Упаковка метизної продукції – це дуже трудомісткий і складний процес, так як у більшості випадків виробники металопродукції висувають найжорсткіші вимоги до обладнання. Це часті переходи з упаковки одного виду продукції на інший, від одного формату до іншого. Це і робота в дві, а то і в три зміни, причому завжди з максимальною продуктивністю. фармацевтико-косметологічного до різних підрозділів, наприклад метизного, пластикового, а також сектору формування кріпильних та інших наборів.

Види обладнання

За призначенням обладнання Imanpack можна розділити на наступні види:

• для пакування цвяхів та різної кріпильної продукції;

• для пакування різної негабаритної металопродукції;

• для пакування запасних частин;

• для пакування електродів;

• для пакування підшипників;

• для формування наборів деталей та кріплення (для складання меблів, наприклад).

Склад обладнання

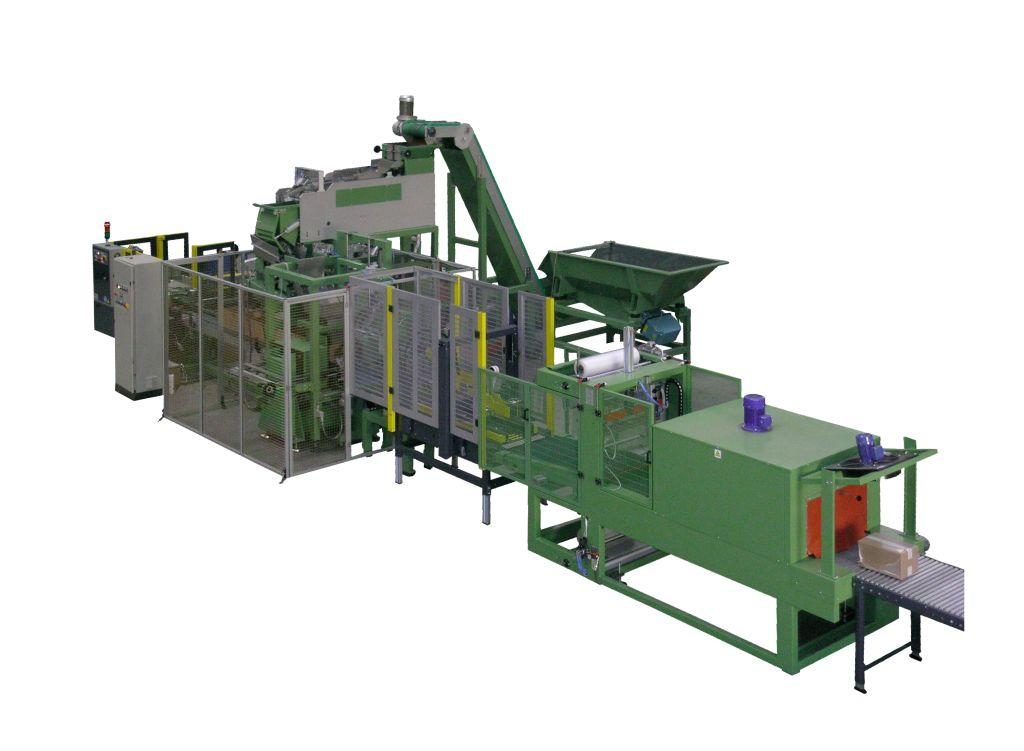

Маючи у своєму прейскуранті велику гаму обладнання, призначеного для продукції різної типології, Imanpack може поставляти комплектні автоматизовані лінії для розфасовки і упаковки кріплення – «під ключ», або ж надавати можливість модернізації та нарощування вже існуючого обладнання.

Для цього випускається ряд різних функціональних пристроїв:

• Вагові електронні дозатори – 14 моделей для задоволення різних вимог при упаковці металопродукції з урахуванням типорозміру продукту, діапазону ваг при розфасовуванні, продуктивності і багатьох інших факторів.

• Високоспеціалізовані засоби подачі продукції: підйомники – перекидачі, вібраційні завантажувальні бункери, транспортерні стрічки, валкові транспортери та інше обладнання, необхідне для реалізації повністю автоматичної лінії.

• Комплекс обладнання для підготовки та завершення процесу упаковки продукції в картонні коробки: це автоматичні формувачі коробок, пристрої закриття клапанів картонних коробок, що дозволяють здійснити автоматичний переход від одного формату до іншого.

• Системи магнітного орієнтування продукції в упаковці (наприклад: цвяхи, шурупи) в пакеті та в коробці.

• Вертикальне обладнання для пакування продукції в поліетиленові пакети. Компанія Imanpack однією з перших почала використовувати технологію упаковки метизної продукції в пакети з можливістю її орієнтування.

• Спеціальні засоби механізації для подачі пластмасових контейнерів типу KLT, широко використовуваних в автомобільної промисловості.

• Автоматичні системи подачі для виробничих ліній термообробки кріплення.

• Етикетувальні автомати.

• Палетайзери

Продуктивність обладнання

Як уже було сказано вище, системи швидкого переходу з одного виду продукції на інший, сприяють диверсифікації партій продукції не зменшуючи, при цьому, продуктивності. Крім того, при кожному переході на інший типорозмір, гарантується швидке повернення в початкове положення. Заміна формату проводиться протягом кількох хвилин, а запуск обладнання за новою програмою здійснюється без порожніх або дефектних прогонів. можуть забезпечити швидкість роботи обладнання до 60 упаковок за хвилину.

Переваги обладнання Imanpack

• Надійність: обладнання спроектоване для стабільної роботи і тривалої роботи в різних виробничих умовах.

• Простота обслуговування: обладнання може обслуговуватися технічним персоналом різного рівня. Процесорний пристрій має достатній обсяг пам’яті для зберігання зберігання численних робочих програм, що забезпечує швидке регулювання машини при переході на інше виробниче завдання.

• Точність: вагові електронні дозатори працюють з максимальною точністю ±1 шт. при різних межах зважування. Електронна апаратура забезпечує мінімальну похибку у вазі: 0,5 г при робочому циклі 15-20 доз на хвилину.

Модулі відліку із застосуванням системи нульового дефекту забезпечують 100% точність відліку. Устаткування Imanpack поставляється в десятки країн світу, включаючи Росію, Україну, Казахстан, Латвію. Крім того, компанія є ексклюзивним постачальником пакувального обладнання для багатьох провідних світових виробників у різних галузях промисловості, наприклад IKEA (виробництво меблів) та SKF (підшипники).

Для отримання більш детальної інформації про обладнання Imanpack звертайтесь до офіційного представника та партнера в Україні компанії «Штайнер-Україна»