The right industrial mixer in meat processing and animal feed production solves three tasks simultaneously: fast and uniform mixing, control of mixture structure/density, and hygiene (ensuring that batches do not get “mixed” with one another). The scansteel foodtech range includes single-shaft and double-shaft mixers, as well as double-shaft mixers in a vacuum version and combinations of mixer/grinder — with options for heating/cooling, water dosing, steam injection, and CO₂/N₂ injection.

What is included in the Mixer Programme scansteel foodtech

The manufacturer offers a full range of mixers for the food industry and pet food — from Single Shaft to Twin Shaft, including vacuum versions and modules with a grinder.

1) Side-by-side twin-shaft mixers: TSM / TSMV (vacuum)

TSM (standard) and TSMV (vacuum) have a capacity range from 250 to 6250 liters.

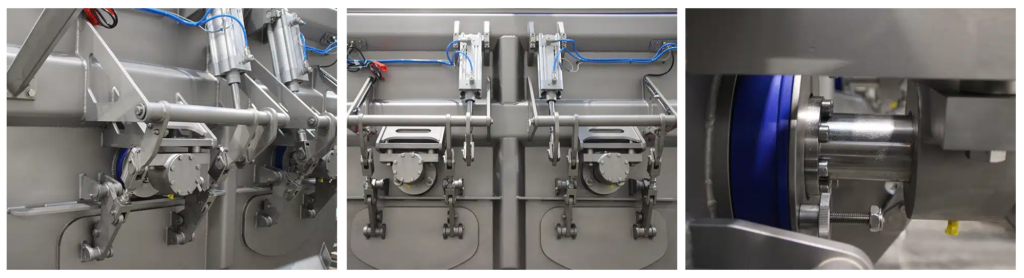

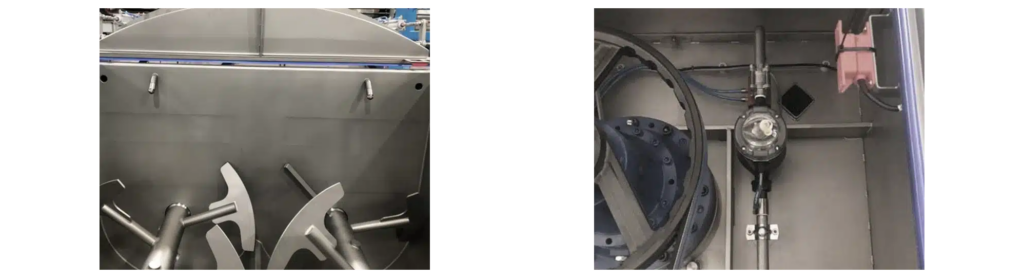

Design: two mixing "wings" side by side at the same height, square tank, speed control through 2 frequency converters.

Four standard rotation directions of the wings — effective for different mixing modes.

When to choose vacuum (TSMV): when you need to remove air before emulsifying, filling/syringing, or shaping, as well as when working with "heavy" formulations (e.g., with cooling) is important.

2) Two-axis coupling: TSMI / TSMIV (vacuum)

TSMI (standard) and TSMIV (vacuum) — have a capacity range of 200–12,000 liters, with series configurations also available within the range of 250–6250 liters.

Design: two mixing wings at different heights; square tank; speed controlled by 1 frequency converter.

Modes: 2 rotation directions — from gentle mixing to intense agitation.

Discharge: two outlet flaps for quick unloading or one large central flap.

In the vacuum version, the specified tasks are: premix density control, curing/tumbling, and enhanced protein extraction.

3) Single-shaft mixers: SSM / SSMV (Vacuum)

- SSM and SSMV — have a range 250–12 000 l.

This is an option that makes sense when you need a single-valve design (e.g., for your existing layout or product type), but hygiene, controllability, and cooling/steam options are still important.

4) Mixer/Grinder

The product range includes the TSMG and TSMIG (intermeshing) series — solutions where mixing is combined with grinding, and the discharge can be either through a grinder or also through discharge flaps (depending on the configuration).

Typical applications: for which products is this class of mixers suitable?

scansteel foodtech directly lists the tasks where their mixers are most commonly used: sausage premixes, burger/patty premixes, nuggets (lean and extended recipes), pizza toppings and dry sausage mixtures, vacuumization/tumbling for ham, heating/cooking/cooling, and also premixes for wet and dry pet food.

Why vacuum twin-shaft mixers often ‘win’ in terms of premix quality

Scansteel foodtech vacuum twin-screw solutions have practical effects that are particularly important for meat raw materials and minced meat mixtures:

- removing air before emulsification, forming or filling;

- better protein extraction and activation of salt-soluble proteins (due to the specific action of the wings and high peripheral speed),

- even distribution of spices, additives and liquids.

These are typical ‘problems’ for manufacturers: when the mixture is not uniform, the structure ‘floats’, formation is unstable, and batches differ from each other.

Process options: steam, CO₂/N₂, water dosing, heating/cooling

Equipment features and options that directly affect handling:

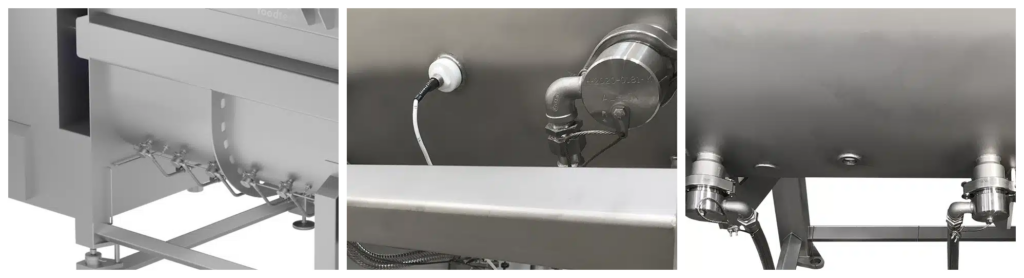

- Steam bottom injection (injection of steam from below through nozzles);

- CO₂ / N₂ cooling systems (top/bottom injection, depending on configuration);

- automatic water dosing;

- double jacket for heating/cooling and insulation

It should be noted that CO₂/N₂ helps achieve the desired viscosity and crystallization for shaping, maintain the shape during further operations; also, cooling reduces bacterial growth and can extend the shelf life of the mixture.

Hygiene and sanitary design: what is important when choosing

For food equipment, it is critical that cleaning is not a ‘heroic’ task, but a standard procedure. Scansteel foodtech equipment has:

- stainless steel construction (frame, body, mixing elements);

- rounded corners and surface treatment for thorough cleaning;

- sealed shaft seals, which are easy to remove for daily cleaning;

- approach to reducing the risk of cross-contamination: minimum product residues, separate/sealed hygienic area, reducing the risk of cross-contamination.

Speed, unloading, handling: what to look for in a vehicle?

A unique advantage of the bathtub design (square) is the very short mixing time and efficient use of space.

Also important:

- short mixing and unloading time;

- cover options, including pneumatically controlled ones;

- levels of automation — from push-button control to PLC systems with touchscreen operator control and digital display of functions;

- CE and safety equipment, low noise level.

How to choose a mixer: a short checklist for manufacturers

To ensure an accurate selection, it is sufficient to collect 10 points:

- Product type: premix/minced meat/emulsion, wet or dry pet food, presence of solid inclusions.

- Is a vacuum necessary? (removal of air before forming/emulsifying/filling).

- Is CO₂/N₂ cooling necessary? (especially for moulded ‘extended’ products).

- Heating/steam: whether it is necessary to heat/cook/maintain the temperature.

- Water and liquid dosing: manual or automatic.

- Partisanship: required mixing volume (litres/batch) and cycles/hour.

- Unloading: two dampers / central damper / outlet through a wolf.

- Level of automation: basic or PLC with operator panel.

- Sanitary requirements: washing mode, sanitisation time, frequency of product replacement.

- Integration into the line: raw material supply (lifts, loading), further emulsification/pumping/forming.