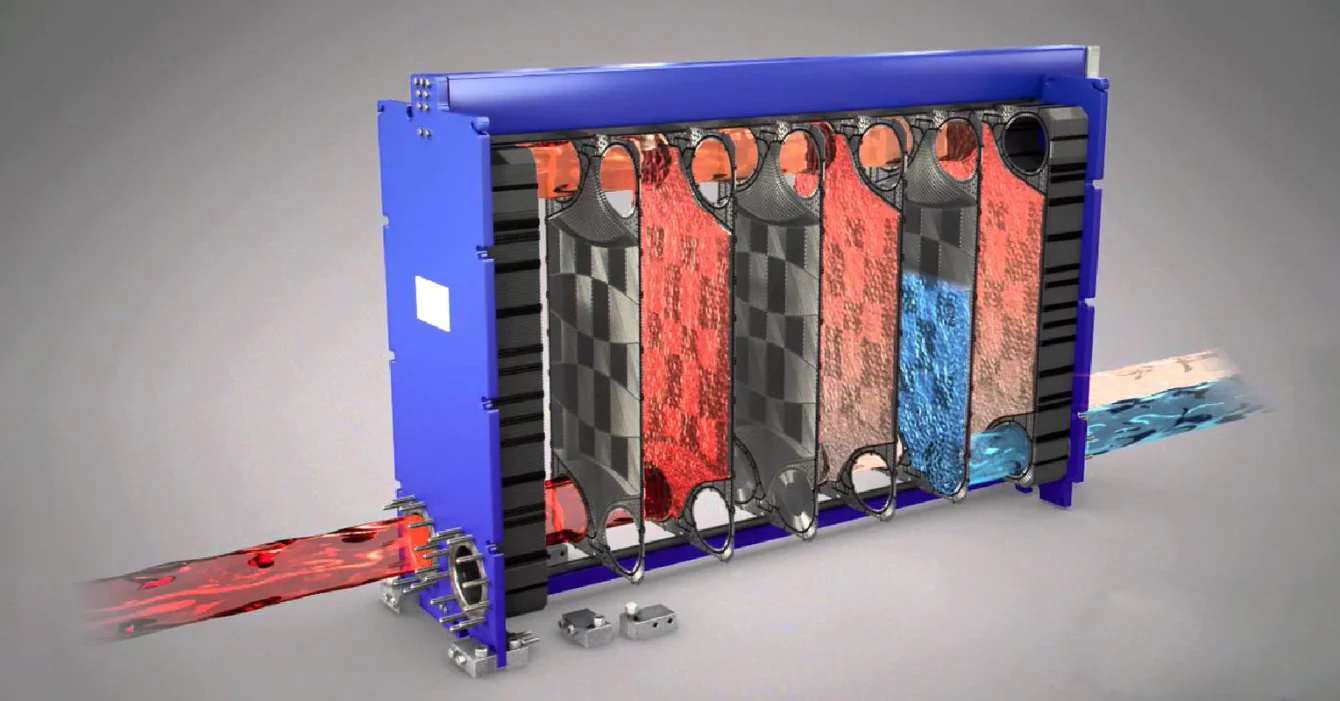

Heat exchangers play a pivotal role in numerous processes by facilitating efficient heat transfer between different media. Their performance directly impacts the stability and energy efficiency of technological operations. However, like any other equipment, they require periodic maintenance. High-quality components for heat exchangersare essential for ensuring safe and long-lasting functionality, and selecting products from trusted brands is always a wise choice.

Heat Exchangers: Ensuring Efficiency and Stability

The plates are a key element of heat exchangers, responsible for the transfer of heat between fluids. They have a special corrugated surface that increases the contact area and facilitates more efficient heat transfer. Their material must be resistant to high temperatures, chemicals and corrosion, and the right choice ensures not only high equipment performance but also reduces the risk of damage during operation.

As for the seals, these heat exchanger parts are responsible for keeping the heat exchanger airtight, preventing leakage of liquids and gases. They are made of materials that can withstand high temperatures and chemicals, providing reliable protection for the system. Improperly selected or worn out, they can cause serious breakdowns, so their regular replacement is essential for the technical condition of the equipment.

How to Choose Components: What to Consider

When selecting spare parts for plate heat exchangers, now available at competitive prices,the following aspects should be taken into account:

- Material of Plates: The material should correspond to the operating conditions of the equipment and offer corrosion resistance.

- Type of Seals: Seals must be able to withstand required temperature and chemical loads.

- Accurate Dimensions: Components should fit perfectly to ensure the system's airtightness.

- Compatibility with Equipment: Ensure the parts match the model and specifications of the heat exchanger.

- Manufacturing Quality: Reliable spare parts from trusted manufacturers last longer and ensure uninterrupted operation.

- Wear Resistance: Components should be designed for long-term use without losing their properties.

The Importance of Timely Maintenance and Repairs

Regular technical inspections can identify wear and tear on parts, such as seals and plates, preventing major breakdowns. During preventive checks, specialists can detect even minor deviations that, over time, could lead to significant issues. This reduces the risk of emergency stoppages and helps maintain the stability of operational processes, improving overall equipment efficiency.

Additionally, regular maintenance extends the lifespan of the unit. Timely and cost-effective replacement of worn components prevents damage caused by neglect. It also ensures stable energy efficiency, as clean plates and functional seals minimize heat loss, reduce associated costs, and support consistent equipment operation over the long term.

In our catalogue, you can always budget-friendly conditions and with a mandatory warranty for the entire range available. By offering certified products, we guarantee their full compliance with industry standards and offering a range of components, we are ready to handle not only their selection but also the prompt delivery across Kyiv and Ukraine. Moreover, we guarantee a full range of accompanying services. All separator parts presented in the catalog are affordably priced and come with mandatory warranties, making the choice in our favor a reasonable and cost-effective solutionprices, taking care of prompt delivery of orders in Kyiv and throughout Ukraine. So don't wait - contact us, our team is always at your service.