Carbon dioxide stunning, blood collection and processing

Every year, the requirements for product quality are increasing, which is directly related to the production processes and its overall condition. First and foremost, compliance with sanitary and hygienic standards on the farm and competent waste management, which, instead of incurring additional costs, should be profitable, as is the case with the Danish company Butina.

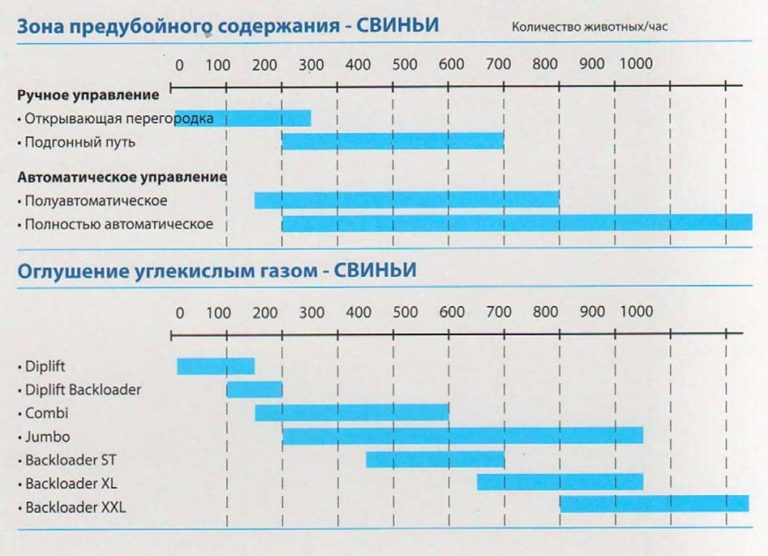

Butina was founded in 1972. It is currently the world leader in the production of carbon dioxide stunning equipment and automatic feeding lines with a capacity of up to 1500 pigs per hour. Animal handling and stunning is a specialised niche that requires an understanding of animal behaviour and knowledge of the entire production process, which directly affects the quality of meat. Close cooperation with customers, leading suppliers and research institutes has enabled Butina to take a dominant position in this area. Butina offers a wide range of equipment, group stunning systems with a capacity of 100 to 1500 pigs per hour, including automated feeding tracks.

Products and performance

The main advantage of group stunning with carbon dioxide is the humane treatment of animals. The process is designed to take into account the natural curiosity of animals:

- less noise;

- less stress for animals;

- better working conditions.

The Diplift and Combi systems are successfully used all over the world in facilities with capacities ranging from 40 to 200 pigs/h. These small carbon dioxide stunning units are available in galvanised or stainless steel. They are easy to handle and maintain.

Equipment Diplift is designed for a capacity of up to 120 pigs per hour. It avoids blood leakage and reduces weight loss.

System Jumbo is semi-automatic. Animals are escorted to the stunning zone in groups and placed in a box by two.

System Backloader is used in enterprises that, regardless of productivity, want to use modern technologies in the field of carbon dioxide stunning, focusing on humane treatment of animals and product quality.

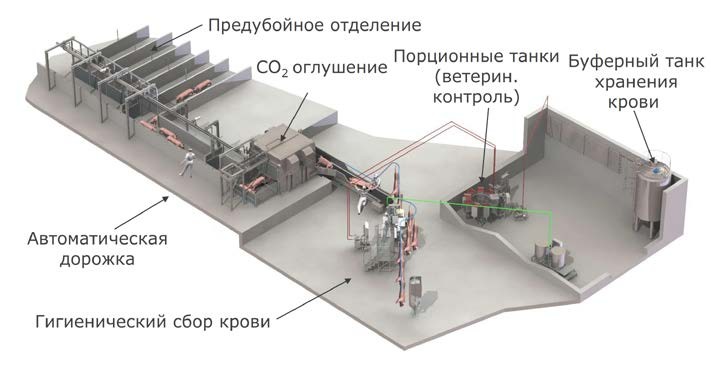

Before entering the stunning box, the animals are divided into small groups and then enter an automatic box, which is lowered into a CO2 environment using an elevator. Blood is collected and processed using a RotaStick device.

Blood collection and processing

The stabbing is performed using the patented Anitec Hollow Knife device, which is an integral part of RotaStic. Vertical and horizontal exsanguination is possible with this system.

The system will require 1-2 operators to operate, depending on the capacity model of the slaughterhouse. RotaStic allows for the simultaneous collection of blood from 10 animals. Each knife is washed and sterilised for further use. Product yield depends on several factors, but in general, about 85% of blood can be collected.

The collected blood is stored in batches with the ability to track each batch at the post-slaughter inspection stage. "Approved" blood is cooled and pumped into a storage tank.

Benefits of food blood collection:

- Blood is a resource, not a problem;

- short payback period;

- plasma can replace raw meat;

- does not contain soy / GMOs.

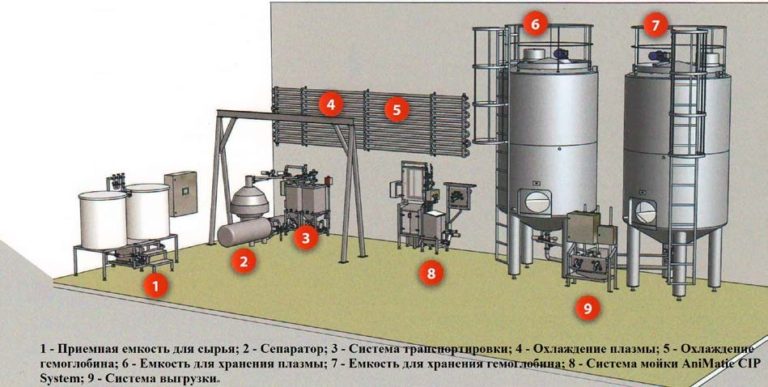

Butina also offers equipment for intermediate storage, drying/freezing of collected blood, and separation of blood into plasma and haemoglobin.

Advantages of plasma:

- does not contain any residual chemicals;

- does not contain GMOs;

- does not cause allergies;

- has a high protein content;

- retains moisture better;

- increases profits.

The equipment fully complies with sanitary and hygienic requirements in accordance with American and European standards. Qualified staff guarantees customers fast and professional technical support services and the supply of spare parts for the equipment offered.