Today, more and more companies are not only growing fruit and vegetables, but are also actively engaged in their processing. Therefore, it is almost impossible to achieve success without the use of innovative technologies.

M.F.T. srl. is an Italian company that manufactures equipment and offers technologies for processing, processing and extending the shelf life of berries and fruits, and creates devices, machines and complete turnkey projects, technological schemes for fruit and vegetable processing for its customers (both small and large farms). M.F.T. srl. offers machines and complete solutions for the processing of fruits and vegetables, mainly for the production of jams or preserves, nectars, dried fruits, and frozen fruits. In terms of the technological chain of the production cycle, we can provide inspection and sorting of raw materials, peeling, core extraction, pitting, slicing, grinding and mashing, concentration, filling and pasteurisation of the final product. Jam-making equipment includes inspection, sorting fruit from the skin, core extraction, pitting, mashing, mixing various ingredients and cooking, filling, sealing, labelling glass jars for jams made from various fruits and berries. installation of equipment - before training of employees. At the initial stage, we give advice, because the client needs not only equipment, but also support in creating a new product on the market. We share our vision of the project, the client can apply it or have their own opinion, and together we create an innovative product. One of our main principles is not to rest on our laurels. During trainings, M.F.T. srl. teaches how to operate the equipment correctly and what kind of maintenance is required for certain installations.

During the installation and commissioning of the machine, we provide a package of spare parts for the most commonly worn parts, which can last for two years of operation. For example, the knives for removing pith or core are particularly prone to failure. The machine itself can operate for many years without any additional maintenance, but there are some parts that sometimes need to be changed. It is worth emphasising that a lot depends on the correct operation of the machine. Only the knives wear out, but all other parts of the machine (here we mean peeling and pitting machines), if maintained according to our instructions, with timely preventive maintenance and lubrication, can last a very long time, being passed down from generation to generation. M.F.T. SRL specialists provide customers with complete solutions for the processing of raw materials.

Based on our experience, we see that it is very important to have a good understanding of the technical task together with the client from the very beginning. Very often we come across the fact that clients do not know how to start or plan their production process correctly, and in such cases we are involved from the moment the correct technical task is formulated in order to enter the market with the product that is in demand and meets all the parameters of a quality product, optimising all production cycles.

AUTOMATIC CORE SLICER WITH AUTOMATIC FEEDER FOR APPLES MODEL MW-R

This machine has been designed to core apples and cut them into slices (rings), making it ideal for processing apples for the production of apple crisps or for further use in the confectionery industry, for the production of fresh fruit salads or for the production of fruit snacks. It can also be used simply to core apples.

This machine is made entirely of AISI 304 stainless steel and can be integrated in lines with other machines to automatically feed through the loading area where the fruit enters. The product is then sent through the elevator to the conveyor, with an automatic orientation system that allows the fruit to be automatically aligned into its cells. Apple cutting is fast and precise, without affecting the organoleptic properties, and guarantees maximum hygiene. Here, the core is cut out of the apples and they are sliced into slices using interchangeable cutting blocks that allow for different diameters and thicknesses. The slice thickness is adjustable, with a minimum thickness of 2 mm. The slices are discharged via a belt that can be extended as required to connect to the next machine. The waste falls down, where a collection box can be placed or, if ordered, a conveyor belt can be supplied to divert it to the desired destination. All protective sumps are locked with a movable hinge and allow for quick opening, thus optimising time for normal operation and maintenance. This allows for easy, quick and safe maintenance of the machine as well as thorough cleaning.

MACHINES FOR PEELING AND CORING FRUIT - MM SERIES

The MM series fruit peelers are suitable for mechanical peeling with knives and can be used for the following fruits: apples, pears, kiwi, oranges, grapefruit, lemons, peaches, nectarines, persimmons, prickly pears, bergamot. It can also be used to peel some vegetables, such as aubergines, zucchini, and yucca. According to its layout, the machine can perform the following operations: peeling, coring (straight or with core removal), halving, segmenting, cutting into slices (not thinner than 10 mm).

The special patented knife peeling system has several advantages: The fruit is not crushed, instead it is gently peeled by removing the long ribbon of skin, which, for example for the production of limoncello zest, allows perfect separation from the top layer without destroying the fine cells containing essential oils.

It also allows the processing area to be kept very clean, an important aspect for the food industry.

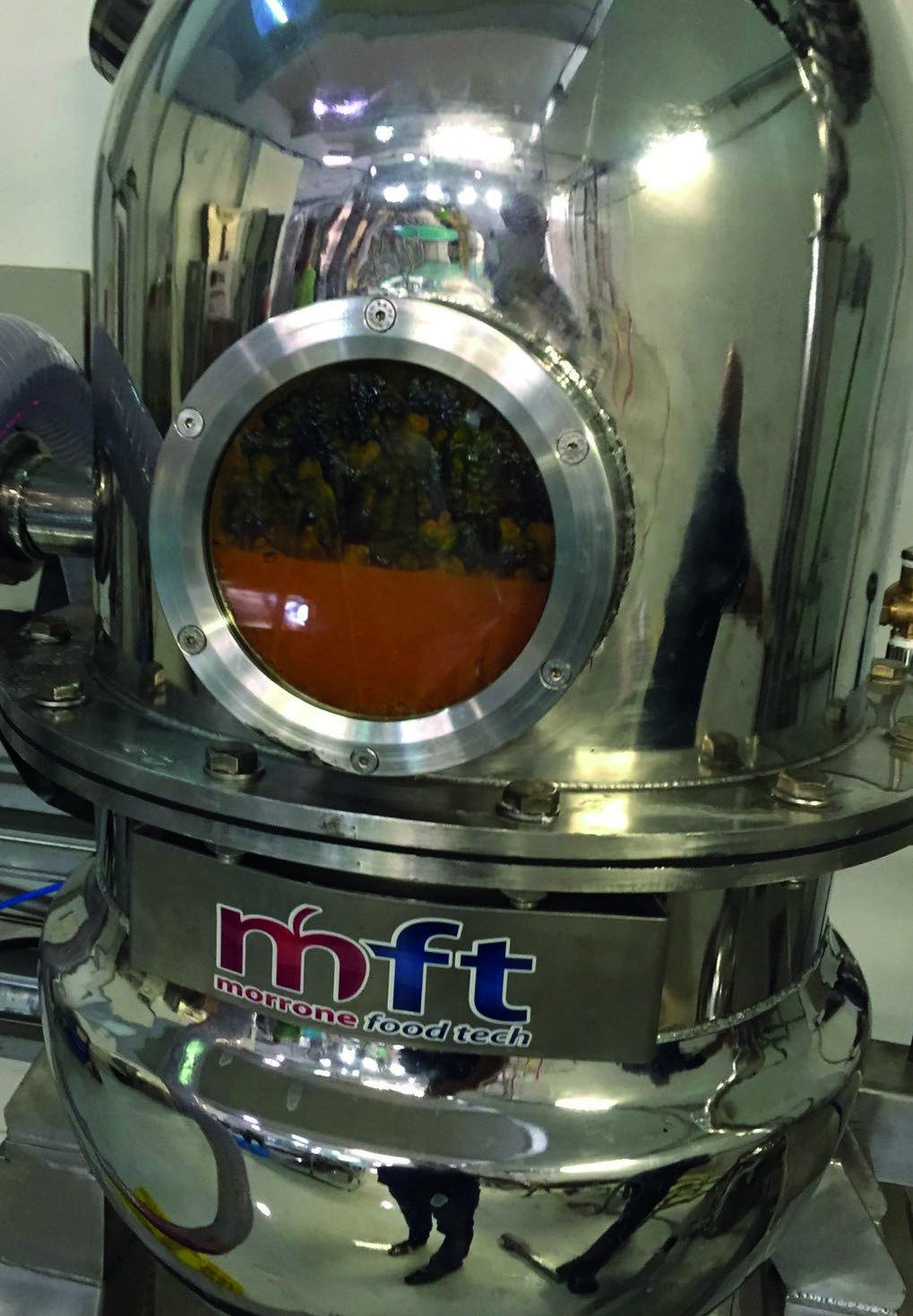

MULTIFUNCTIONAL UNIT WITH VACUUM BOILER COMPLETE WITH DOSING AND CAPPING MODEL K–FC45

This unit is designed for the production of tomato paste (passata, sauces), jam, preserves or salsa filled into jars of various sizes.

This unit is designed for the production of tomato paste (passata, sauces), jam, preserves or salsa filled into jars of various sizes.

Vacuum boiler with a diameter of Ø 400 mm, operated by steam with a maximum operating pressure of 3 bar

DOSER / Pneumatic filler has an adjustable dosing capacity from 10 cc to 1100 cc. All parts in contact with the product are made of AISI 314 stainless steel.

The machine is equipped with a manual feeder for glass jars and lids, with one type of lid (twist-off).

Everything works in a closed cycle. First, the raw material (fruit for jam production) is prepared, cooked in a small vacuum boiler, then we move on to the dosing machine, and the operator simply presses a button to dispense his product. Then comes the capping process, which is carried out immediately after dosing.

One person can handle this unit perfectly. 45 litres of raw materials can be collected in the cooking pot and processed in one cycle. I should note that this equipment is in demand because some companies buy this unit to test a new product, while others use it as a starting production cycle for their product. There are similar offers for chips. For example, we have a machine that automatically receives apples and processes them, i.e. there is a hopper for receiving raw materials, then an elevator that lifts each apple and orientates it for further processing, removes the core and immediately cuts it into slices. And it's a single unit, so there's no need to buy separate machines for core extraction and cutting.

What is the secret of this machine? It perfectly orients the apple to maximise product yield, so there is almost no waste. The only thing is that if the customer wants to make peelless chips, then other equipment is used for this function and a separate peeling machine must be added to the production process. Our customer always has a choice. "- will definitely punish us with their availability, ease and healthy snacking.

Benefits of fruit snacks:

- You can always take it with you in your bag or backpack.

- That's why you won't be caught off guard by hunger.

- Full of vitamins and nutrients.

- The benefits of eating them are the same as those of fresh fruit.

- They give a boost of vigour and strength. Eating these products for breakfast has a very beneficial effect on the general well-being of a person.

- They allow you to keep fit because they contain a minimum of calories.

- Eating fruit snacks is a unique opportunity to make snacking on the run as healthy as possible. They quickly give you a feeling of satiety, which is especially important for those on a diet.

- Fruit snacks are very convenient to eat.

- They are thinly sliced pieces of berries or fruit that can be easily removed from the packaging without getting your hands dirty.

- Plus, they have a long shelf life, so they can be stocked up for good.

M.F.T. srl have developed different production cycles for their customers to enable them to start with a mini workshop to test the market or to go straight to large batches of finished product.