Condensed milk with sugar is one of the most popular products among consumers and confectionery manufacturers. It is added to tea and coffee and used to make various dessert creams. Thanks to its affordable price, condensed milk is one of the most sought-after ingredients in the confectionery industry. Many people remember when condensed milk was produced in the Soviet Union and packaged in tin cans. And to this day, tin cans have retained their leading position as one of the most reliable and easy-to-handle types of packaging.

In this article, we would like to focus on the packaging of condensed milk in cans and how it is further processed.

Today, the market of equipment suppliers has a wide range of offers that can meet the needs of a condensed milk producer. However, not everyone is able to achieve the intended goal, namely to supply high-quality and reliable equipment at a reasonable price. This is what makes the Italian company ZACMI stand out from the crowd of equipment manufacturers. Let's try to understand the advantages and distinctive features of ZACMI equipment together.

The packaging line can be divided into two zones: "dry" and "wet". In the wet zone, containers are processed, and in the dry zone, they are labelled and packaged. To improve production hygiene, ZACMI experts recommend separating these zones into separate rooms adjacent to each other. That is, it is desirable that the equipment in direct contact with the product is located in an area of the production facility that is isolated from all residual equipment.

So let's take a closer look at the production processes of the wet zone. Once in the warehouse, the can goes through several stages of heat treatment with hot air, steam or flame. This procedure is used to remove harmful microorganisms from the surface of the can. The treated cans enter the filling unit via a closed conveyor, into which purified air is pumped. The gravity filling unit is a rotary carousel-type machine with volumetric piston dispensers.

Following ZACMI's many years of experience, the lid is treated before sunset using either UV radiation or hot air. Both systems have repeatedly proven their effectiveness, so ZACMI relies on the customer's wishes when choosing one of the above systems.

As we have already mentioned, the jar is transferred from the filling unit to the closing unit. Both machines have a common drive, which allows the jars to be transferred gently, without product splashes, to the closure unit, which is a carousel-type machine with closure heads. With a seemingly standard design of the closure unit, which is common to many manufacturers, ZACMI has managed to find a twist in the stability of the quality of the closure seam, which is one of the fundamental criteria when choosing equipment. The essence of the know-how lies in the fact that during the rolling process, the controller under which the rolling unit operates monitors the dynamic force of each rolling roller applied to the seam of the can. Thus, at the end of the process, the automation already knows how evenly and efficiently each can has been rolled. The rejected cans are pushed out of the line after rolling and are displayed in the unit's statistical data collection and evaluation system. All equipment operates under PLC control in automatic mode. The "dry" zone of the filling line is equipped by ZACMI at the customer's request. Here, as they say, "to taste and colour..." there are many different options. From labellers (whether linear or carousel machines, preference for hot or cold glue, etc.) to packers (shrink wrappers with the ability to form corrugated trays and packaging in cardboard boxes) and palletisers. For more than 60 years of its existence, ZACMI has perfectly mastered the principles of cost optimisation in the design of complete filling lines. So, let's sum up the results. The main distinctive features and advantages of ZACMI equipment.

High durability and reliability

- Stainless steel base containing actuators and cylinder lifting mechanism immersed in an oil reservoir

- Lifting mechanisms made of AISI 304 stainless steel, cylinders made of hardened steel (440C)

- Stainless steel and material hygiene filling valves designed to meet the different characteristics of the packaged product

- Plate and chain type container feed conveyor with synchronisation screw and ratchet for feeding containers made of non-toxic, wear-resistant PVC

- Thick-walled ring container of the filling unit made entirely of stainless steel

- Synchronous operation of the rolling machine with the filling unit

- Electrical control panel with IP 55 protection class

- Controlling machine functions via PLC

- Security systems in accordance with existing European standards

Hygiene

- All parts in contact with the product are made of stainless steel and hygienic material

- All equipment is suitable for washing in the SIP system

- Stationary external foaming systems for filling, rolling and conveyor units

Thanks to the use of innovative developments and technologies in the production of equipment, ZACMI guarantees excellent quality of the final product that meets the highest international standards.

Condensed milk produced in the USSR was packaged in tin cans with blue paper labels. This image was so constant from decade to decade that even now this design is still used as a kind of "brand". At the same time, there are variations of boiled condensed milk that also use the original packaging design, but are coloured brown (the colour of boiled condensed milk). Everyone knows that to produce boiled condensed milk, or toffee, packaged condensed milk must be boiled. In industrial environments, pressure vessels - autoclaves - are used for boiling. The same autoclaves are used to sterilise concentrated milk, which is then poured into tin cans in a similar way to the process described above for packing condensed milk with sugar.

It is a well-known fact that the quality and competitiveness of a product directly depend on the quality of the equipment used to produce it. In this part of the article, we would like to talk about sterilisation systems that will allow canned food producers to significantly improve the quality and efficiency of their production, while reducing their dependence on electricity costs.

Despite the seeming simplicity of the end product, the production of high-quality canned food is a complex and high-tech process. The production of canned food imposes strict requirements on the technical equipment of the enterprise, and the equipment of Soviet production complexes cannot produce competitive products, efficiently heat treat food, or reduce the time of the processing cycle itself.

Spoilage of products of plant and animal origin is caused by the vital activity of microorganisms and the action of enzymes that make up their composition. Currently, to create the necessary optimal conditions for preserving vegetables and fruits, meat, fish or condensed milk, heat sterilisation and pasteurisation are of practical importance, as they almost completely destroy microorganisms and their spores. For most Ukrainian producers of canned milk, the costs of heat and electricity are among the main expenses and are becoming comparable to the costs of raw materials. Therefore, the task of switching canning companies to energy-saving technologies, including horizontal autoclaves, is very urgent today.

Canned food manufacturers who take the quality of their products seriously have long realised that traditional equipment is not capable of producing canned food of the required quality with guaranteed high shelf life. Therefore, they decided to develop a new segment of equipment for them - horizontal autoclaves. Horizontal autoclaves use the following technologies for heat treatment of pre-packaged products:

- Steam & Air (steam treatment)

- Air Steam Spray (ferry treatment + spray)

- Full Water (full immersion)

- Shower Cascading.

Global experience shows that the water cascade technology implemented by STERIFLOW is the most efficient from a technological point of view and the least expensive in terms of its maintenance, taking into account the entire life cycle. The world's leading and increasingly Ukrainian producers of canned dairy, meat and fish products have been convinced of this for a long time.

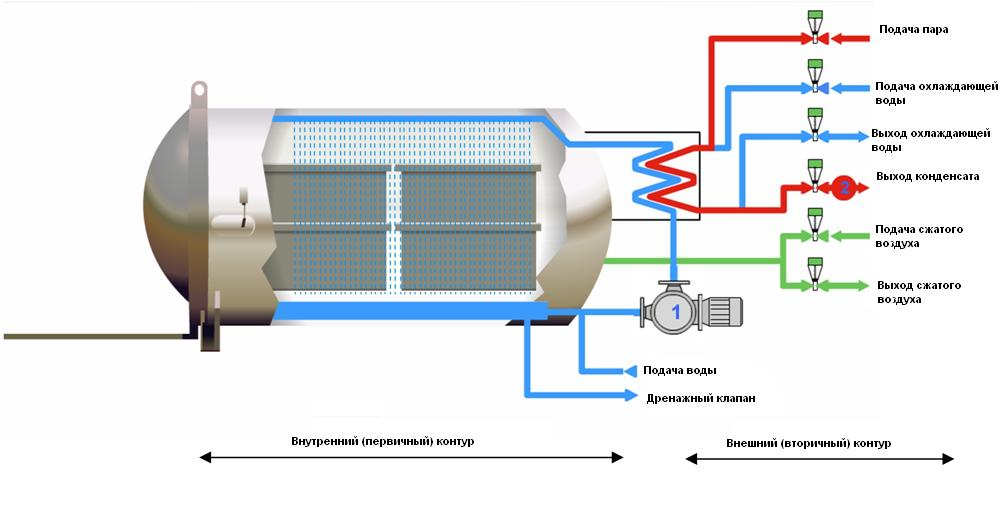

The principle of operation of the STERIFLOW autoclave:

The bottom of the chamber is filled with 100 to 400 litres of potable process water (the volume of water depends on the capacity of the plant). The circulation pump delivers the water to the heat exchanger, where it is heated by steam to the set temperature, and then evenly irrigates the product using the distribution system.

The process water collects at the bottom of the chamber, is fed into the heat exchanger, cooled and used to cool the sterilised product. The water used in the heat exchanger does not need to be treated and can be of any quality, as it circulates in a closed loop and does not come into contact with the sterilised product. At the end of the process, uncontaminated water can be discharged directly into the environment.

The pressure in the chamber is temperature independent and is controlled by automatic injection or suction of compressed air during all phases of the process cycle.

Technically, the water cascade system is implemented as follows:

The pipe system consists of two circuits: an internal circuit and an external circuit. The internal circuit consists of a circulation pump connected to the heating side of a Barriquand PLATULAR plate heat exchanger. The outer circuit consists of inlet and outlet pipework connected to the nozzles on the heating side of the heat exchanger. Water circulates in the autoclave chamber as a heat transfer medium. In the process of heating, the circulating water passes through the inner circuit of the heat exchanger and is heated by steam, which enters the outer circuit of the heat exchanger. To ensure a uniform temperature field throughout the chamber, the circulating water is used to irrigate the product evenly through the water distributor. During the cooling stage, cooling water is supplied to the external heat exchanger circuit to remove heat from the circulating water. The cooling water does not come into contact with the product packaging and can be of any quality, including service water or recycled water.

The patented PLATULAR plate heat exchanger, fully welded from stainless steel without gaskets, ensures high heat transfer efficiency, compactness and low metal consumption of heat exchange equipment, and guarantees long-term trouble-free operation - up to 30 years!

The design of the Barriquand STERIFLOW autoclave eliminates the risk of thermal shock for glass containers and ensures sterilisation of products in various packaging: glass, metal and even easily breakable plastic; safety and energy saving in the event of a power outage, which is typical in areas where canned food producers are predominantly located.

The STERIFLOW is primarily used as a steriliser-cooler, but it can also be used as a pasteuriser-cooler or a cooker-cooler. This versatility is of great practical importance, as it allows the range of products to be expanded without the need for additional equipment.

The energy consumption of STERIFLOW is lower than that of other autoclaves, as it uses the patented "water cascade" technology, which means that the products are heated by flowing water, which ensures faster heat transfer. This results in an even temperature distribution, which is important for ensuring long-term storage of canned food with reduced heat treatment time without losing valuable nutrients.

Glass containers and tins provide a long shelf life for many products, but their heavy weight and breakage make them very inconvenient to use and force manufacturers to move towards new materials and technologies. For some products, replacing inconvenient and heavy glass and metal packaging is a must.

The "water cascade" technology under the control of the Barriquand STERIFLOW autoclave's MPI microprocessor controller allows for the mitigation of heat treatment conditions and the use of modern polymeric packaging for food storage, including canned food, makes it possible to sterilise any type of packaging by adjusting temperature and pressure, and increases the safety of autoclave control, which means that not only does it solve the problem of improving product quality, but also provides additional benefits due to the properties of polymeric packaging:

- low weight;

- low cost;

- the ability to create packaging of almost any configuration and size, convenient for transport and storage;

- the possibility of reusing the packaging material after recycling;

- the possibility of combining canning and packaging production processes at one enterprise.

The ease of use of STERIFLOW autoclaves is due not only to the wide range of heat treatments, but also to a number of specific mechanisms to facilitate the work of staff, including the automatic basket loading conveyor inside the autoclave. This device allows you to instantly load a full basket of products into a clearly defined place before the start of the cycle or, on the contrary, unload the finished product from the autoclave. This conveyor significantly saves staff time and effort when working with horizontal autoclaves, especially those with a capacity of 4 to 12 baskets.

To date, more than 3,500 STERIFLOW autoclaves have been installed and are successfully operating in 105 countries. According to statistics, more than 6 billion units of various packaged products are pasteurised and sterilised in these autoclaves every year. In Ukraine and Russia, there are more than 100 Barriquand STERIFLOW autoclaves, many of which were installed during the Soviet Union and have not caused any complaints so far. At one time, the company's customers included the Ministry of Meat and Dairy Industry of the USSR, the Ministry of Fruit and Vegetable Production of the USSR, the Ministry of Fisheries of the USSR and the USSR State Agricultural Committee.