The modern industry is on the verge of fundamental changes in approaches to sterilization and pasteurization. In a world where product quality and safety are becoming the number one priority, industrial autoclaves are transforming from simple equipment to a strategic tool for competitiveness. According to leading analytical agencies, the global autoclave market is showing impressive growth - with a projected increase to $2.65 billion in 2025 and further growth to $3.89 billion by 2030 at a CAGR of 8%.

For the Ukrainian market, this trend is particularly important in the context of war and a fundamental reorientation of the economy. The hostilities have significantly transformed the structure of domestic consumption: demand for premium food products, delicacies, confectionery, and alcoholic beverages has sharply declined, while demand for long-term storage products and basic food products has increased. At the same time, Ukrainian producers are actively refocusing on exports - in 2024, Ukraine exported 53.9 million tons of grain (20% more than in 2023), and total physical exports increased by 36%.

It is this export orientation that makes sterilization technologies critical for Ukrainian business. Ukraine remains the world's third largest exporter of corn, the fifth largest exporter of wheat and barley, and the leading exporter of sunflower oil. In this environment, the ability to significantly extend the shelf life of products through high-quality sterilization becomes the number one competitive advantage - it allows Ukrainian goods to travel long distances to European, African and Asian markets while maintaining quality and safety.

This is especially true for ready-to-eat foods and canned foods, whose exports are also showing growth even in times of war. The ability to provide a shelf life of 12-24 months instead of the standard 3-6 months opens up new geographic markets and allows Ukrainian producers to compete with global brands through an optimal price-quality ratio.

Revolutionary changes in industrial sterilization

Modern autoclaves are fundamentally different from their predecessors. They are no longer just heat treatment chambers, but complex technological systems integrated into the Industry 4.0 concept. Automated autoclaves, which are estimated to be worth $330 million in 2024, are equipped with remote monitoring systems, real-time analytics, and improved process control.

This technological evolution is especially important for the Ukrainian market, where the recovery of industrial production after difficult times requires the most advanced solutions. The introduction of advanced sterilization systems allows Ukrainian manufacturers not only to restore but also to significantly improve product quality, meeting the highest European standards.

Multisectoral impact of autoclave technologies

Food industry: a new level of safety

In the food industry, autoclaves have become indispensable for ensuring food safety. They allow for the destruction of pathogenic microorganisms, including spores, while preserving the nutritional properties and organoleptic characteristics of the products. Modern systems provide precise control of temperature, pressure and exposure time, which is critical for preserving vegetables, fruits, meat, ready-to-eat meals and animal feed.

Pharmaceutical industry: absolute sterility

In the pharmaceutical industry, autoclaves achieve a sterility level of 10-⁶, which means that the probability of survival of microorganisms is less than one in a million. This is critical for the production of injectables, implants, and other medical devices, where even minimal contamination can have fatal consequences.

Cosmetics and chemical industry

Autoclaves are used in the production of cosmetics, where sterilization of raw materials and finished products ensures consumer safety and extends shelf life without the use of preservatives.

Economic advantages of modern autoclave systems

Investments in modern autoclaves bring a multifaceted economic effect:

Reduced operating costs: Energy-efficient systems reduce energy consumption by 20-30% compared to outdated models.

Increase productivity: Automated cycles reduce processing time and minimize human error.

Reducing rejects: Precise control of process parameters reduces the percentage of defective products by 15-25%.

Compliance with regulatory requirements: Modern autoclaves automatically generate the documentation required for certification and audits.

Steriflow: French excellence in the world of autoclave technology

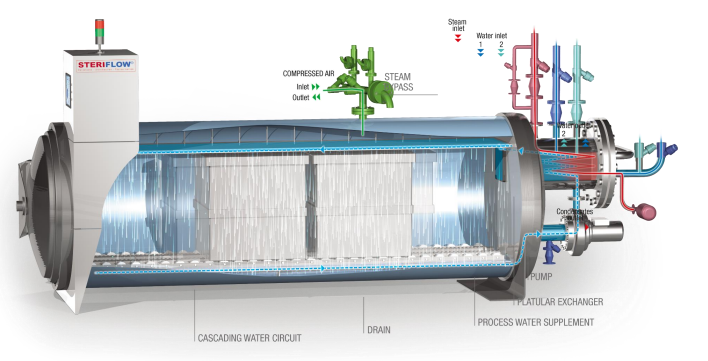

Among the world leaders in the field of industrial autoclaves, a special place is occupied by the French company Steriflow - is a pioneer of innovative solutions with almost 50 years of experience. Located in Roanne, France, the company has become a European leader thanks to its revolutionary patented water cascade technology.

Unique water cascade technology

The Steriflow water cascade system ensures that the heat is distributed absolutely evenly throughout the entire volume of the autoclave. This allows you to:

- Reduce processing time by 20-30%

- Ensure uniformity of the temperature field with an accuracy of ±0.5°C

- Preserve maximum nutrients in products

- Achieve the highest level of energy efficiency

Industry 4.0 innovations

Steriflow autoclaves integrated with Industry 4.0 systems, including:

- Remote monitoring in real time

- Predictive maintenance

- Automatic optimization of processing cycles

- Complete digital documentation of processes

Steiner: your reliable partner for cutting-edge technology

Steiner, as the official representative of Steriflow in Ukraine, offers not just equipment, but comprehensive solutions for production modernization. Thanks to a deep understanding of the needs of the Ukrainian market and a direct partnership with the French manufacturer, Steiner provides:

Professional advice: Detailed analysis of production processes and selection of optimal equipment.

Full service support: From design and installation to staff training and maintenance.

Adaptation to Ukrainian conditions: Taking into account the specifics of local legislation and standards.

Fast return on investment: Thanks to the energy efficiency and high performance of the Steriflow.

The future of autoclave technology

Analysts predict that the coming years will bring revolutionary changes in the field of industrial sterilization. The key trends will be:

- Artificial intelligence: Automatic optimization of processing parameters based on big data analysis

- Environmental friendliness: Minimizing water and energy consumption, using alternative energy sources

- Modularity: Ability to quickly adapt equipment to new products

- Digitalization: Full integration with corporate ERP systems

Conclusions: investing in the future

In today's environment, the introduction of advanced autoclave technologies is not a luxury, but a necessity to ensure competitiveness. Companies that invest in modern equipment today will become market leaders tomorrow.

Partnership with Steiner and the use of Steriflow autoclaves - is a guarantee of receiving the most advanced technologies adapted to Ukrainian conditions. This is an investment not just in equipment, but in the future of your business, product quality, and consumer confidence.

Ready to step into the future of industrial sterilization? Contact Steiner experts today!