Steiner is an expert in the world of pumps

In this article, we are going to talk about Sydex screw pumps, one of the most well-known and widely used pump groups in the dairy industry.

This short overview may make it easier for you to make an immediate choice in solving your dairy pumping problem.

In addition, Steiner-Ukraine specialists will be happy to advise you and select the right unit for your pumping needs.

Quality first and foremost!

Even in such a difficult time for our country, we all care about product quality, and dairy companies are proving that they are really strong, unbreakable and invincible. Being under fire in different regions, they risk their own lives to respond with dignity to all the changing circumstances and continue their hard work. Of course, the war is having a negative impact on the dairy sector, but our first task today is to help our dairy farms survive!

Steiner-Ukraine has long been one of the leaders in the supply and sale of various stainless steel equipment and integrated solutions for pumping liquids in the dairy industry.

Let's start our article with an introduction to the Italian manufacturer of screw pumps Sydex...

This is one of the most widely used pumps in Ukraine today. It is used to pump almost all products in the food industry. Therefore, the scope of application of the screw pump in the dairy industry is almost unlimited, in particular from pumping viscous, thick, viscous products to low-viscosity liquids. The most popular products that can be transported with a screw pump are yoghurt, sour cream, cream, fruit fillings, processed cheese, whey, condensed milk, etc. The particles in the product are not destroyed, crushed or mixed with the base liquid. The pumped medium is gently and linearly pushed along the screw pair.

Due to their technical features, pumps are manufactured in various configurations, for example, many enterprises use a submersible screw pump. Although this design is rare, it allows solving a large number of tasks.

How the Sydex screw pump works

The main components of screw units are the rotor and stator. The material for the former is usually steel (stainless or hardened), and for the latter - elastomer. Each of them must be as wear-resistant as possible. When the rotor is inserted into the stator, a chain of watertight chambers must be formed. Therefore, their shapes and sizes require perfect precision. As the rotor rotates, it changes the volume of the cavities and forces the contents to move in a spiral from the suction to the discharge port. Meanwhile, a new portion of the liquid that has gone into the pipeline is supplied to replace it. There is no return path for the liquid, as the design provides a closed space. Thanks to this, the supply of substances occurs regularly, smoothly and without sharp fluctuations. This characteristic has made screw pumps very common in dosing and proportional flow processes.

Design features

- The screw is driven by an electric motor and does not come into contact with the inner surface of the pump casing as it turns. This reduces friction to a minimum, resulting in a long service life.

- The medium moves in the pump with a constant axial flow direction. This ensures that the pump delivers a steady flow of product without pulsations. The pump has low noise pollution. Since the moving parts of the pump have low inertia, the starting torque and vibration are low.

- The pump has a high suction capacity.

- To ensure the safe operation of the pump, motor and pipework, all high-capacity pumps are equipped with safety valves. In the event that the operating pressure exceeds the maximum pressure for which the system is designed, the safety valve will operate and the excess product will be directed back into the suction chamber via the bypass.

Sydex pump versions

Depending on the requirements of the process, screw pumps are available in a variety of designs, including:

K series. The most common general industrial series, high efficiency and many material options.

H-series. A series that is specially adapted to the needs of the food industry, where hygiene and sanitary performance are very important.

Can be adapted for SIP washing, meets FDA and EHEDG requirements.

E-series. The pumps of this series have a special design. They are designed for vertical installation and pumping products from containers and barrels.

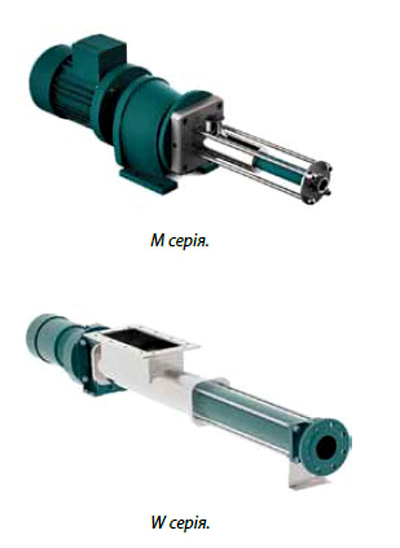

M-Series. The special series for precise dosing and proportional feeding.

It can operate in the speed range from 0 to 1000 rpm with an integrated frequency converter.

W-series. Designed for particularly viscous products containing large amounts of suspended solids or non-flowing products.

For such tasks, a special storage hopper is provided on the suction side of the pump, as well as a feed screw that will forcefully capture and feed the product into the rotor and stator chamber.

Sydex pumps have the following advantages:

- hygienic design;

- the ability to work in a closed loop;

- easy washing and cleaning;

- easy disassembly and dismantling;

- Stable delivery pressure regardless of rotor speed;

- work with viscous products;

- gentle pumping of sensitive and delicate products.

We offer a wide range of pumping equipment of various types, have solutions for complex processes and products, and select Sydex pumps to meet all the requirements of each customer. That is why today, screw pumps are the choice of both large dairy processing plants and small and medium-sized local industries.

Together we are strong! We remain optimistic and are ready to rebuild, recover and positively influence product quality together with the dairy industry.

As quality has always been and remains the greatest value of every product, production in the realities of war should not be spoilt, but rather be automated as much as possible and meet the highest quality standards. These are the standards that everyone involved in the creation and production of food should follow. The current disaster should only serve as an impetus for a new stage in the development of dairy production in Ukraine, and producers should be able to resume operations and meet all consumer needs in the near future.