In industries such as food production, beverage manufacturing, and pharmaceuticals, the demand for hygienic, efficient, and reliable equipment is critical. HYGHSPIN twin screw pumps from Jung Process Systems set new standards by combining advanced technology with exceptional versatility, delivering unparalleled performance even under challenging operating conditions.

What Are Twin Screw Pumps?

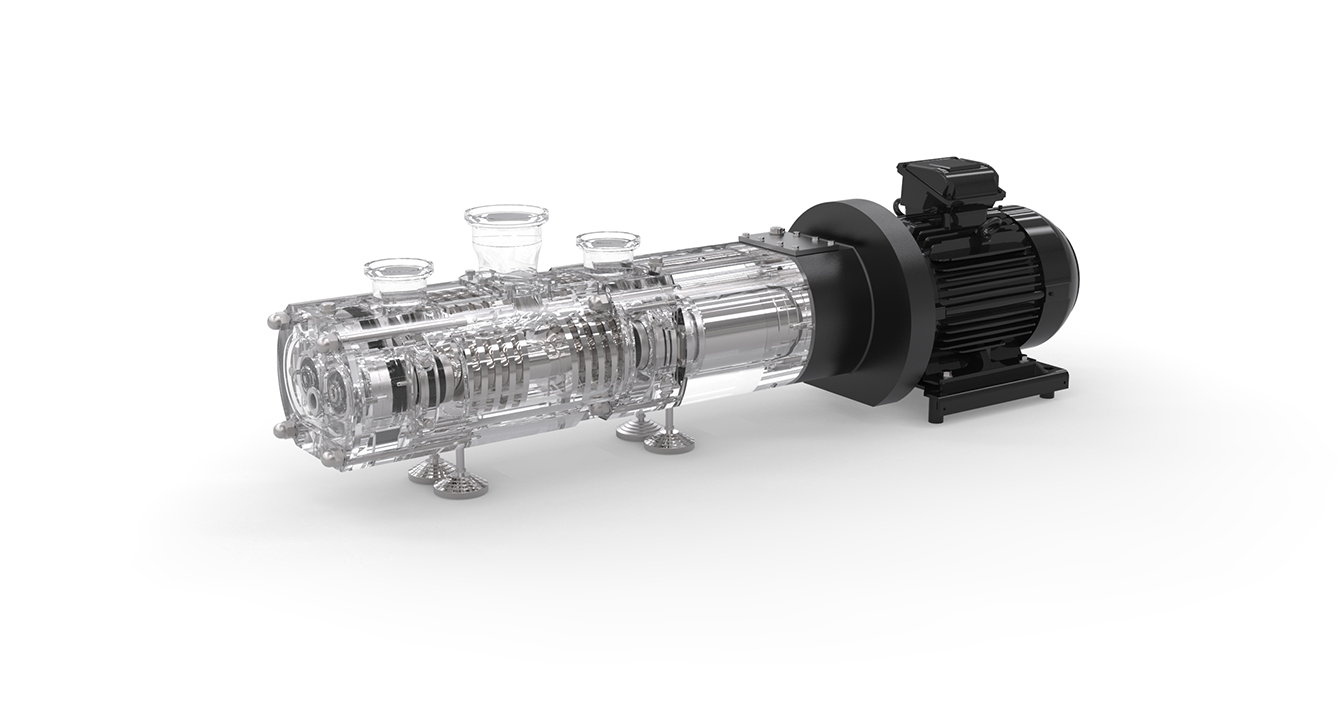

Twin screw pumps are designed to transport precise volumes of product based on the speed and pitch of the screws, ensuring smooth and gentle flow.

- The pump features left and right feed screws.

- During operation, the screws create sealed chambers that move the product axially in a consistent, controlled flow.

This design minimizes product damage, making it ideal for handling sensitive or highly viscous materials.

Applications of HYGHSPIN Twin Screw Pumps

Applications of HYGHSPIN Twin Screw Pumps

- Food production

- Pet food manufacturing

- Cosmetics

- Beverage production

- Pharmaceuticals

- Chemical industry

Since 2009, Jung Process Systems, a global leader in OEM pump manufacturing, has specialized in hygienic twin screw pumps made from stainless steel. The HYGHSPIN series offers dual functionality, combining product transport and Clean-in-Place (CIP) cleaning in a single system. This eliminates the need for additional pumps, reducing complexity and costs.

These pumps can handle products of virtually any consistency and are available in block design or free shaft-end configurations.

7 Reasons to Choose HYGHSPIN Twin Screw Pumps

- Unmatched Flexibility

HYGHSPIN pumps handle a wide range of flow rates, volumes, and viscosities, making them highly versatile. They work seamlessly with various media, serving as both transport and continuous cleaning (CIP) pumps. Their rotors operate at extended speeds of up to 4,000 rpm. - Gentle Product Handling

The nearly pulsation-free operation and excellent suction capability make these pumps ideal for sensitive products. The axial product flow minimizes separation or damage, while the sealed chambers ensure uniform filling and unloading. - Hygienic Excellence

HYGHSPIN pumps deliver exceptional cleanliness without the need for bypass systems. Their design allows mechanical seals to be rinsed in the main flow, enhancing cleanability. The system is cavity-free, self-cleaning, and supports steam-in-place (SIP) sterilization. Certifications like EHEDG, 3-A (USA), and ATEX emphasize compliance with stringent hygiene standards. - Simplified System Design

By eliminating the need for bypasses or external CIP pumps, HYGHSPIN reduces system layout complexity, cutting investment, maintenance, and operational costs. - High Wear Resistance

By eliminating the need for bypasses or external CIP pumps, HYGHSPIN reduces system layout complexity, cutting investment, maintenance, and operational costs.Non-contact transport elements prevent product damage from abrasive particles. With reinforced components, the pumps can handle abrasive media while maintaining a long service life and high reliability. - Corrosion Resistance and Easy Maintenance

Fully made of stainless steel, HYGHSPIN pumps resist corrosion and meet high standards for external hygiene. Maintenance is simplified with features like guide bolts for assembly and in-place adjustment of feed screws without dismantling the motor or gearbox. - Compact and Space-Saving Design

Available in block or free shaft-end configurations, these pumps save space and enhance operational safety. The block design ensures precision machining from a single piece of stainless steel, reducing misalignment risks and simplifying cleaning.

The HYGHSPIN Advantage

With HYGHSPIN twin screw pumps, industries benefit from increased efficiency, reduced costs, and superior product integrity.

Steiner is proud to offer advanced solutions that address real-world challenges and enable businesses to optimize their operations.