Their efficient operation, however, depends on periodic maintenance, with the key aspect being the availability of high-quality spare parts for pump equipment,which are now offered at affordable prices. These parts can be ordered with fast delivery across Kyiv and Ukraine, along with certified products backed by warranty and service commitments.

The Importance of Timely Equipment Maintenance

Regular maintenance, diagnostics, and replacement of worn parts help avoid unexpected breakdowns and serious malfunctions in pump operation, which could result in unforeseen expenses and production downtime. Additionally, proper care reduces stress on key mechanisms, ensuring high productivity over an extended period.

Another critical aspect is operational safety. Neglecting proper maintenance can lead to accidents involving damage to system components or even risks to personnel. Timely replacement of worn parts, offering a range of components, we are ready to handle not only their selection but also the prompt delivery across Kyiv and Ukraine. Moreover, we guarantee a full range of accompanying services. All separator parts presented in the catalog are affordably priced and come with mandatory warranties, making the choice in our favor a reasonable and cost-effective solution available, as well as cleaning and performance monitoring, help maintain equipment reliability while minimizing the risk of malfunctions.

Key Components to Consider

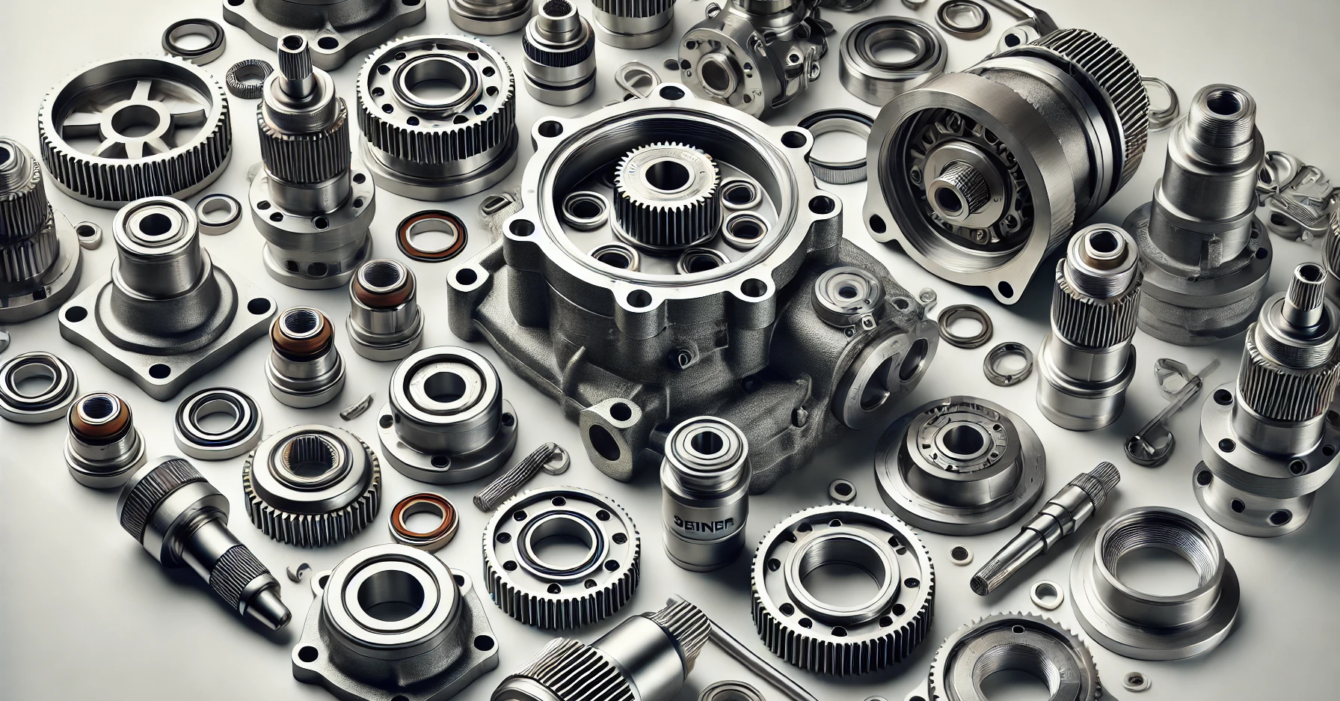

When ordering spare parts for industrial pumps, it’s essential to prioritize the following components:

- Rotors. Responsible for fluid movement and the continuous operation of the system. Rotor wear typically leads to reduced performance.

- Stators. Ensure the stability and immobility of rotating parts, maintaining proper flow direction within the mechanism.

- Membranes. Provide system airtightness, protecting against leaks and maintaining the necessary pressure.

- Balls. An essential component of the valve system, controlling the flow of liquids or gases.

- Mechanical Seals. Ensure the sealing of rotating parts, protecting the equipment from leaks and extending its lifespan.

- Hoses. Used for fluid transport, with durability against wear and environmental exposure being a critical factor for the long-term operation of the system.

What to Consider When Choosing Spare Parts

Before purchasing spare parts for pumps, it is vital to ensure their compatibility with the equipment. It’s important to verify that all components meet the required dimensions, pressure ratings, and operating characteristics of the pump to avoid rapid wear of parts or equipment failure. Another critical consideration is the environment in which the pump will operate, as different materials perform differently under high pressure, extreme temperatures, or when interacting with various liquids.

It is also worth considering the resistance of spare parts to wear and corrosion, especially if the pump is operated in aggressive (difficult) conditions. This will help to ensure the durability of the components, guaranteeing their reliable operation for a long time. Ease of installation and the possibility of quick replacement if necessary should also be considered, as this is what largely determines equipment downtime and its overall performance in solving the tasks at hand.

Selling spare parts for pumps at a favourable price, we take a comprehensive approach to cooperation with each partner. We undertake not only the selection of equipment and its delivery across the country, but also the commissioning of the units with their subsequent maintenance. Including after the warranty period has expired. We are ready to take into account all the wishes voiced by the partner, even in the most difficult and non-standard situations, guaranteeing the desired result.