Ukraine is one of the world's leading producers of sunflower oil. In our modern world, it is impossible to imagine cooking or industrial food production without oil extracted from sunflower seeds.

We all know that there is crude vegetable oil and refined, or purified, oil. Refining is a complex, multifaceted process of removing unnecessary impurities from oil in the form of free fatty acids, which impair taste and accelerate oxidative damage, and purifying it from precipitated phospholipids, aromatics and pigments that give specific organoleptic properties to oils and fats. Typically, refining consists of the following stages:

- hydration

- neutralisation (often combined with hydration)

- bleaching

- freezing

- deodorisation

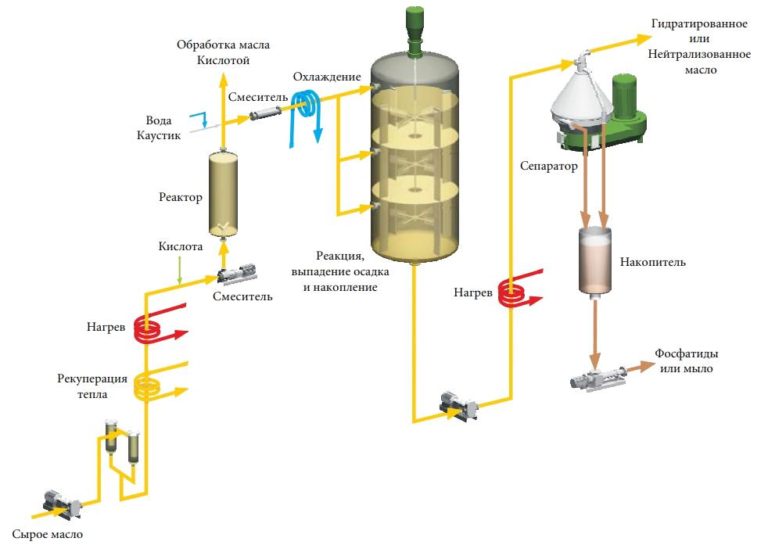

In this article, we will discuss some of the mixing processes that take place in the hydration section, namely the mixing of oil with water and acids. To remove phosphatides and hydrophilic substances, hot steam condensate is usually used in one case and citric or phosphoric acid in the other. The task of these components is to initiate chemical reactions that make it possible to extract phosphatides from the source oil.

One of the most important aspects is the process of feeding acid or water into the oil. Indag Maschinenbau GMBH (Germany) has been manufacturing dynamic mixers for various applications and industries for more than half a century. The company was founded in 1953 in Borsfleet in northern Germany, not far from Hamburg. Over the years, Indag has grown into an international player in the mechanical engineering market and today 70% products are exported to more than 65 countries around the world.

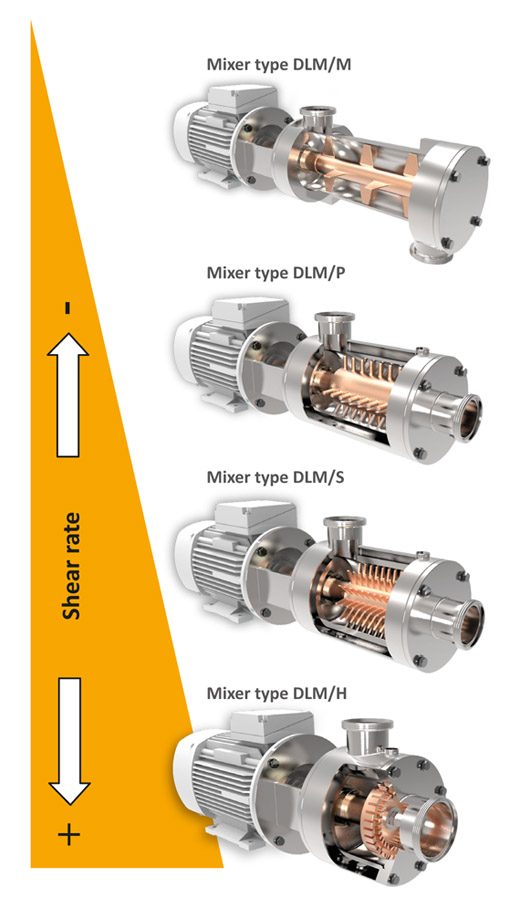

Indag's mixing solutions are continuously operating machines where one or more components are mechanically impacted and mixed. The conceptual range (shown in the figure) is graded in terms of shear force, i.e. from gentle mixing to intense homogenisation. Depending on the process requirements, a mixer with the appropriate level of shear force is selected.

Dynamic mixers with high shear forces are used in oil-acid mixing processes. A high shear force is required for the most efficient introduction of acid into the oil. The DLM/H series of rotor-stator units has been developed for just such applications. Passing through the working teeth and openings of the mixer's working bodies, the acid is broken down into small particles and evenly distributed in the oil. The smaller the particle size, the larger the contact area, and thus the faster the reaction speed.

The high shear force in Indag mixers is achieved by a small precision gap of 300-500 microns between the rotor and stator. The use of this type of machine guarantees:

- Reducing the amount of reagent (acid) used, which means reducing the cost of the final product;

- Improving the quality of the final product, as much less reagent is used to achieve a given product quality.

The DLM/H mixers are available in both team and monoblock versions, covering a wide range of pressure and throughput operating points. By the way, Indag machines do not create any differential pressure after themselves, which is very convenient.

Mixers with high shear forces are not suitable for mixing oil with hot water, as intensive mixing of oil and water leads to the formation of an emulsion. As a rule, after this operation, the mixture is sent to a separator to separate the precipitated phosphatides. The emulsion makes it much more difficult to separate the fractions. That is why Indag offers mixers with medium and low shear forces for this process - the DLM/S and DLM/M series, respectively. These machines allow for efficient mixing of the two fractions without the application of intense shear forces. As a rule, these mixers are quite quiet, and the use of a frequency converter will allow you to adjust the rotation speed and find the most optimal value for the best result.

Indag equipment is chosen not only for its high efficiency, but also for its reliability. Indag has been manufacturing inline mixing equipment for over 60 years and has a wealth of experience with an excellent reputation as a traditional, reliable German company. Indag Maschinenbau is ready to provide not only a standard solution, but also individual developments for your process needs.

Steiner-Ukraine is an authorised partner of Indag Maschinenbau in Ukraine. For more information about this equipment, please contact our technical specialists. We will be happy to advise you and provide the best solution.