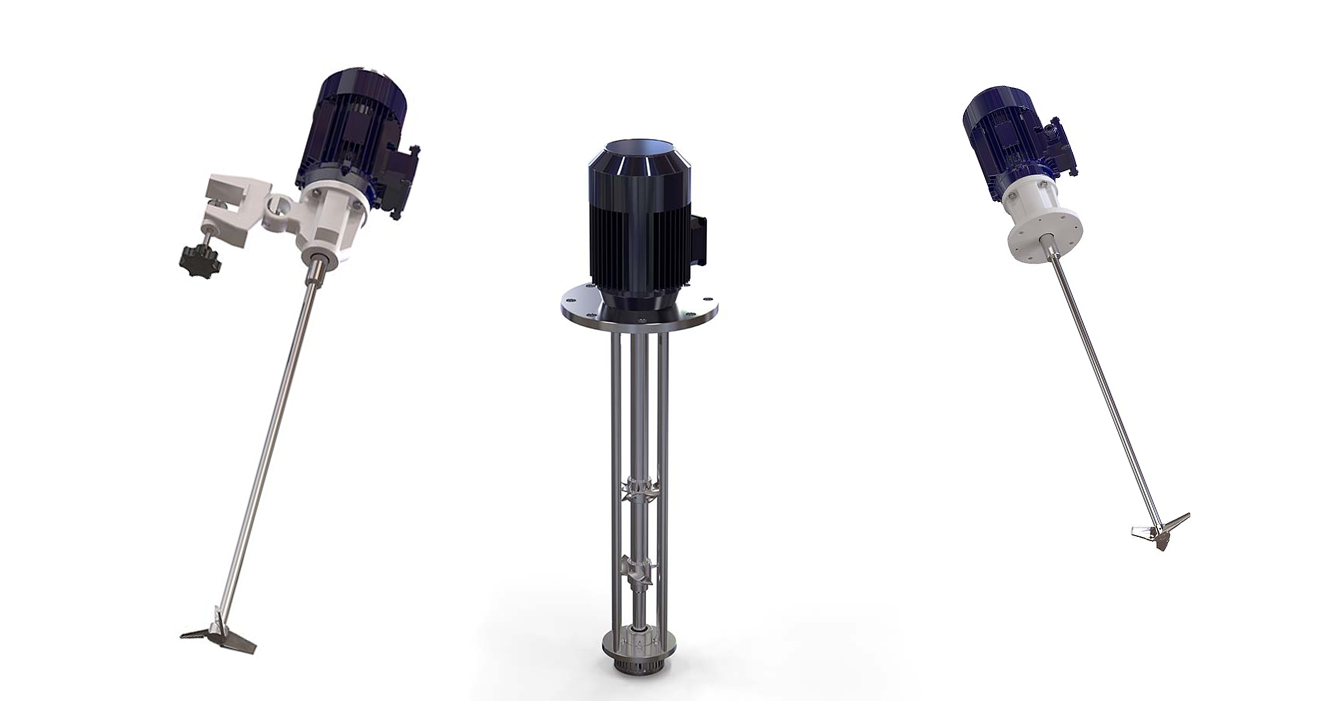

An agitator is a device designed to mix, emulsify, homogenise or disperse liquids and semi-solids. Due to their design and functionality, agitator mixers are widely used in various industries.

The agitator-mixer consists of an electric motor, a drive and a mixing element (blade, propeller, turbine) that rotates inside the tank. The movement of the mixing element creates a hydrodynamic flow that ensures uniform mixing of the components.

The process can take place through various mechanisms:

- Mechanical mixing: Blades or propellers create turbulent flow in the liquid.

- Dispersion: The particles are divided into smaller fractions.

- Emulsification: Mixing two phases, such as water and oil, to form an emulsion.

- Homogenisation: Reducing the particle size to produce a homogeneous product.

Areas of application

- Food industry:

- Mixing sauces, creams, yoghurts, syrups.

- Preparation of emulsions (e.g. mayonnaise).

- Pharmaceuticals:

- Homogenisation of creams, ointments, suspensions.

- Preparation of sterile solutions.

- Cosmetics industry:

- Mixing creams, shampoos, gels.

- Create emulsions and gel-like textures.

- Chemical industry:

- Dispersion of paints, varnishes and adhesives.

- Mixing aggressive and viscous liquids.

- Agriculture:

- Preparation of feed mixtures.

- Dissolving fertilisers and pesticides.

Features of the agitator mixers

- Type of mixing element:

- Paddle stirrers for viscous liquids.

- Turbine agitators for low-viscosity applications.

- Propeller agitators to create a strong flow.

- Materials of execution:

- Stainless steel (AISI 304/316) for food, pharmaceutical and chemical products.

- Corrosion-resistant coatings for use with aggressive substances.

- Type of drive:

- Electric: Ensures high performance and stability.

- Pneumatic: For use in explosive atmospheres.

- Rotation speed:

The adjustable speed allows the agitator to be adapted to different processes (homogenisation, mixing, emulsification). - Possibility of integration:

Some models support automation and integration into production lines.

What is the right mixer for you?

- Process type:

Determine whether the stirrer is used for mixing, emulsifying, dispersing or homogenising. - Fluid characteristics:

- Viscosity: Consider whether the medium is liquid, viscous, or paste-like.

- Sensitivity: Whether the structure of the product needs to be preserved.

- Tank volume:

Choose the model with the right shaft length and power for your tank. - Materials:

Select the material of the body and mixing element depending on the medium (food, aggressive or sterile liquids). - Compatible with CIP/SIP systems:

For pharmaceuticals and food processing, make sure the equipment supports automatic cleaning. - Rotation speed:

Choose a model with adjustable speed if you need to perform different tasks. - Energy consumption:

Consider equipment efficiency to reduce energy costs.