Pâté is a homogeneous, finely minced mixture of meat, vegetables, mushrooms or other ingredients. This product is quite popular in our daily diet; it is delicious, nutritious and healthy. In addition, the variety of possible ingredients allows you to create the most interesting recipes.

In our article, we will talk about a group of sterilised pâtés that are most often found on the shelves of Ukrainian supermarkets. Sterilised products are very popular primarily because of their long shelf life. An alternative option is chilled products, which must be stored in a refrigerator at +4 – +6°C. First, let's figure out what sterilisation is and why it is needed.

The term ‘sterilisation’ refers to the process of heat treatment to destroy harmful microflora such as microorganisms, bacteria, fungi, etc. We all know how long fresh or even cooked meat can be stored – a maximum of 3-4 days. The shelf life of sterilised canned meat is several years.

Freshly prepared pâté is not only a delicious addition to toast with butter, but also a potential breeding ground for harmful microorganisms. After a certain period of time has elapsed since preparation, our dish becomes unfit for consumption and, moreover, dangerous to human health. The solution that prevents product spoilage is heat treatment, i.e. sterilisation.

During sterilisation, the product is kept in a hermetically sealed container. For example, pates can be seen in a tin can, glass or laminate tray. Being in a closed container, after sterilisation, the product remains isolated and inaccessible to foreign microflora.

Heat treatment modes are selected based on the characteristics and properties of the product. In particular, the main factors are the ratio of water to dry matter, acidity and sugar content. The size of the container in which the product is stored should also be noted. The temperature must penetrate each layer of the product; the thicker the layer, the more difficult it is. For example, heating two identical cans of pâté and water will require different amounts of heat, as thermal conductivity depends on viscosity. The more viscous and dense the product, the more difficult it is for molecules to move and transfer heat energy.

The sterility of a canned product can be achieved by maintaining it at a temperature above 100 °C for a certain period of time. The sterilisation cycle is always defined in terms of a temperature/time pair. Exposing the product to temperatures above 100 °C for a certain time leads to the accumulation of a sterilising value, called the Fo value (F zero). The appropriate time/temperature or Fo value required for a given product depends on the population (number), nature of the microorganisms or degree of contamination. The higher the number, the higher the Fo value and vice versa. To determine the sterilisation cycles, each new product is subjected to heat penetration tests. These tests help to determine at which combination of time and temperature the required Fo value is achieved to ensure sterility. This appropriate amount can be achieved either by a high temperature and a short time or by a lower temperature and a longer time. Any combination of time and temperature can achieve the desired result. However, the quality of the products after sterilisation may vary depending on the combination chosen. The following are examples of temperature and time combinations for a Fo number of 10:

– 41 minutes at 115°C

– 10 minutes at 121°C

– 3.2 minutes at 126°C

– 1.3 minutes at 130°C

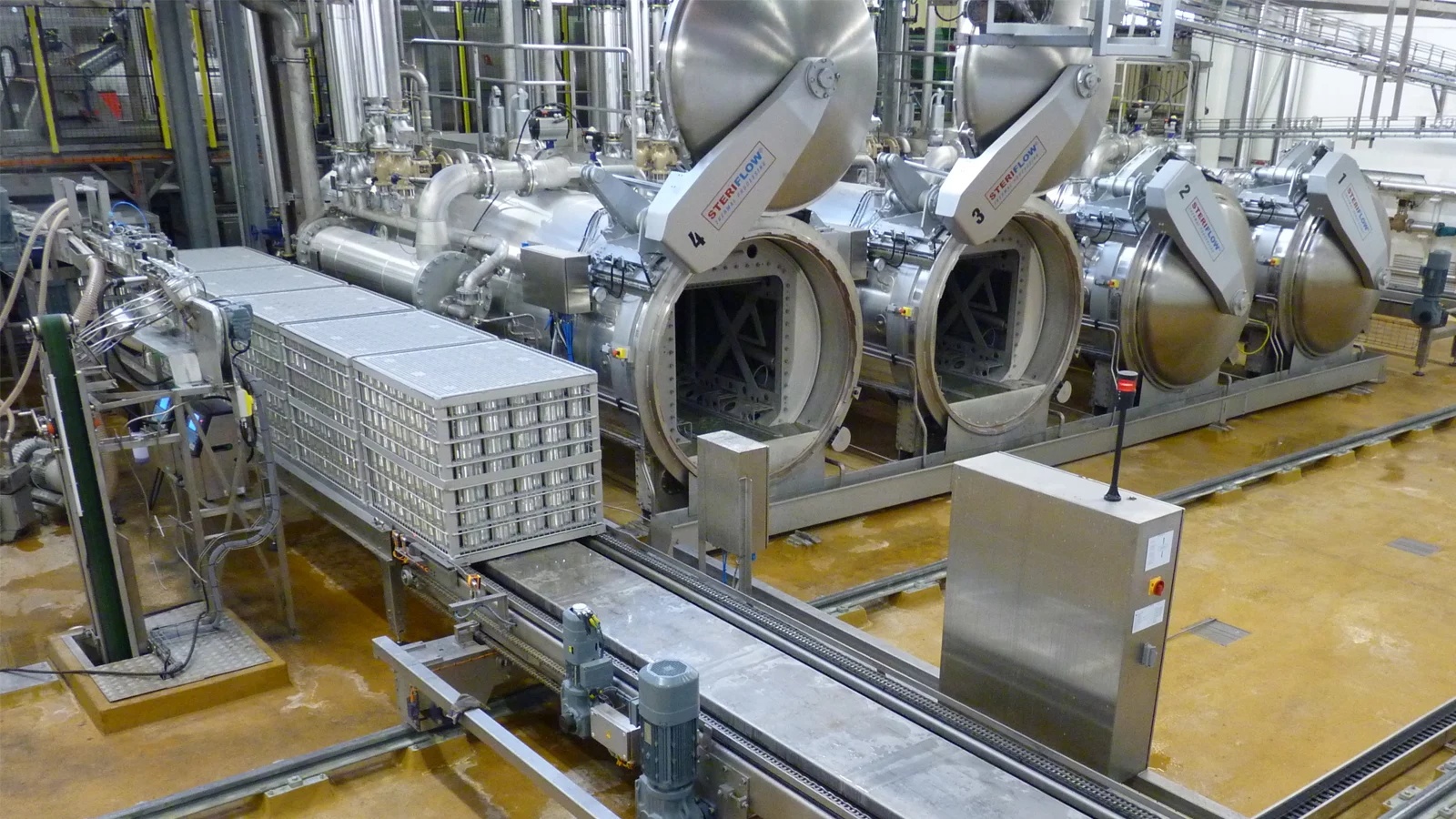

On an industrial scale, sterilisation is carried out in production enterprises using devices called autoclaves. An autoclave is usually a cylindrical (horizontal or vertical) pressure vessel. The packaged product is loaded into it and heated. There are various heating technologies – complete immersion in water, treatment with superheated steam, spray. But one of the most versatile and advanced solutions is the ‘water cascade’ technology developed by Steriflow in the 1970s. For over 40 years, Steriflow solutions have been associated with reliability and energy efficiency. One of the most versatile and advanced solutions is the ‘water cascade’ technology developed by the French company

Overall, there is nothing supernatural about the design of Steriflow: the autoclave consists of a cylindrical vessel, a pump, a valve rack, a control panel and a plate heat exchanger. Modern mechanical engineering knows much more complex designs. But here the expression ‘all genius is simple’ is appropriate. In addition, the highlight of Sterilfow's creation is the Platular all-welded plate heat exchanger. The fact is that Steriflow is part of the Barriquand group of companies, global specialists in non-standard heat exchange equipment. First of all, it should be said that the heat exchanger determines the principle of the water cascade. Inside the autoclave, there is a constant volume of water that circulates through the heat exchanger and irrigates the product inside the vessel. During heating, superheated steam is supplied to the outer circuit of the heat exchanger, and during cooling, cold water is supplied. The task was to develop a heat exchanger that was as adapted as possible to the production modes of sterilisation. A critical issue is resistance to thermal expansion of the metal, which occurs when switching abruptly from steam to cold water. Throughput capacity is also an important consideration. Platular embodies the solution to all these issues.

Two things are important in the production of canned pâtés: the quality of sterilisation of the final product and energy efficiency. With the Steriflow autoclave in your arsenal, you get the gentlest and most effective heat penetration into the product. As a result, you get a shorter sterilisation cycle and no burning of the product. – Uniform temperature distribution, resulting in consistent quality throughout the entire batch at the end of the cycle. – Low energy consumption, namely steam and water.

The heat exchanger allows the recycled warm condensate and water to be recirculated. Independent control of back pressure and water irrigation allows products to be processed in all possible types of packaging, whether soft or rigid.

All of the above makes the Steriflow autoclave the ideal sterilisation tool and an excellent solution for sterilising pâtés.

The topic of autoclaves is quite in-depth, and if you have any questions, you can talk to the specialists of Steiner-Ukraine, the exclusive representative of Steriflow in Ukraine, for more information.