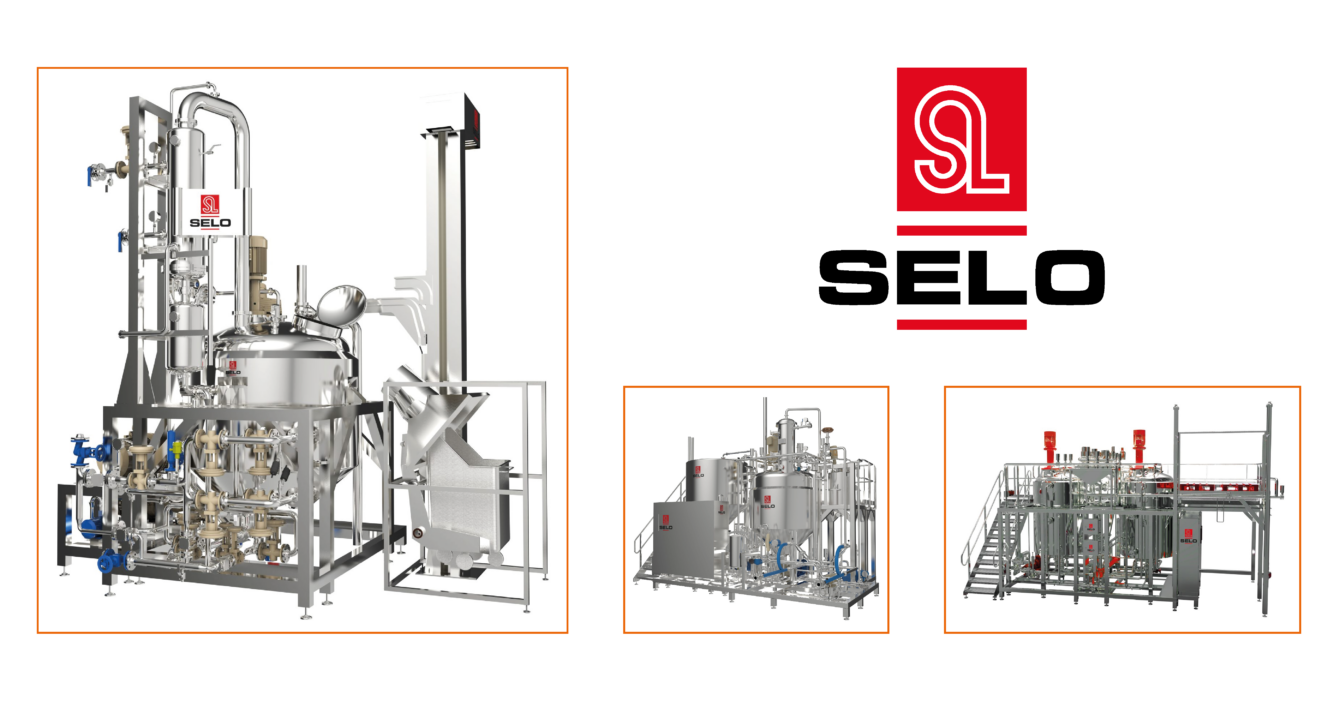

Industrial production of sauces, mayonnaise, ketchup, and other liquid food products requires high quality, stable structure, precise recipe control, and production efficiency. Selo — a leading European supplier of technologies for processing high-viscosity products — offers fully automated lines for industrial sauce production that combine hygienic design, flexible process settings, and fast recipe changeovers to meet current production needs.

What is the Selo sauce production line and what is it for?

The Selo sauce production line is a complex of technological machines and modules designed to convert raw materials into finished food sauces, ketchups and mayonnaises in large volumes. It supports flexibility in the production of various flavours and types of sauces, including tomato, mild vegetable, pizza sauces, pasta sauces, and special dressings.

The systems are designed for:

- Consistently high product quality without loss of taste, colour or texture;

- Quick changes to recipes and settings between batches;

- Automation of key stages of production — from mixing to cooling.

The main technological stages in sauce production

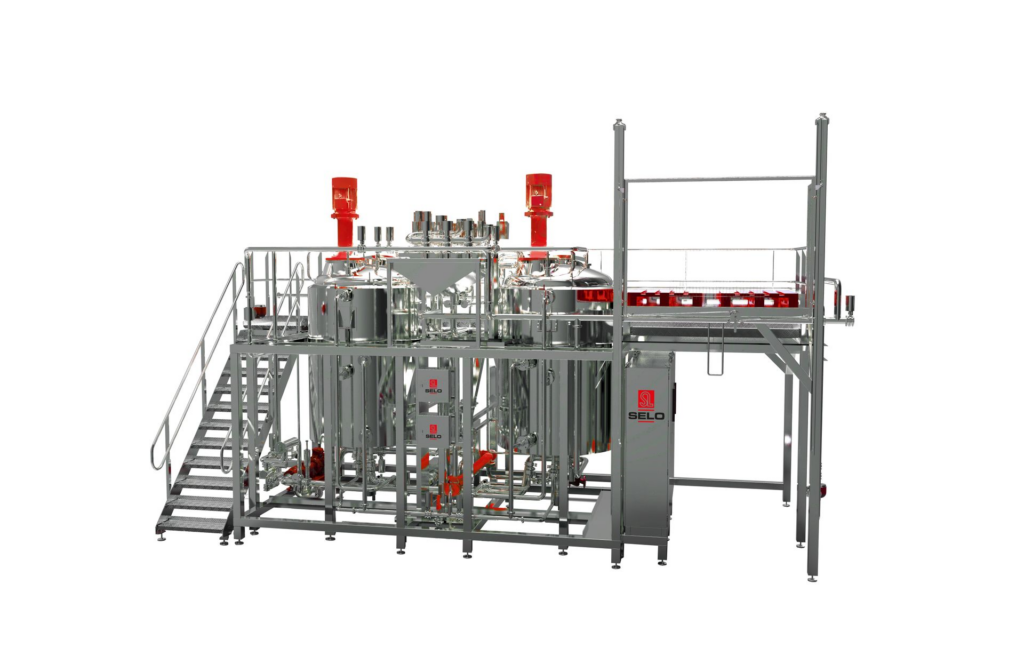

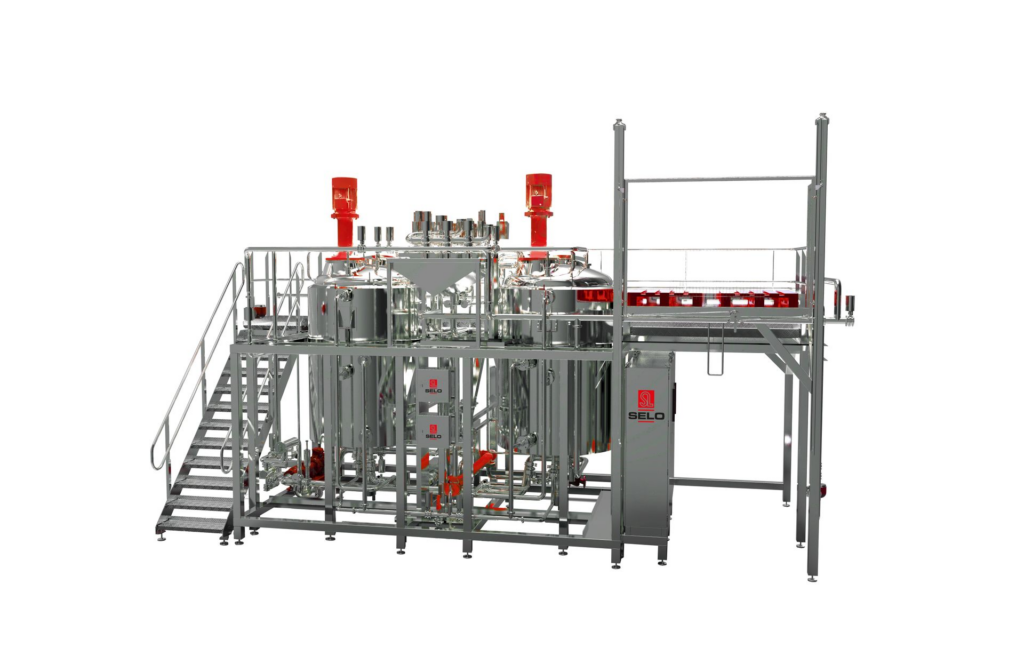

Selo industrial lines for sauces include the following key processes:

Preparation of ingredients and mixing

Ensures uniform mixing of ingredients (vegetable puree, tomatoes, vinegar, oil, spices).

This is critical for the consistency of the sauce's flavour and texture.

Temperature control

Thermal processing of sauces (cooking, pasteurization) is carried out with automatic parameter control, ensuring food safety and consistent product quality.

Hygienic and automatic pumping

The systems are designed to work with a hydraulic line and can be integrated with homogenisers, direct steam injection and cooling systems, which increases recipe stability.

Preparation for packaging

The finished sauce can be supplied for packaging into jars, bottles, doy-packs, or other formats while maintaining a high level of hygiene.

Advantages of Selo sauce production lines

Flexibility in recipe production

The lines allow you to quickly change recipes and switch between sauce types, such as ketchup, tomato, vegetable or special sauces, without significant downtime.

High stability of product quality

Process automation ensures uniform texture, taste, and color of each sauce batch, which is essential for meeting consumer expectations and reducing waste.

Increased efficiency and safety

The equipment design complies with high hygienic standards and allows for reducing the human factor in the production process, thereby increasing operational efficiency and product safety.

Automation and parameter control

Selo systems can be integrated with modern PLC control systems for automatic control of temperature, pressure, and mixing speed, reducing the risk of errors and making production predictable.

What sauces can be produced on Selo lines?

The lines cover a wide range of sauces, including:

- Tomato sauces (pasta, spaghetti, pizza);

- Meat and vegetable sauces with pieces of ingredients;

- Hot or cold sauces;

- Special dressings and marinades.

These lines are not limited to sauces only and can be adapted for soups, dressings, mayonnaise, and other liquid food products.

Technological options and modules

Selo offers additional technical components and integrated solutions to increase productivity:

- Homogenisers – for the required product consistency;

- Direct steam injection systems – for temperature control and pasteurisation quality;

- Vacuum cooling – to reduce processing time;

- CIP (Clean-in-Place) modules – for automatic cleaning of equipment in accordance with EHEDG standards.

Advantages for the manufacturer: what exactly does the Selo line offer?

Increased productivity

Automated lines allow for a significant increase in sauce production volumes with less time and resources.

Reduced operating costs

Less manual labour, less waste and optimised recipe changes make the process cost-effective.

Guaranteed product quality

Precise control of production parameters allows us to comply with food standards and market demands.

Sauce production lines from Selo are modern, automated technologies that enable manufacturers to increase productivity, improve product quality and consistency, respond quickly to recipe changes, and comply with strict food standards.