Vojta – Mixing plants

Vojta s.r.o. offers equipment for the production of ice cream, including mixing plants of the MIX HTST and MIX BATCH series.

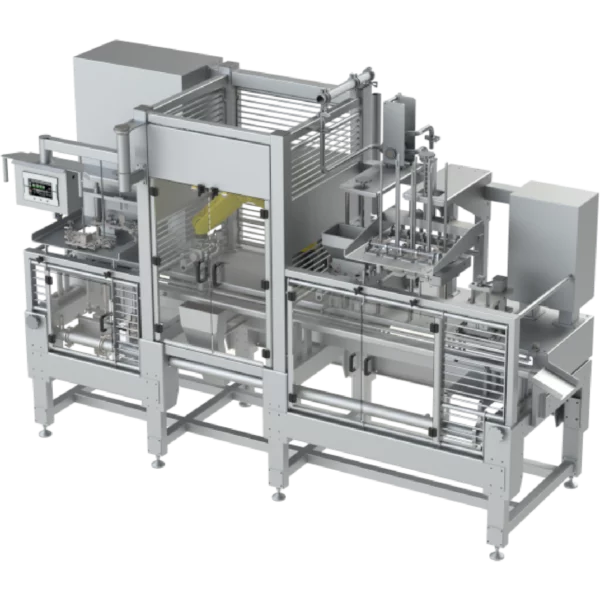

MIX HTST

The MIX HTST is a continuous closed-cycle unit for instant pasteurization, homogenization and cooling of ice cream mixtures with a capacity of 300 to 5000 l/h. The HTST system is energy efficient and easy to operate. The unit has a compact and hygienic stainless steel design that minimizes space requirements and provides easy access to all components for inspection and maintenance.

Features of MIX HTST:

- Two mixing tanks with two-speed agitators and temperature display

- Filter for the mixture

- Centrifugal pump for supplying the mixture to the balancing tank

- Balancing tank with float regulator

- Centrifugal pump for feeding the mixture to the heat exchanger

- Plate heat exchanger with 4/5 sections

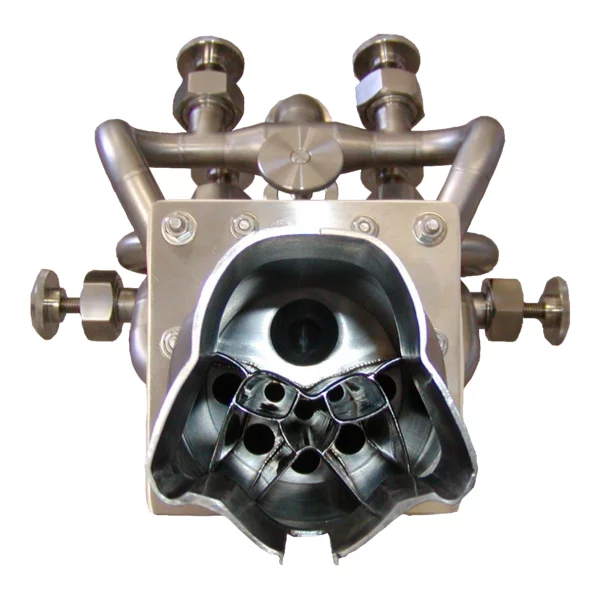

- Homogenizer with a working pressure of 180-250 bar, single or two-stage

- Tubular holding block

- Control panel with electronics, temperature display and liter counter

- Liter counter for measuring the amount of water added to the mixing tank according to the recipe

- Hot water boiler for the pasteurization section of the heat exchanger (heating can be done by electricity, gas or steam)

- Centrifugal pump for supplying hot water to the heat exchanger

Additional equipment:

- Disolver

- Special design for mixtures with high solids content

- Hot water storage tank for improved pasteurization stability

- Additional heat exchanger for the first batch

- SCADA for exporting data from the plant

- CIP installation

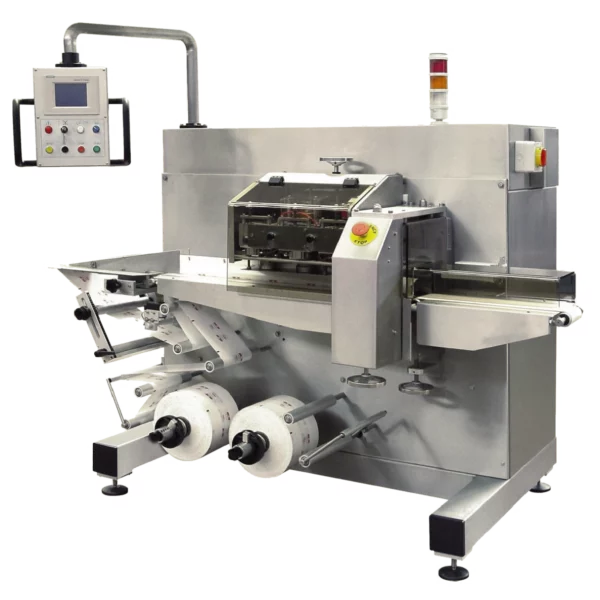

MIX BATCH

The MIX BATCH is a continuous closed-cycle plant for instant pasteurization, homogenization and cooling of ice cream mixes with a capacity of 150 to 1200 l/h. The unit has a compact and hygienic stainless steel design that minimizes space requirements and provides easy access to all components for inspection and maintenance.

Features of MIX BATCH:

- Two mixing tanks with temperature display

- Filter for the mixture

- Centrifugal pump for feeding the mixture to the heat exchanger

- Plate heat exchanger with 2 sections

- Homogenizer with a working pressure of 180-250 bar, single or two-stage

- Control panel with electronics and PLC operator interface with process visualization

- Liter counter for measuring the amount of water or milk added to the pasteurization tank according to the recipe

- Hot water boiler for pasteurization tanks (heating can be done by electricity, gas or steam)

- Centrifugal pump for hot water supply to the pasteurization tanks