The production of dairy products involves many mixing processes of different nature and intensity, such as blending, dispersing, homogenising, etc.

Who is the expert in mixing processes?

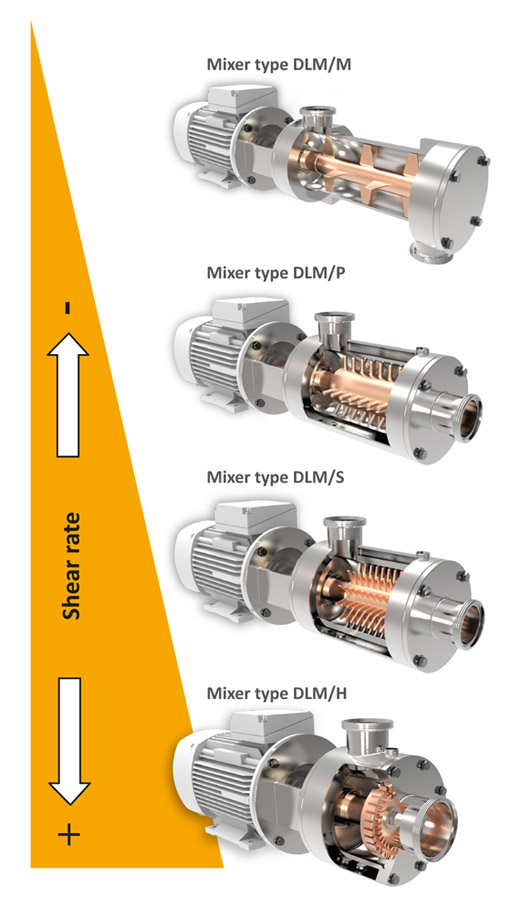

For more than half a century, Indag Maschinenbau GMBH (Germany) has been manufacturing dynamic mixers for a variety of applications and industries. The company was founded in 1953 in Borsfleet, a town in northern Germany near Hamburg. Over the years, Indag has grown into an international player in the mechanical engineering market and today 70% products are exported to more than 65 countries around the world. mixing. The conceptual range (shown in Fig. ) is graded in terms of shear force, i.e. from gentle mixing to intense homogenisation. Depending on the process requirements, a mixer with the appropriate level of shear force is selected.

Application of dynamic mixers in the production of dairy products

One of the most common processes for mixers in the dairy industry is the mixing of yoghurt with fruit filling. This process can be implemented either in batches or by an inline mixing system. The latter option is more progressive and it is for this purpose that the use of a dynamic mixer is relevant. The essence of the process is based on the dosing of all the ingredients of the final product into the line where the dynamic mixer is located. After mixing, the finished product goes into a storage tank or directly into the hopper of a packaging machine. In the first case, mixers with one inlet and one outlet are usually used. In the latter case, mixers with a larger dosing pulsation compensation size are used.

Furthermore, these machines can be equipped with multiple outlets depending on the filling machine configuration. When it comes to simple mixing with a product feed of up to 6 bar, Indag offers the standardised ECO series with the following performance range:

DLM/M-1 ECO max. up to 0.5 - 2 m³/h

DLM/M-2 ECO max. 2 - 5 m³/h

DLM/M-3 ECO up to a maximum of 5 - 13 m³/h

This series is also not available with a heating/cooling jacket and has only one type of mixing element in the form of fins. For more sophisticated mixing processes, the basic DLM/M HY series is used, with the performance values listed below:

DLM/M-2 standard: 0.5 - 1 m³/h (available with 4 outputs as standard)

DLM/M-3 standard: 1 - 2.5 m³/h (available with 4 or 8 outlets as standard)

DLM/M-4: 2.5 - 4m³/h (available with 4 or 8 outputs)

DLM/M-5: 4 - 6m³/h (available with 4 or 8 outputs)

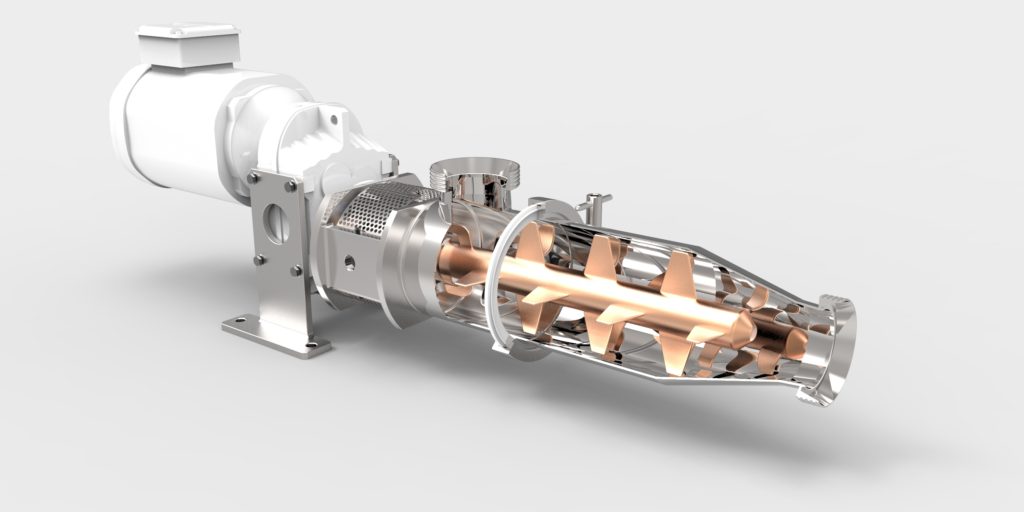

This is the basic range of low-shear dynamic mixers in a hygienic design. They are suitable for mixing dairy products as well as other food applications. The mixers can be equipped with a variety of mixing elements, operate at different speeds and are made in an aseptic design (Fig. ). In other words, the technical solution can be 100% adapted to the needs of the process.

The main advantages of Indag DLM/M series mixers:

- The INDAG ECO series is specially adapted to the requirements of dairy production, offering the best price/performance ratio.

- The low volume of product in the mixing chamber means less waste during cleaning and maintenance.

- Easy replacement of the single shaft seal with a double shaft seal. The mixer design is single and seal-independent.

- Open-type mechanical shaft seal.

- The flow, and therefore the accumulation of harmful microflora, can be easily detected visually.

- Possibility of horizontal or vertical installation.

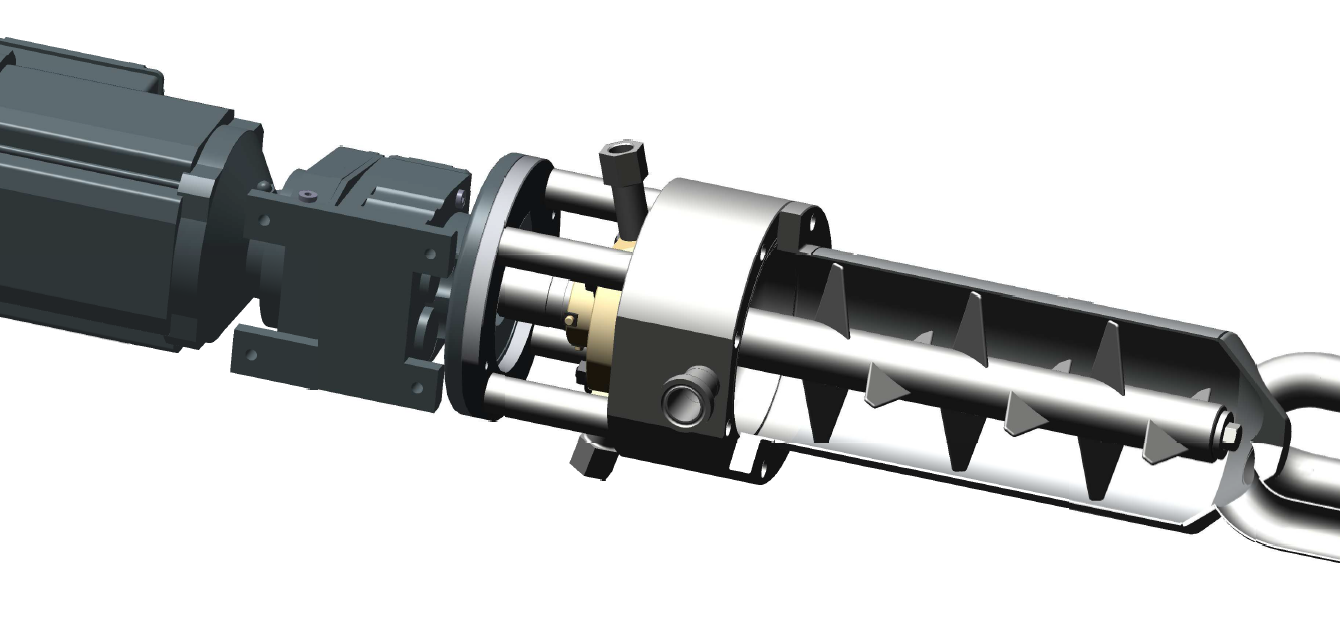

- Various rotor configurations are available, such as blades and hooks (Fig.)

- The rotor can be easily changed without changing the mixer design. Indag is ready to develop a customised mixer design for the 100% to suit the customer's process.

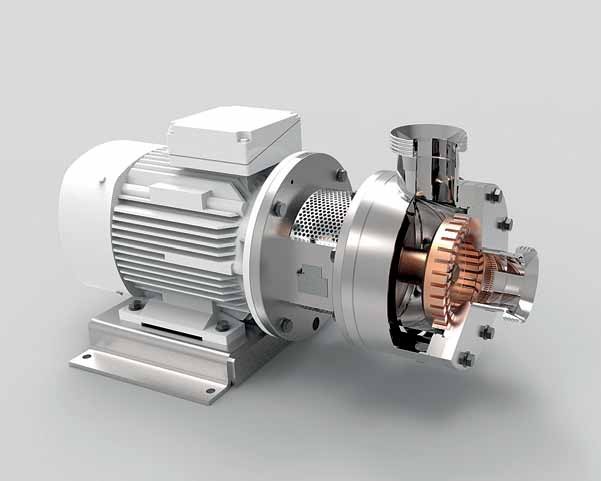

The DLM/H -HY series with high shear forces is also available, which is particularly suitable for the preparation of homogenised dairy products. For example, this could be a dairy dessert consisting of milk, yoghurt and quark. All these ingredients need to be mixed to a homogeneous texture. A high-shear machine, as shown in Fig. The product enters the working chamber, where it is literally ground in the gaps between the rotor and stator. These mixers are also manufactured in accordance with all hygienic requirements - materials, no dead spots, double mechanical shaft seal with flushing, etc. Customised versions are also available, e.g. with more wear-resistant materials for use with abrasive products.

For more information about the equipment, please contact our technical specialists. We will be happy to advise you and provide the best solution.