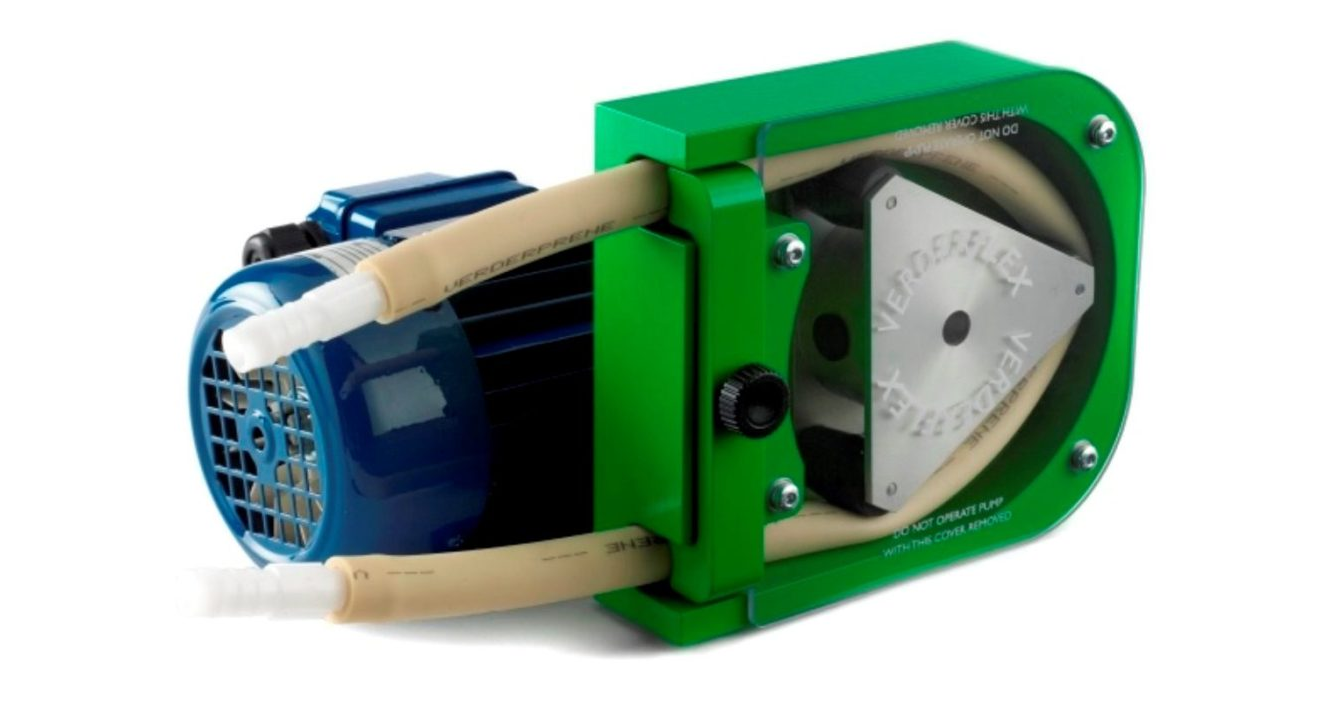

The basis of a peristaltic pump is a flexible hose through which fluid is pumped and rollers or shoes that create compression. The movement of the rollers ensures that the fluid is pumped evenly, like waves pushing water through a narrow channel.

This technology has several key advantages:

- No direct contact between the liquid and the pump.

- Tightness and complete isolation of the liquid from the external environment.

- Capable of handling aggressive, sterile or biologically contaminated liquids.

Application of peristaltic pumps

- Pharmaceutical and biotechnology industry: They are used for sterile dispensing of solutions, transportation of biological materials, cell cultures and reagents.

- Food industry: Suitable for working with syrups, sauces, fruit purees and other liquids sensitive to mechanical stress.

- Chemical industry: Ideal for pumping aggressive liquids such as acids, alkalis and slurries.

- Water treatment and wastewater treatment: They are used for dosing reagents, flocculants, coagulants and disinfectants.

- Medical field: Peristaltic pumps are used in hemodialysis, blood pumping, medical solutions and drugs.

- Laboratories and research: Provide accurate dispensing of small volumes of liquids for analytical and scientific applications.

Features of peristaltic pumps

- No contact with liquids: Thanks to the flexible hose, the liquid does not come into contact with the internal elements of the pump, eliminating the risk of contamination.

- Precise dosage: They provide high accuracy when working with liquids of any viscosity.

- Wide range of hose materials: Hoses are made of various materials (e.g., silicone, PTFE, EPDM), which allows the pump to be adapted to the chemical composition of the pumped liquid.

- The ability to work “dry”: Unlike many other types of pumps, peristaltic pumps can operate without liquid without risk of damage.

- “Heating shirt": Available for models that work with temperature-sensitive liquids. This allows you to maintain optimal temperature conditions during the transportation of products.

- Low operating costs: Thanks to its simple design and easy hose replacement.

- Resistance to aggressive environments: Suitable for use with acids, alkalis, and chemically active suspensions.

How to choose a peristaltic pump

- Fluid characteristics: Determine the chemical composition, viscosity, solids, and temperature of the liquid.

- Hose material: Choose a material that matches the fluid's properties (chemical resistance, sterility, etc.).

- Productivity: Consider the volume of fluid pumped per unit of time.

- The presence of a “heating jacket”: If your product is temperature sensitive, choose a pump with this feature.

- Operating environment: Ensure that the pump meets the requirements for safe operation in explosive or sterile environments (if applicable).