The homogenisation of many liquid and pasty foods is now becoming one of the main types of processing in mass production. This process ensures that the product does not stratify during long-term storage or transport.

Other types of processing, as a rule, do not produce the same quality effect. Homogenisation is the process of crushing fat globules in milk into smaller ones during dispersion and their subsequent uniform distribution throughout the finished product. It is used in the production of pasteurised and sterilised milk, dairy drinks, cream, yoghurt, dairy desserts, reconstituted and condensed milk, baby food, formula and milk mixtures.

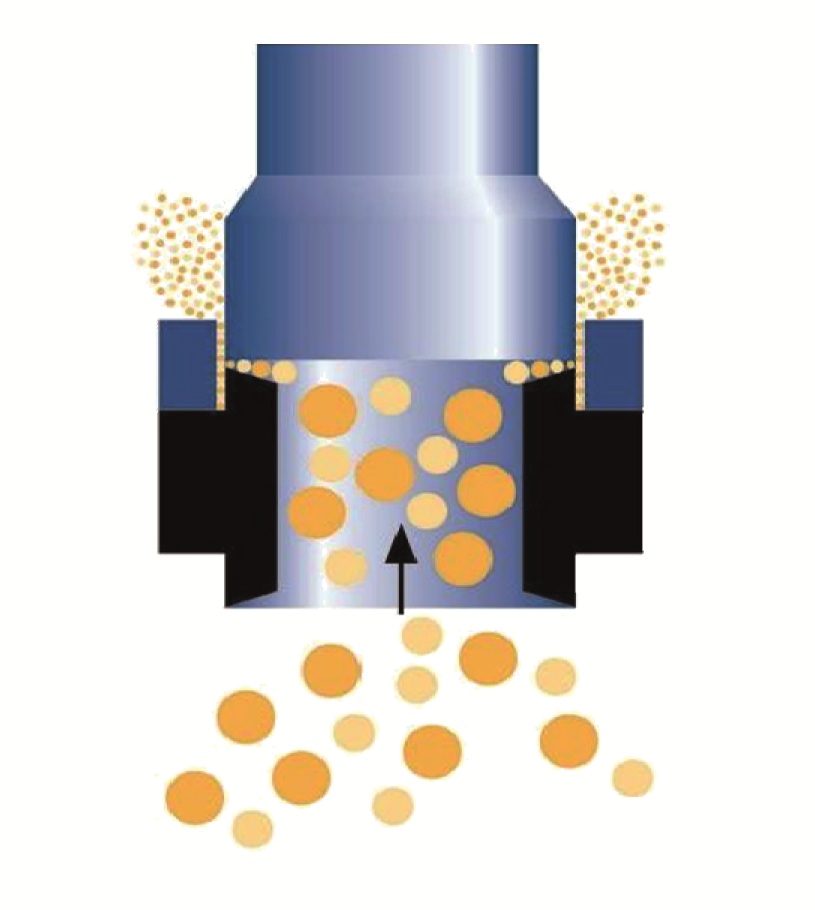

Figure 1. The homogeniser

Bertoli homogenisers

A high-pressure homogeniser is an apparatus consisting of a high-pressure positive displacement plunger pump and a homogenisation valve. Since the effect of the homogenisation valve is based on the pressure drop as the product passes through the outlet channel, it is necessary to increase the valve diameter to maintain the minimum width of the passage channel. However, at the same time, the homogenisation force increases (with an increase in area) and the valve becomes large, heavy and difficult to operate.

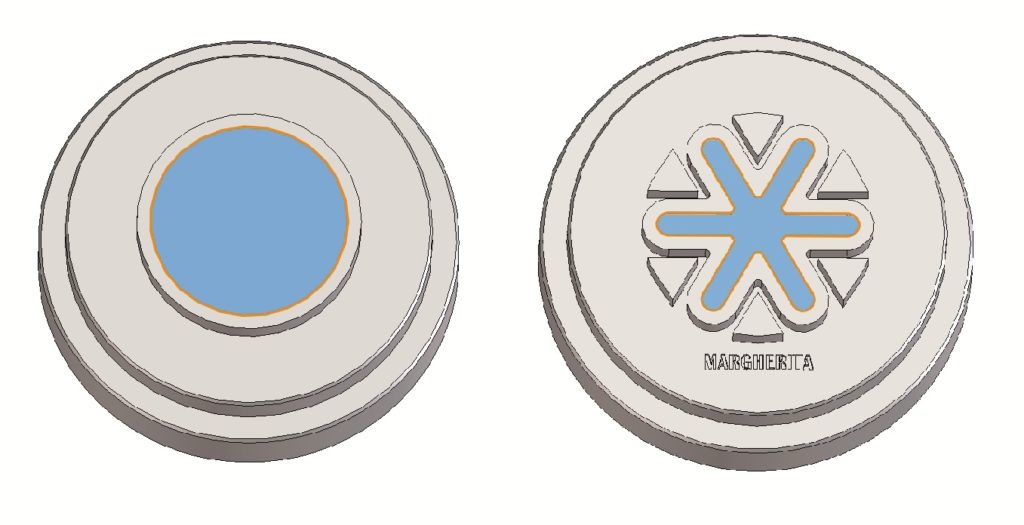

Figure 2. Bertoli high efficiency valve

For more than 40 years, the Italian company Bertoli has been producing homogenisers of various models and configurations with a capacity of 10-60 thousand litres per hour and a homogenisation pressure of 1-2. The company carries out research work on the selection of materials, improvement of homogenisation technology and energy saving, as well as analysis of flow dynamics and structural changes in contacting materials. Moreover, Bertoli specialists have developed and patented a high-efficiency valve that increases the perimeter of the flow channel (Italian).

Fig. 3. Homogeniser passage head: a - radial classical design; b - MARGHERITA.

How it works

The product enters the compression head and is compressed by a plunger pump. A homogenisation valve is installed at the outlet of the compression head. By adjusting the distance between the homogenisation valve and the impact head, the required pressure is created. The adjustment is carried out using a hydropneumatic system mounted on the homogenisation unit. The working height of the homogenisation valve is approximately 0.1 mm (100 sizes of a fat particle in milk); the product flow rate through the homogenisation valve varies from 100-400 m/s, with a transit time of 10-15 microseconds. During this time, all the pressure transferred to the liquid is converted into kinetic energy: less than 1% of the required energy is used by the homogenisation process. The remaining energy is transformed into heat and therefore the product is heated as it passes through the homogenisation valve. For example, for milk, the product temperature increases by 1°C for every 40 bar of homogenisation pressure.

How it works

The product enters the compression head and is compressed by a plunger pump. A homogenisation valve is installed at the outlet of the compression head. By adjusting the distance between the homogenisation valve and the impact head, the required pressure is created.

The adjustment is carried out by means of a hydropneumatic system installed on the homogenisation unit. The working height of the homogenisation valve is approximately 0.1 mm (100 times the size of a fat particle in milk); the product flow rate through the homogenisation valve varies from 100-400 m/s, with a transit time of 10-15 microseconds. During this time, all the pressure transmitted to the liquid is converted into kinetic energy: less than 1% of the required energy is used by the homogenisation process. The remaining energy is transformed into heat and therefore the product is heated as it passes through the homogenisation valve. For example, for milk, the product temperature increases by 1°C for every 40 bar of homogenisation pressure.

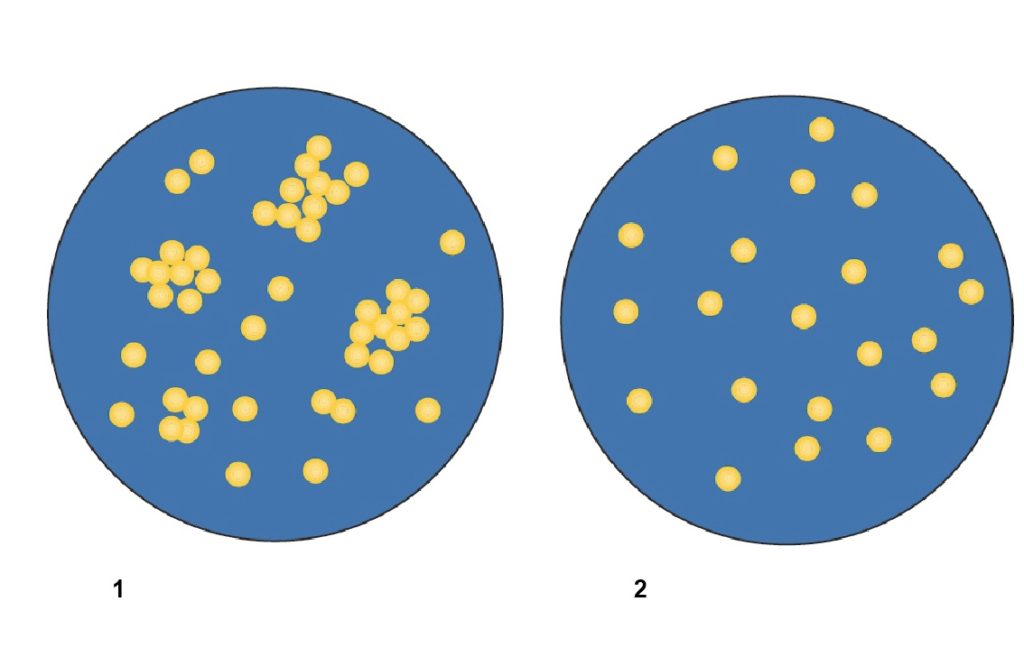

Figure 4. Particle distribution after the 1st and 2nd stages of homogenisation

Application

The benefits of homogenisation are well known in the dairy industry. It allows for a more stable product with a longer shelf life, improved product flavour, reduced additives and a clearer product composition. pastes, juices, ketchups, mayonnaise and many other products. During the homogenisation process, the selection of suitable materials and wearing components is crucial to ensure a good level of machine reliability and reduce operating and maintenance costs. Bertoli can provide materials specially designed to meet the most demanding technical standards, such as alloys and synthesised materials, corrosion and wear resistant materials, and ceramic products.