For modern production, the right choice of pumping equipment is extremely important. After all, it determines the efficiency of the enterprise, the overall quality of the final product, and the stability of all technological stages. But which unit should be selected for specific application conditions and what should be taken into account to avoid unwanted mistakes? Let's talk about all this in more detail.

Types of production pumps - their types and features

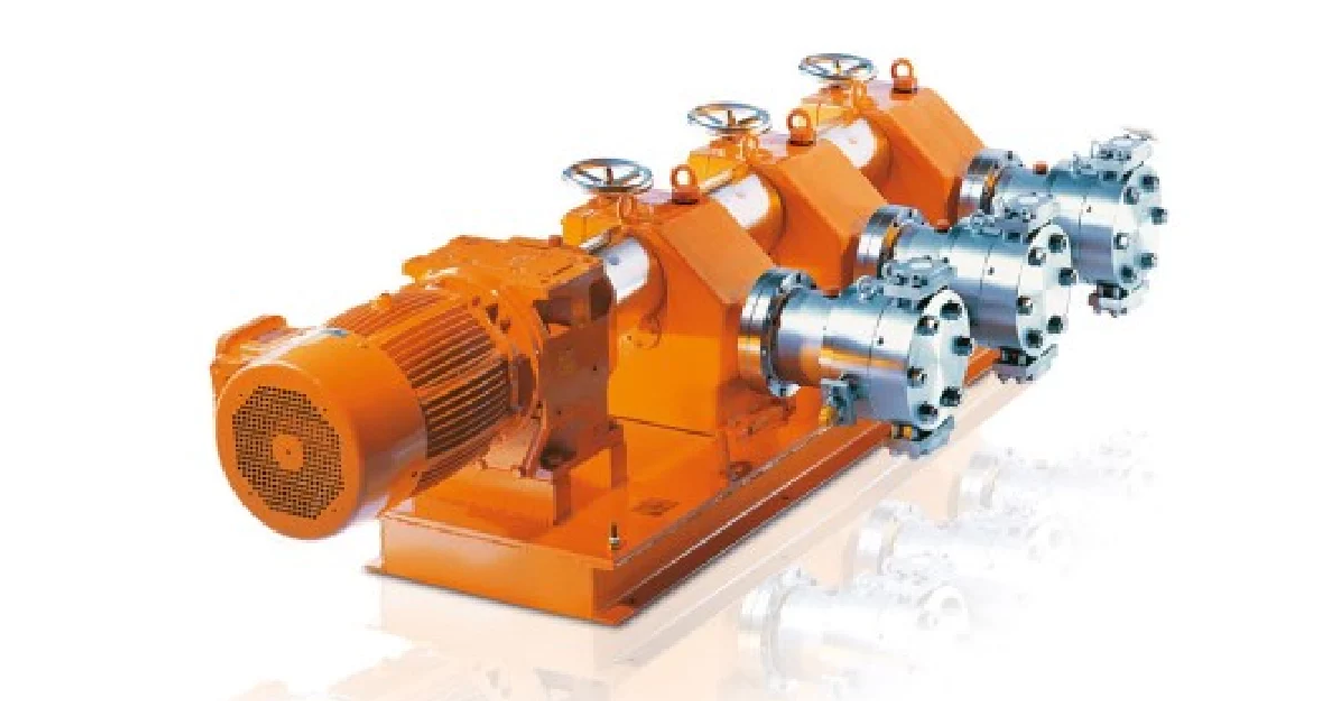

There are four types of pumps used in production: centrifugal, diaphragm, screw and gear. The former are used for pumping low-viscosity liquids, ensuring stable and uniform operation of production lines. Diaphragm pumps are suitable for aggressive and contaminated environments, minimizing the contact of the liquid with moving parts. Screw valves are capable of handling thick and viscous mixtures, while gear valves are used to supply lubricants and other specific liquids.

It should be understood that each of these pumps has its own application. Centrifugal pumps are used in water supply systems and chemical production, while diaphragm pumps are optimal for the pharmaceutical and food industries. Screw pumps are indispensable in the processing of oil products and foodstuffs, and gear pumps are indispensable for lubrication systems and technological processes with continuous and accurate fluid supply. It is only necessary to choose the right equipment, taking into account the conditions and specifics of its application.

The main aspects of the choice - what to look for

When choosing equipment, the first thing to consider is the following:

- Pump performance. Calculate the volume of fluid that needs to be pumped per unit of time to ensure uninterrupted production.

- Compatibility of materials. Ensure that the housing and internal parts of the unit are suitable for the fluid properties and operating conditions.

- Temperature range. Pay attention to the temperature of the working fluid to prevent possible deformation and equipment malfunctions.

- Energy consumption. Evaluate the efficiency of the pump in terms of energy consumption and stability over the production cycle.

- Ease of maintenance. Choose models that are easy to set up, minimizing downtime of production lines during maintenance.

When choosing equipment, you should trust only proven units from a reliable brand that can offer high-quality systems with comprehensive service. After all, this is the only way to guarantee their trouble-free use over a long period of time, saving not only your own time but also money.