Vojta – Filling

Vojta s.r.o. specializes in the development, production and maintenance of equipment for industrial ice cream production. Their products include several series of automatic and semi-automatic machines for filling various types of ice cream. Below is a structured description of the main series of equipment:

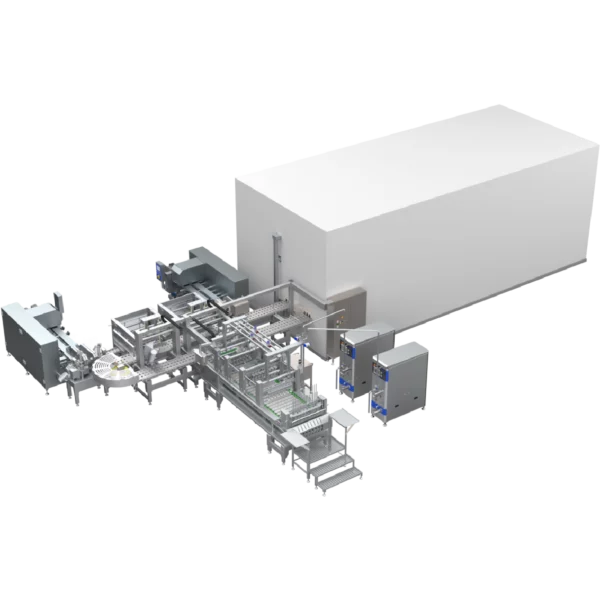

1. LF series

- Purpose: Automatic linear machines for filling cups and cones.

- Features:

- Sturdy stainless steel frame with adjustable feet.

- Operator panel with 9-inch touch screen.

- Saving machine settings as recipes.

- Several stations for filling and dosing dry ingredients.

- Heat sealing stations.

- Productivity: Up to 18,000 units per hour.

- Additional options:

- High-pressure positive displacement pumps.

- Various filling and decorating stations.

- Vertical extrusion cutting stations.

- Robotic transfer of finished products to the hardening tunnel.

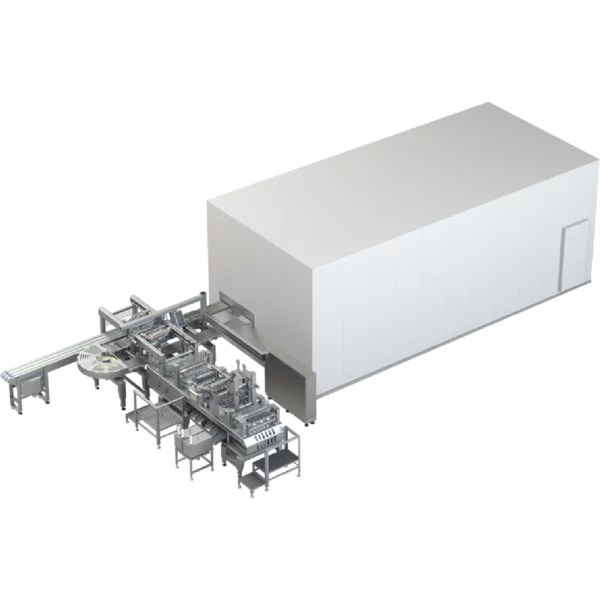

2. ALF series

- Purpose: Automatic linear machines for filling cups and cones.

- Features: Similar to the LF series, with an emphasis on flexibility and ease of maintenance.

- Productivity: Up to 18,000 units per hour.

- Additional options: Similar to the LF series.

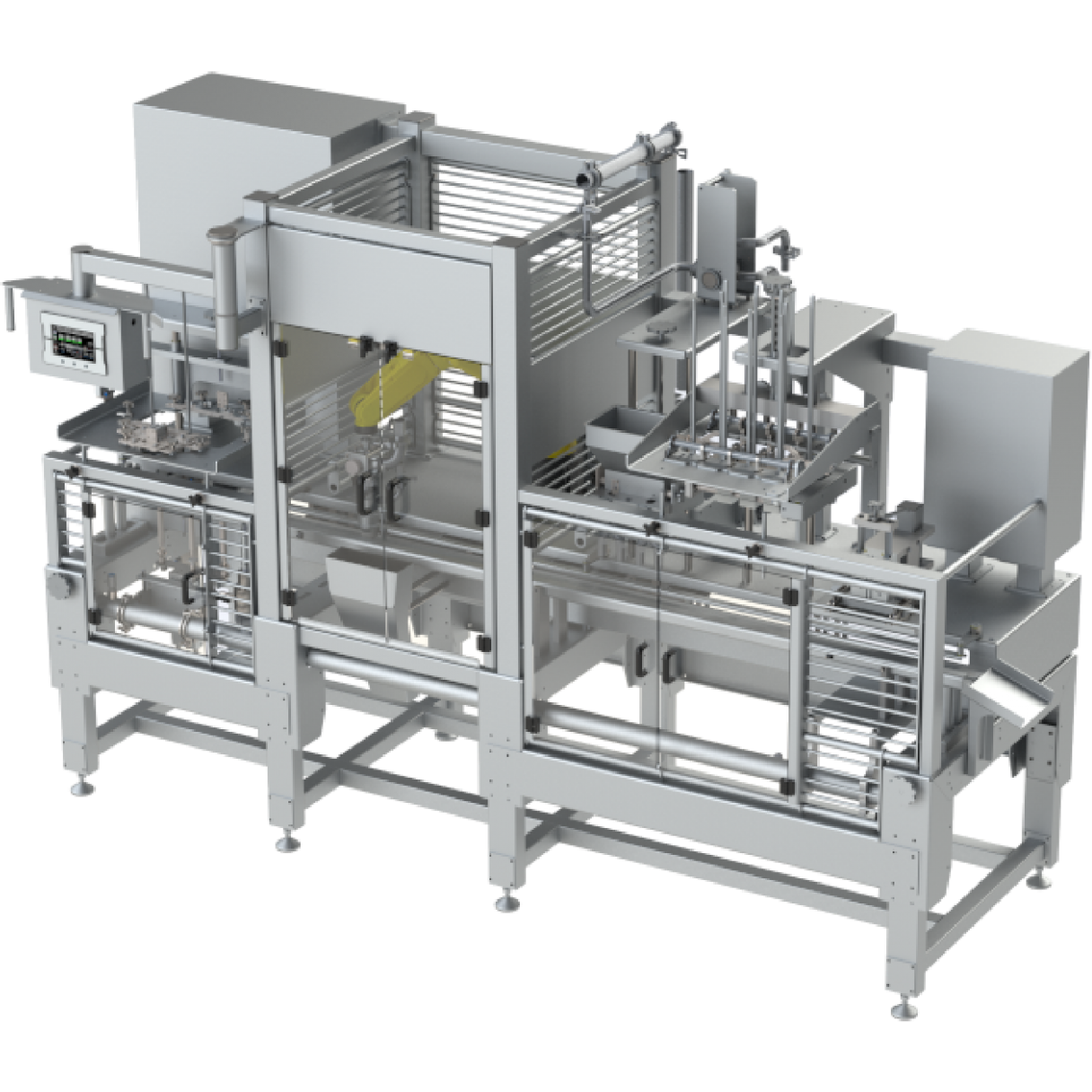

3. WT series

- Purpose: Automatic machines with high flexibility for the production of various products: cups, containers, large volumes and cakes.

- Features:

- Storing product settings in the PLC for easy switching between products.

- Open design for easy access and maintenance.

- Highly accurate dosing and a variety of filling stations.

- Productivity:

- Cakes: up to 1,500 units per hour.

- Cups: up to 6,000 units per hour.

- Family packs: up to 3,000 units per hour.

- Food packaging: up to 1,500 units per hour.

- Additional options:

- 3D robotic filling station.

- Pumps for special ingredients.

- Robotic transfer to the hardening tunnel.

4. SF series

- Purpose: Simple and reliable machines with high flexibility for the production of cups, containers, large volumes and cakes.

- Features:

- Compact design with low maintenance costs.

- Highly accurate dosing and the ability to dose dry ingredients.

- Vertical cutting stations for extrusion and heat sealing.

- Productivity:

- Cups: up to 3,000 units per hour.

- Family packs: up to 1,500 units per hour.

- Food packaging: up to 800 units per hour.

- Additional options: Similar to the WT series.

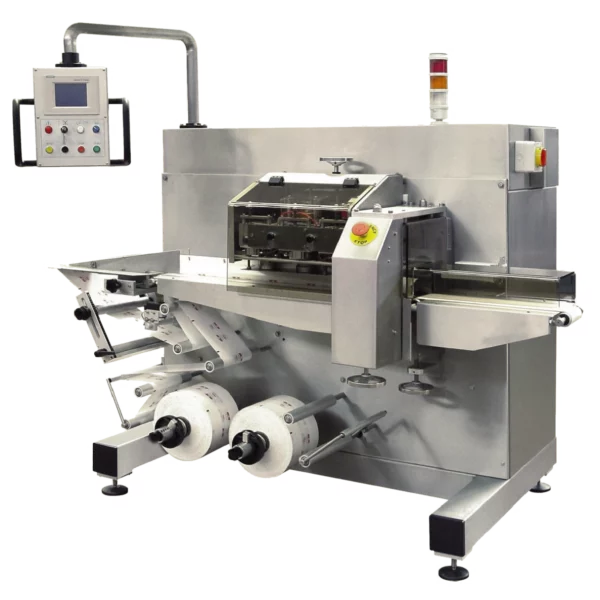

5. SFM series

- Purpose: Semi-automatic machines for filling ice cream with or without inclusions into “family” containers of various shapes or for decorated cakes.

- Features:

- Completely made of stainless steel and anodized aluminum.

- Electro-pneumatic operation with easy control.

- Technical parameters:

- Dimensions: 2000x710x930 mm.

- Power consumption: 4 kW.

- Compressed air: 6 bar.

- Additional options:

- Dosing units for large inclusions.

- Attachments for different types of decoration.

- Possibility of integration with conveyor systems for process automation.

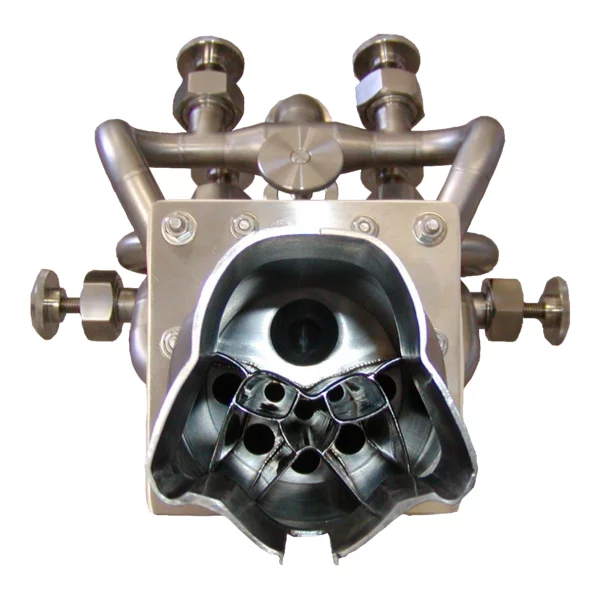

6. BF2 series

- Purpose:

Semi-automatic machines for filling ice cream into large containers or for the production of cakes with the possibility of complex decoration. - Features:

- Stainless steel construction for high durability.

- Volumetric dosing with high accuracy.

- Operator panel for setting process parameters.

- Ability to work with different textures and types of ice cream.

- Technical parameters:

- Compact size for easy placement in the production area.

- Minimal maintenance requirements.

- Operation from compressed air (6 bar).

- Additional options:

- Nozzles for decorating cakes.

- Dispensers for additives (nuts, chocolate chips, fruit pieces).

- Advanced automatic cleaning system.

General advantages of Vojta equipment

- Flexibility: the ability to quickly reconfigure for different types of products.

- Automation: reducing manual labor and increasing process accuracy.

- Hygienic: stainless steel materials and automatic cleaning systems ensure compliance with sanitary standards.

- Integration: the ability to combine with other production lines and hardening tunnels.

- Energy efficiency: low consumption of electricity and compressed air.

Such solutions ensure high productivity and product quality, which allows ice cream producers to optimize their production process and increase their competitiveness in the market.