ContiCooker is an innovative solution for cooking wet pet food by scansteel foodtech. The system optimizes the processes of cooking, pasteurization, and sterilization, ensuring consistent product quality and preservation of the nutritional properties of ingredients.

What is ContiCooker and what is it used for?

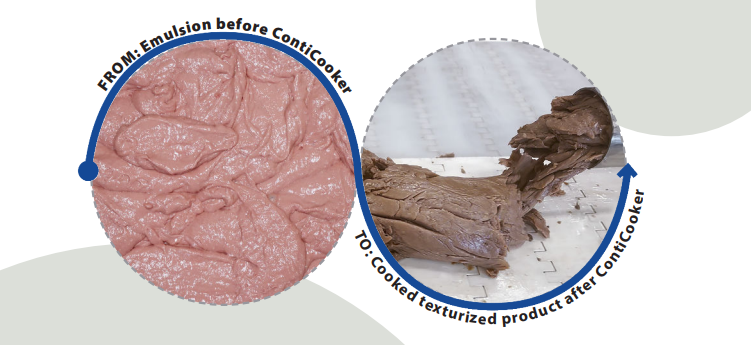

ContiCooker is a continuous feed processing system with the ability to cook, sterilise, pasteurise or caramelise. It is suitable for wet and paste-like feeds, as well as for emulsions and other complex mixtures that require precise temperature and time control.

Thanks to the continuous processing method, the ContiCooker is capable of handling large volumes of feed mixtures, increasing production efficiency and reducing processing time.

Main areas of application:

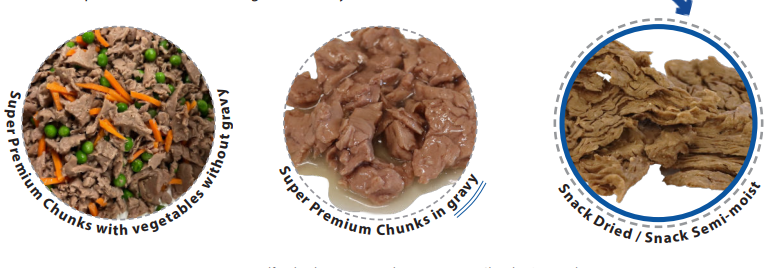

- Wet food for dogs and cats

- Advanced recipes for super premium feeds

- Protein-plant mixtures

- Preparation of feed with a high content of meat and offal

Advantages of ContiCooker for manufacturers

- Continuous cooking process

ContiCooker provides a continuous processing cycle from initial heat treatment to the final product. This continuous process significantly reduces the time required for loading and unloading mixtures, which greatly increases productivity without compromising quality. - Improved feed quality

Thanks to precise temperature control and moisture content, the system ensures consistent feed quality that meets technological requirements. This is important for manufacturers who want to preserve vitamins and trace elements and achieve a uniform texture in animal feed. - Energy efficiency and resource savings

Choosing the ContiCooker allows you to optimise energy consumption thanks to precise control of temperature and pressure during the cooking process. The system ensures increased processing efficiency by minimising heat loss, which reduces overall production costs. - Hygienic design

The equipment is designed to meet high hygiene requirements, which is particularly important for animal feed production. ContiCooker is easy to clean, has sealed areas to prevent contamination and convenient access to all parts for regular cleaning.

ContiCooker technical specifications

ContiCooker is designed for continuous cooking and comes in several versions to meet the needs of different types of feed:

- Temperature control: The system allows you to precisely adjust the temperature to ensure optimal conditions for cooking food with different ingredients.

- Cooling system: Cooling option to slow down the process in order to avoid overheating the feed and preserve its structure and nutritional properties.

- Time adjustment: Ability to precisely control processing time to achieve the desired results for a specific feed formulation.

- Productivity: From 1,000 to 10,000 kg/hour depending on the type of raw material and line capacity.

How to choose a ContiCooker for your production?

When choosing a ContiCooker system, it is important to consider several key parameters:

- Type of feed: Wet and paste-like feeds, emulsions, and feeds with a high meat content require different processing modes. Choose a model with the necessary set of functions for your recipe.

- Productivity: Determine how much feed you plan to produce per hour in order to select a model with the appropriate capacity.

- Technical requirements for the process: If you require additional cooling or precise temperature control, it is important to select the appropriate configuration.

Continuous cooking system – how ContiCooker works

ContiCooker operates on the basis of a continuous processing process, which means:

- Cooking and sterilising the feed immediately after mixing.

- Automatic temperature and pressure control to achieve the perfect product consistency.

- Low energy costs thanks to the use of innovative heat exchange technologies.

Conclusion: why choose ContiCooker

If your business is involved in the production of wet pet food or super premium products for pet food, ContiCooker by scansteel foodtech will be the optimal choice. With high efficiency, precise process control, and ease of maintenance, this system allows you to produce high-quality products with minimal energy and time costs.

For the right model for your production needs, contact Steiner Ukraine — we will help you choose the best solution for your business.