How Ukrainian producers increase profits and reduce losses.

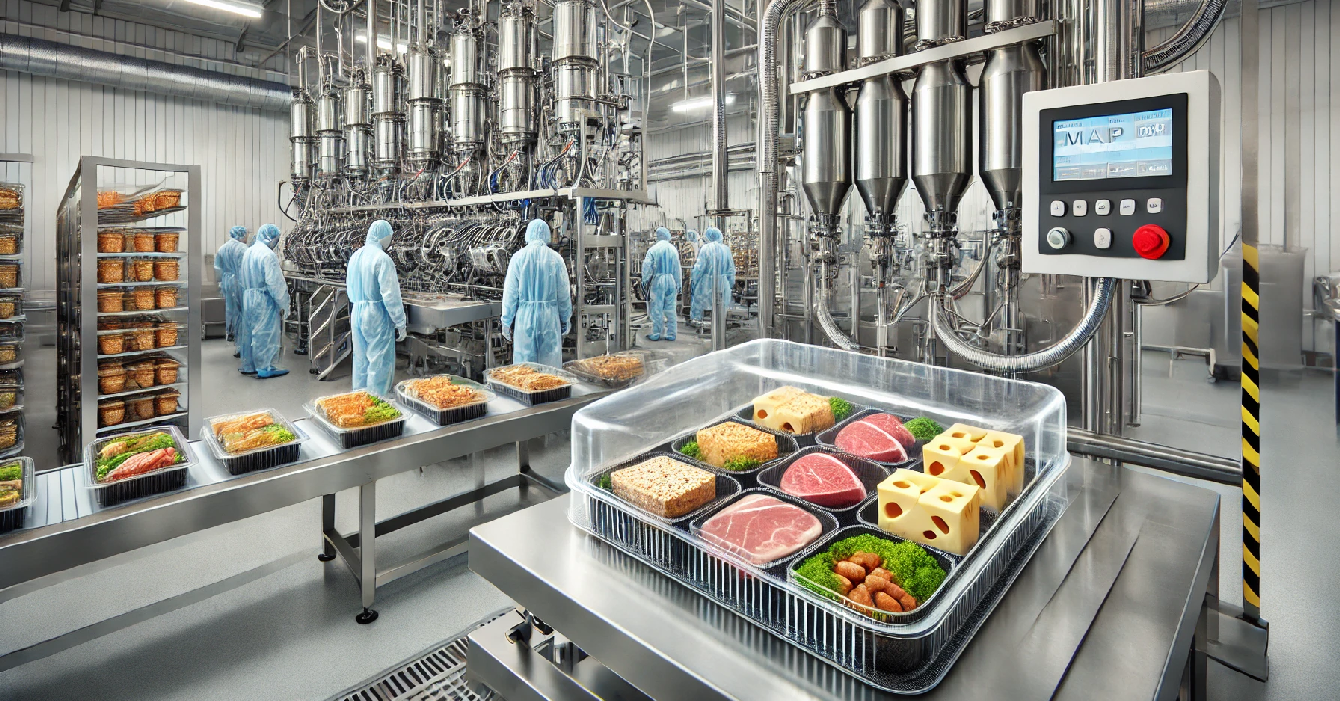

In the food industry, modified atmosphere packaging (MAP) has become one of the key solutions for extending the shelf life of products and ensuring their quality. This technology, which is actively used by leading manufacturers, involves replacing atmospheric air in packaging with a specially selected gas mixture that slows down oxidation processes and reduces the development of microorganisms.

Packaging in a gas environment involves several steps:

- Preparation of packaging and product: The product is placed in special packaging that meets the standards for working with gas mixtures.

- Replacing air with a gas mixture: The air in the packaging is replaced with a gas mixture that is tailored to the specific product. For example, nitrogen and carbon dioxide are ideal for meat products and oxygen for vegetables and herbs.

- Sealing: The packaging is hermetically sealed, preventing air from entering and preserving the selected gas mixture, which helps to maintain product freshness.

Thanks to MGS technology, the shelf life of products is significantly extended without the addition of preservatives. Studies have shown such improvements for staple foods:

- Fresh meat: the shelf life increases from 2-4 days to 5-8 weeks.

- Poultry: from 3-7 days to 7-21 days.

- Sausages: from 2-4 days to 4-5 weeks.

- Hard cheese: from 2-3 weeks to 4-10 weeks.

- Bread: from a few days to 20 days.

- Biscuits: from a few weeks to 1 year.

These indicators confirm the effectiveness of the MGS in maintaining product quality, which significantly reduces waste and increases customer satisfaction.

MGS significantly reduces waste and allows manufacturers to optimise their processes. Estimates show that the use of MGS pays for itself in a few months due to reduced product loss and the ability to sell products for a longer period of time.

The use of MHS in Ukraine is growing rapidly, which is increasing the demand for industrial gases. Cryogenservice, a reliable supplier of gases for MGS, reports that consumption of nitrogen, carbon dioxide and oxygen increased by 15% in 2023, which demonstrates the popularity of this technology among Ukrainian manufacturers.

Steiner offers a wide range of modern packaging equipment that meets all the requirements for packaging in a gas environment.

For example:

- Automatic packaging machines for meat, dairy and confectionery products: allow flexible adjustment to the type of product and the required gas mixture.

- Compact models for small producers: ideal for small and medium-sized businesses where speed and ease of set-up are important.

Reliable service is essential for the stable operation of packaging equipment. Steiner provides a full range of technical support, including regular maintenance, consultancy and training. This allows customers to be confident in the continuity of their production process.

Demand for MGS in Ukraine is expected to grow in the coming years as more and more companies choose sustainable and efficient packaging solutions. Innovations in gas mixtures and quality control technologies will increase productivity and product quality while reducing costs.