Система охолодження є критично важливою частиною промислового обладнання. Вона забезпечує стабільний температурний режим, захищає вузли від перегріву та підтримує продуктивність виробничих процесів. Неправильний вибір системи охолодження може призвести до передчасного зносу компонентів, аварійних зупинок і збільшення енергоспоживання, тому інженерний аналіз є обов’язковим етапом.

Основні типи промислового охолодження та їх застосування

1. Водяне охолодження

Один із найефективніших способів відведення тепла. Вода має високу теплоємність, тому здатна швидко переносити значні обсяги тепла.

Advantages:

- висока ефективність теплообміну;

- стабільність температури при великих теплових навантаженнях;

- можливість роботи у замкнутому контурі (чілери, глікольні системи).

Недоліки:

- залежність від доступності води;

- потреба в трубопроводах і насосному обладнанні;

- ризик корозії або обростання без правильного водопідготовлення.

Застосування: харчова промисловість, металургія, екструзія, автоклави, великі гідравлічні системи.

2. Повітряне охолодження

Використовує атмосферне повітря як теплоносій. Найпростіший і найдешевший тип охолодження.

Advantages:

- низька вартість встановлення;

- відсутність води або рідин у контурі;

- мінімальне технічне обслуговування.

Недоліки:

- низька ефективність при високій температурі навколишнього середовища;

- залежність від вентиляції;

- обмежена тепловіддача.

Застосування: компресори, серверні шафи, малопотужне електронне обладнання.

3. Охолодження рідким теплоносієм (оливою, гліколем, спеціальними рідинами)

Розглядається, коли повітря недостатньо, а вода — недоступна або небажана.

Advantages:

- стабільний теплоперенос без залежності від вологості чи температури повітря;

- можливість роботи у герметичних системах;

- висока ефективність і низький ризик корозії.

Недоліки:

- більш складне обслуговування;

- вища вартість;

- необхідність насосної групи.

Застосування: високоточна електроніка, обладнання для харчової промисловості, охолодження гідравлічних станцій, лазерні системи.

4. Термоелектричні системи (елементи Пельтьє)

Підходять для невеликих вузлів або точкового охолодження.

Advantages:

- компактність і точність;

- можливість працювати у складних умовах;

- відсутність рухомих елементів.

Недоліки:

- невисока продуктивність;

- не підходять для обладнання з великим тепловим навантаженням.

Застосування: лабораторні установки, оптика, малі електронні модулі.

Як вибрати оптимальну систему охолодження?

При виборі системи необхідно враховувати:

1. Тип обладнання та теплове навантаження

Кількість тепла, яку потрібно відвести, визначає тип теплоносія та потужність системи.

2. Температурний режим роботи

Якщо потрібна точність ±1°C — потрібні рідинні або чілерні системи.

3. Умови експлуатації

Вологість, температура, запиленість, доступ до води та енергоресурсів.

4. Енергоефективність та вартість експлуатації

Найкраща система — та, яка забезпечує потрібну продуктивність при мінімальних витратах енергії.

5. Екологічність та безпека

Сучасні системи мають працювати без шкідливих викидів і з мінімальним споживанням ресурсів.

Приклади застосування в різних галузях

Food industry

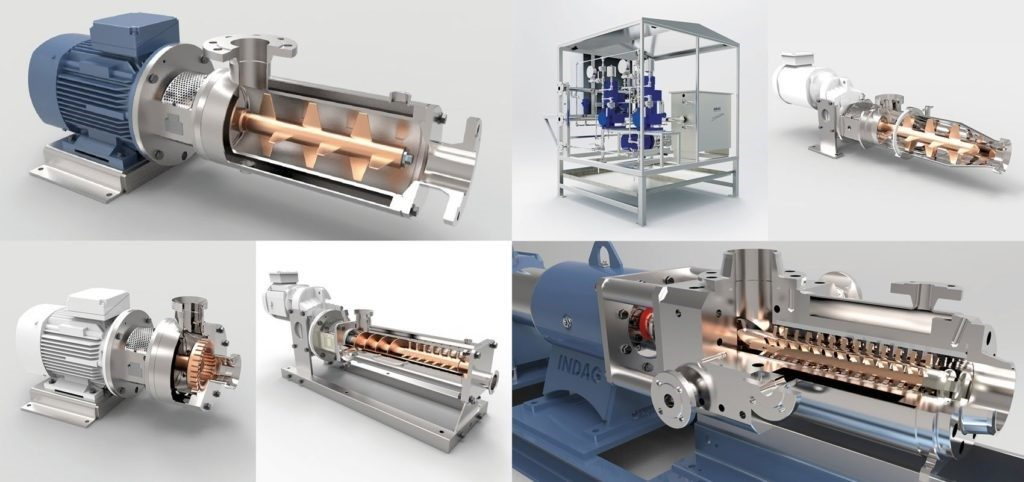

Часто використовують водяні або глікольні системи для охолодження реакторів, змішувачів, теплообмінників, екструдерів. Гліколь безпечний, не контактує з продуктом і забезпечує стабільну температуру.

Електронна промисловість

Рідинні діелектричні охолоджувачі дозволяють відводити тепло від мікрочипів, плат та блоків живлення без ризику коротких замикань.

Металургія та важка промисловість

Водяне охолодження сталей, пресів, гідросистем і печей є обов’язковим для підтримання безпеки та ресурсу обладнання.

Conclusion

Оптимальна система охолодження — це баланс між ефективністю, вартістю, умовами експлуатації та вимогами до точності температури. Грамотний технічний аналіз дає змогу підібрати рішення, яке забезпечить стабільну й безпечну роботу обладнання протягом усього життєвого циклу.