost and what is it for?

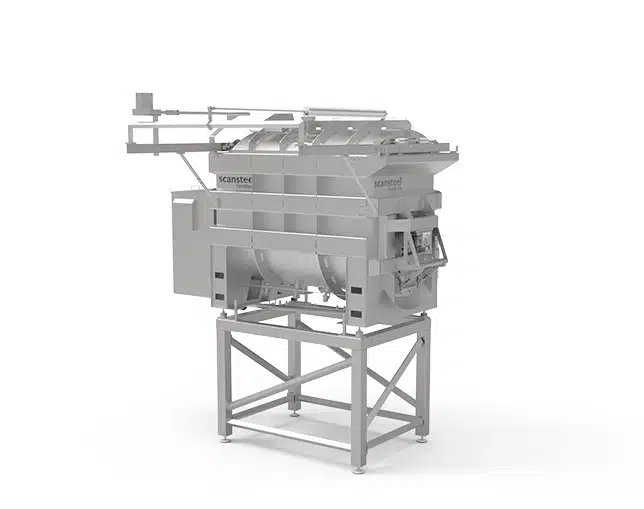

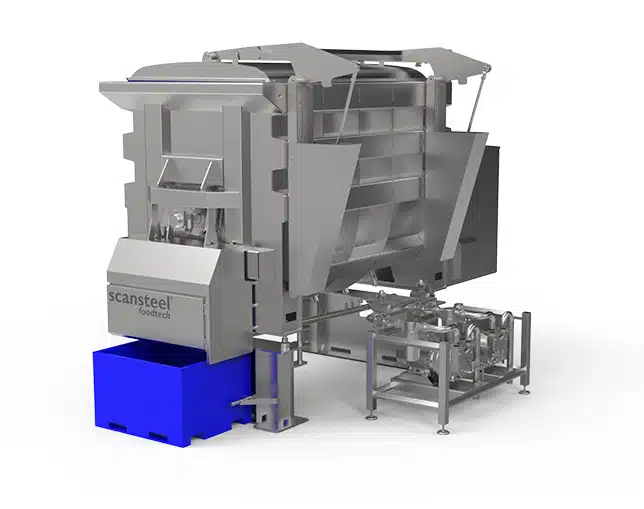

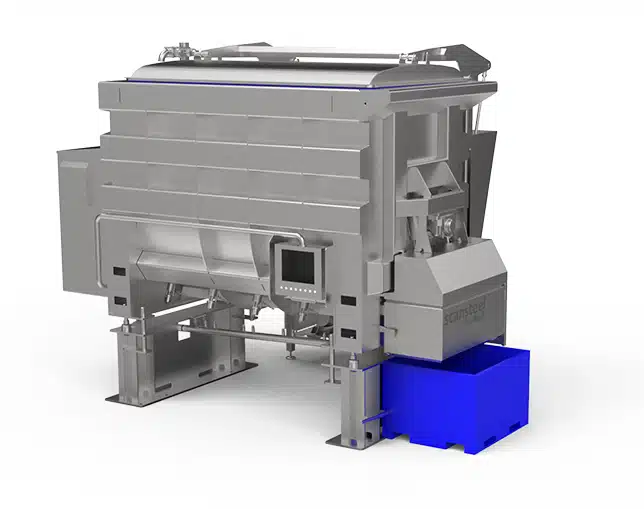

scanDefrost (:contentReference[oaicite:0]{index=0}) is a series of systems designed for rapid defrosting of pre-ground / crushed frozen blocks of meat and poultry, as well as frozen bone blocks. Importantly, the system processes raw material directly from the freezer at temperatures down to −30 °C and completes defrosting within minutes.

In industrial logistics, this means one simple thing: fewer “buffers” in the form of tempering/defrosting rooms and greater control over production planning — knowing exactly when and which raw material can actually be fed into the process.

How vacuum defrosting with steam supply from below works

Key elements of the technology:

- Vacuum in the defrosting chamber

- Direct steam injection from below

- Uniform distribution of steam (10 nozzles — 5 on each side).

The result is fast and even defrosting without having to keep the raw materials in ‘warm’ rooms for long periods of time.

Speed: what does ‘in minutes’ mean in practice?

The manufacturer indicates a benchmark: defrosting from −18 °C to +2 °C without ice crystal formation within 13–15 minutes (as a general capability of defrosting solutions).

Important: actual time always depends on the type of product, initial temperature, block geometry/density, and load. But the ‘minutes, not hours’ approach itself is about a different level of process control.

What problems does scanDefrost solve in classic defrosting?

1) Loss of weight and quality (drip loss)

Among the key advantages of scanDefrost, the manufacturer directly states: NO driploss / no juice loss — i.e. defrosting without liquid loss, which directly affects yield and economy.

2) Preservation of technological properties

This refers specifically to the ‘softness’ of the method:

- does not cause protein denaturation,

- does not cause discolouration,

- preserves the binding properties of meat (critical for minced meat and emulsion products, as well as pet food).

3) Logistics and planning

scanDefrost is positioned as a solution that allows processing raw materials without intermediate tempering, simplifying planning and reducing dependence on ‘heat storage facilities

4) Resources: time, space, energy

Among the general advantages: significant savings in time, space and energy.

- up to 50% savings in space and electricity.

Where it has the greatest effect: typical scenarios

scanDefrost is most often considered, when you have at least one of the following:

- production works with frozen meat raw materials / poultry / bone blocks;

- it is necessary to reduce stocks in tempering and the space allocated for them;

- critical repeatability of batches (texture, viscosity, colour);

- important product output and minimisation of liquid loss.

Model range and scaling

Steiner offers scansteel foodtech defrosting systems with a range of capacities from 2,000 to 12,000 litres, (configurations available: 2000/6000/9000/12000 litres)

In practical terms, this means that solutions can be tailored to your volume — from limited batches to large batches for high-capacity lines.

How to choose a defrosting system for your production

To quickly and correctly select the configuration, it is usually sufficient to have information about:

- Type of raw material: meat/poultry/bones, condition (pre-ground or not), temperature from the freezer.

- Target temperature after defrosting (e.g. to +2°C).

- Partisanship and productivity: kg/hour or tonne/shift + how it's organised for delivery to the next machines.

- Site restrictions: area, communications, integration into the existing line.

Steiner Ukraine specialists will help you draw up a brief technical assignment and select a solution tailored to the actual conditions of your workshop.

If you work with frozen meat raw materials or pet food and want to reduce downtime, costs and increase yield without compromising quality, scanDefrost vacuum defrosting is a solution worth considering when optimising your process.