Today, cosmetics are available in a wide range on the modern market. They are used by a large number of people because they improve their health and self-esteem. Manufacturers of such products satisfy people's desire for beauty and cleanliness. Therefore, they must use high-quality cosmetics production equipment so that you can achieve outstanding results. Mixing equipment provides the necessary resources to produce high-quality and safe products. Models from well-known brands combine precision and high performance. Thanks to reliable technology, the products will be of the highest quality.

Scope of application of faucets in the cosmetics industry

It is impossible to imagine the production of modern cosmetics without such a system. They are used wherever uniform mixing of bulk materials is required. The equipment allows for the production of the following product groups:

- Hygienic. This includes dry shampoo, baby powder, talcum powder, etc.

- Blush, foundation, eyeshadow.

- Special mixtures for the production of various types of decorative cosmetics, such as mascara and lipstick.

- The basis of skin care. This category includes a variety of face masks, lotions and creams.

Innovative production of cosmetics

There are many types of cosmetics with unique production characteristics. Eyeshadows, blushes, loose powder and other products must meet certain standards:

- Easy to use.

- Benefits for the skin.

- Sustainability.

- Pleasant smell and visual appearance.

All this plays a vital role for consumers. Therefore, innovative equipment is used in production. Mixers and reactors for the cosmetics industry meet all the requirements and standards. High-quality mixing is guaranteed thanks to the availability of many processing functions. The result is high-quality products for hygiene, body care, personal care, etc.

Specialised reactors for the production of cosmetics have many advantages. They help to make mass production efficient. The main features of the equipment from well-known brands include the following:

- Fine homogenisation, dispersion, agglomeration and other types of processing.

- The flexibility of the fill level is variable. The filling can vary in different ranges from 10% to 100%.

- Capable of handling sensitive and valuable ingredients.

- Cleaning is quick and easy.

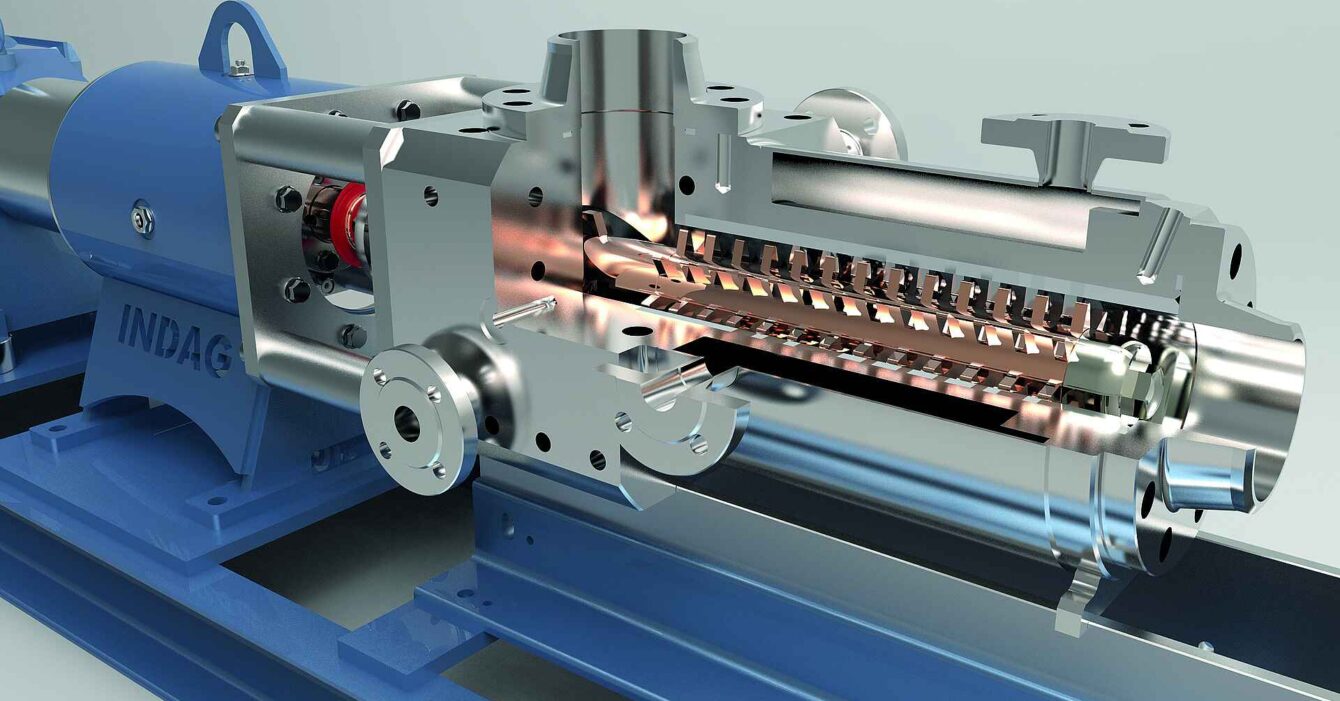

Modern mixers from the German manufacturer INDAG are ideally suited to the needs of the cosmetics industry. The best model can be selected for the specific needs of the business, performing its direct function reliably and efficiently. All this will affect the realisation of the main mission of the enterprise.

INDAG is a German manufacturer of mixers for high-performance mixing, dispersing, homogenising and emulsifying.

INDAG manufactures dynamic mixers for all industries including food, chemical, pharmaceutical and environmental. If you are looking for a mixer with hygienic handling and a gentle mixing process, Steiner has the solution for your product.

For more information about this equipment, please contact our technical specialists by phone:

+38(044) 390 73 38. We will be happy to advise you and provide the best solution.