Що ми знаємо про двогвинтові насоси?

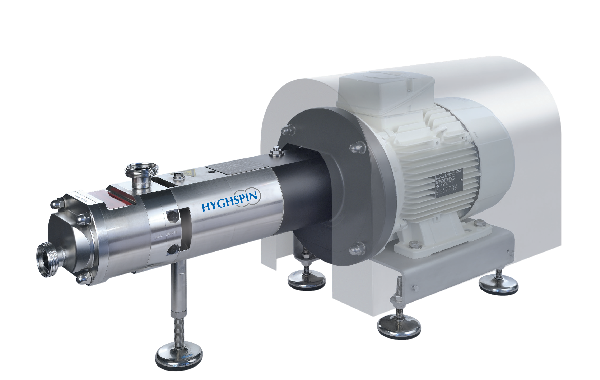

Двогвинтовий насос – це насос об’ємного типу, принцип дії якого ґрунтується на обертанні двох гвинтів. При попаданні в робочу камеру продукт переміщується лінійно між витками шнеків. Така технологія перекачування знайшла собі застосування в нафтогазовій промисловості ще на початку XX століття – двогвинтові насоси широко використовуються для перекачування мультифазних середовищ. У харчовій галузі ці агрегати почали фігурувати відносно нещодавно. Одним із тих, хто почав виробляти та акцентувати увагу на ефективності використання таких насосів у харчовій галузі, є компанія Jung Process Systems (Німеччина). Ключові особливості їхньої лінійки двогвинтових насосів Hyghspin ми зараз розберемо.

Hygienic design

— Насоси сертифіковані відповідно до EHEDG,

— Гвинти не стикаються один з одним і мають незалежний привід – це виключає тертя та попадання металевих частинок у продукт.

— Усі контактні поверхні відполіровані та мають шорсткість 0,8 мкм (опціонально можна зробити до 0,4 мкм).

— Відсутність «мертвих зон», адаптований до CIP та SIP очищення.

Бережне перекачування продукту та подача без пульсацій

Двогвинтовий насос, як ніякий інший забезпечує дбайливе перекачування делікатних продуктів. Якщо говорити про жорсткі включення, то залежно від конфігурації гвинтів, Hyghspin може працювати зі шматочками до 45 мм без пошкоджень. Щодо впливу на текстуру самого продукту — тут жодних проблем немає. При перекачуванні делікатних продуктів (shear sensitive products), на них виявляється мінімальний гідравлічний зсув. Все ґрунтується на лінійному переміщенні – при проходженні через насос продукт не змінює своєї траєкторії і весь час знаходиться у просторі між витками шнеків. Якщо взяти, наприклад, кулачковий насос, то в ньому продукт переміщається за рахунок обертання роторів і при цьому кілька разів змінює напрямок руху. На високих обертах насос може збивати та нести згубний вплив на продукти з чутливою структурою. Насоси Hyghspin набагато гнучкіші у цьому плані.

Рішення 2 в 1: один насос для продукту та СІП

Це перевага, яку не має жоден з об’ємних насосів. Виконання та принцип перекачування дозволяє насосам Hyghspin працювати на швидкостях обертання гвинтів до 3600 об/хв. Ця особливість забезпечує гнучкість у продуктивності та створюваному тиску. Розглянемо приклад для насоса Hyghspin90:

Основний режим – подача йогурту, 25 м3/год, 3 бар; в’язкість продукту 1500 сПз; швидкість 563 об/хв.

Режим СІП – перекачування СІП розчину (каустик), 50 м3/год, 3 бар; в’язкість 1 сПз; швидкість 1765 об/хв.

З в’язким продуктом насос працює на невисоких швидкостях 563 об/хв, а СІП розчині на 1765 об/хв. Режим миття зазвичай потребує більш високих продуктивностей. З кулачковим або гвинтовим насосом потрібно робити байпас, оскільки пропускна здатність через них обмежена. На високих оборотах вони працювати не можуть, а ставити насос більше заради СІП економічно не вигідно. Використання одного насоса Hyghspin дозволяє уникнути байпасу і скоротити кількість трубопроводів. Це робить всю систему більш ефективною та гігієнічною. Для роботи на різних швидкостях насоси Hyghspin оснащуються спеціальними електродвигунами конфігурації VSD (variable speed drive) із регулюванням частоти від 5 до 130 Гц.

Якісний та ефективний продукт

Компанія «Jung Process Systems» спеціалізується на виробництві двогвинтових насосів, тому якості Hyghspin приділяється 100% уваги. Усі операції з виробництва деталей та збирання насосів здійснюються на новітньому машинобудівному устаткуванні. Лінійка насосів є 4 типорозмірами, які покривають діапазон продуктивностей від 0,03 м3/год до 300 м3/год. Необхідну комбінацію витрати та тиску забезпечує певна конфігурація гвинтів та швидкості обертання, яка підбирається індивідуально під запит клієнта. Також хотілося б відзначити досить непогану самовсмоктувальну здатність (NPSHr до 0,5 м) та високий тиск на виході (до 35 бар). Діапазон в’язкості продуктів, що перекачуються від 1 до 1 000 000 сПз, температура від -10С до 130С.

Таким чином, двогвинтові насоси Hyghspin – це якісний продукт, який відповідає всім сучасним вимогам та стандартам. З його допомогою підприємства можуть вирішити низку складних технологічних завдань та зробити своє виробництво найефективнішим.

Для підбору насоса Ви можете звернутися до наших спеціалістів за тел. 044-390-73-38