Emulsifiers are devices that ensure a uniform product structure, control particle size, reduce batch-to-batch variations, and increase production efficiency. This is critical for tasks requiring emulsion stability, mixture structure and recipe stability, particularly in the production of minced meat, sausages, pâtés and animal feed.

scansteel foodtech offers a range of high-performance emulsifiers for meat processing, designed and manufactured in Denmark with a focus on reliability, stable operation, ease of maintenance and low operating costs. This equipment is ideal for ensuring a uniform texture of minced meat and stable product quality in the food industry.

What is an emulsifier and why is it important for meat processing and pet food?

An emulsifier is a piece of equipment that converts heterogeneous mixtures into a homogeneous, stable emulsion by intensively cutting and turbulising components such as fat, proteins and liquids. Emulsifiers play an important role in meat processing and pet food production:

- Improve the homogeneity and texture of minced meat or emulsions;

- Improve the binding properties of proteins;

- Ensure uniform particle size throughout the entire batch of product;

- Stabilise the structure of the final product before bottling or moulding.

Emulsifiers are effective for products where a fine and stable structure is important (e.g. pâtés, smooth sauces, wet pet food), as well as for preparing raw materials for further processing.

Range of emulsifiers scansteel foodtech

scansteel foodtech offers several series of emulsifiers to meet the diverse needs of meat product and animal feed production:

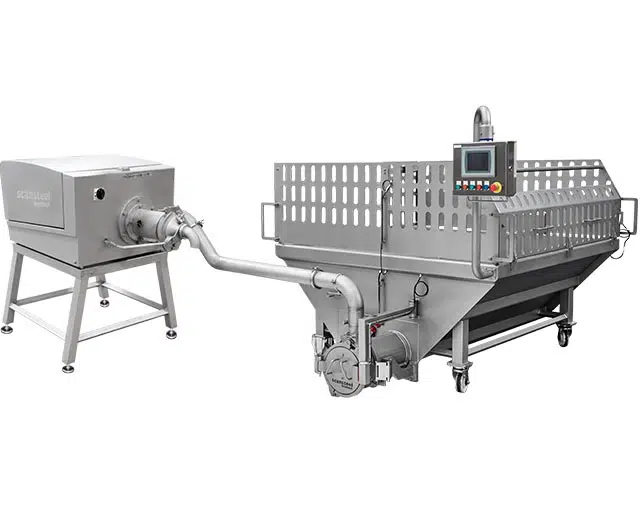

1) scanEmul 175 Series — universal emulsifier with medium productivity

- Productivity: 2,000–7,000 kg/hour

- Motor power: 55 kW, 75 kW or 90 kW

- Feed modes: hopper-fed або pump-fed

- Knife block: system of replaceable blade cassettes (single, double or triple).

The scanEmul 175 is ideal for stable emulsification of various types of mixtures, particularly for medium-sized production facilities. This emulsifier allows you to achieve a homogeneous, fine structure with low variation and batch repeatability. The design provides easy access for maintenance and quick removal of the knife block for cleaning and replacement.

2) QuadroCut / QuadroCutVac 225 Series — heavy-duty solutions for demanding requirements

- Productivity: 2,000–25,000 kg/hour

- Construction: resistant to high loads

- Material: AISI 304 stainless steel

- Processing modes: standard QuadroCut and vacuum QuadroCutVac

- Knife combinations: DoubleCut, TripleCut, QuadroCut, PentaCut.

QuadroCut 225 is a professional emulsifier for heavy-duty and complex tasks in meat processing and animal feed production. It is designed for high-performance tasks with a wide range of recipes where structural homogeneity, stable emulsion quality and repeatability between batches are critical.

Vacuum version QuadroCutVac 225

This model allows air to be removed from the mixture before emulsification, which is particularly important in the production of smooth-type products or wet pet food, where aeration can affect texture quality and organoleptic properties.

Technical details and process control

- Adjustable blade speed up to ~3,000 rpm for optimal particle size;

- Servo control with precise knife shaft positioning with minimal error, ensuring consistent quality and maximum control;

- PLC control and Siemens/Allen Bradley panels for monitoring and adjusting processing parameters;

- Cooled bearings and robust construction for long-term use without overheating.

This makes the QuadroCut and QuadroCutVac series optimal for high-performance food production and pet food lines.

Advantages of using emulsifiers in production

Homogeneity of product structure

Emulsifiers enable consistent particle size across all batches, which is important for stable quality of minced meat, sauces or animal feed.

Improved texture

Evenly ground ingredients ensure better binding and organoleptic properties, especially for pâtés, minced meat and emulsions.

Reduced processing time

Intensive machining allows for shorter process cycles and increased overall line productivity.

Consistent product quality

Since the batch structure is controlled, the manufacturer gets fewer deviations from the recipe and better quality predictability.

Why choose Scansteel Foodtech emulsifiers?

- Danish quality — the equipment is designed and manufactured in Denmark with a focus on quality, durability and ease of maintenance.

- Low operating costs — stable operation and long service life of replaceable blades.

- Flexibility of configurations — the ability to adapt to different product volumes and recipes.

- Integration into the production line — seamlessly integrates with feeders from mixers or pumps, ensuring a continuous process.

How to choose an emulsifier for your tasks

1) Product type

The choice between scanEmul 175 and QuadroCut depends on whether medium performance or high-performance mode is required; QuadroCutVac 225 should be considered when vacuum processing is required.

2) Productivity

Estimate the requirement in kg/hour to select a machine with the appropriate power and set of blades.

3) Structure of the finished product

If you need an ultra-fine texture (e.g. for pâtés or soups), choose models with more blades and a high rotation speed.

Scansteel Foodtech emulsifiers are a reliable technological solution for the production of meat emulsions, minced meat, sauces and pet food, ensuring high product stability, ease of maintenance, flexibility in terms of recipes and effective integration into production lines.

Steiner Ukraine offers a full range of scansteel foodtech emulsifiers for meat processing, pet food and other industries with the option of installation and commissioning.

FAQ: Frequently asked questions

1) What is an emulsifier and why is it important for meat processing and pet food?

An emulsifier is a piece of equipment that mixes insoluble liquids/products, such as water and fat, into a stable emulsion. In meat processing, an emulsifier is necessary for a homogeneous texture of minced meat and to improve the properties of meat and other ingredients, such as spices. In pet food, emulsifiers are used to create homogeneous and stable mixtures.

2) What types of emulsifiers does scansteel foodtech offer and how to choose the right one?

scansteel foodtech offers several series of emulsifiers:

- scanEmul 175 Series — universal emulsifiers for medium productivity (2,000–7,000 kg/hour).

- QuadroCut 225 Series — high-performance models with vacuum processing function (up to 25,000 kg/hour).

- QuadroCutVac 225 — to remove air from the mixture, which is important in the production of wet pet food (wet pet food).

3) Why is it important to have an emulsifier with vacuum treatment for pet food production?

Vacuum emulsifiers remove air from the mixture, which is critical for texture stability and preserving the nutritional properties of animal feed.

4) What is the performance of Scansteel Foodtech emulsifiers and which models should be selected for specific needs?

The performance of scansteel foodtech emulsifiers varies:

- scanEmul 175 Series — up to 7,000 kg/hour for medium-sized enterprises.

- QuadroCut 225 Series — up to 25,000 kg/hour for large-scale production.

- QuadroCutVac 225 — up to 25,000 kg/hour with vacuum treatment for pet food.

5) How do Scansteel Foodtech emulsifiers ensure texture stability and homogeneity?

They operate on the principle of high-speed mixing, which ensures uniform distribution of ingredients and prevents the formation of non-uniform parts in the final product.