SCANEMUL 175

The scanEmul 175 emulsifier from scansteel foodtech is an emulsifier for production capacities from 2000 to 7000 kg/h. The scanEmul 175 is available in 3 (three) different versions and is equipped with electric motors: 55 kW, 75 kW or 90 kW. As a standard, the scanEmul 175 is available in two versions: with pumped product loading or with a loading hopper. The second variant is equipped with an autonomous feed hopper with one or two augers to avoid pre-mixed product pieces sticking together in lumps.

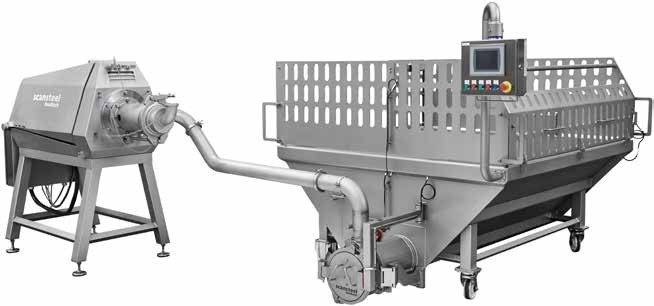

EMULSIFIER QUADROCUT 225 / PENTACUT 225

On a global scale, the QuadroCut 225 / PentaCut 225 emulsifier from scansteel foodtech has won universal recognition as the workhorse of all emulsifiers on the world market. It is one of the best examples of Danish quality equipment designed, engineered and manufactured in Denmark. The QuadroCut 225 / PentaCut 225 emulsifier is a very reliable, highly efficient and stable machine designed to produce a product with the highest degree of homogeneity. The QuadroCut 225 / PentaCut 225 is extremely efficient for the production of pigskin emulsion. In addition to this, the machine's functionality and practicality ensure low production costs as well as a high level of safety and ease of operation.

HEAVY-DUTY CONSTRUCTION FROM THE VERY BEGINNING!

The QuadroCut 225 / PentaCut 225 emulsifier has been designed to withstand the toughest applications. The powerful, heavy-duty frame can easily withstand motors from 90 to 200 kW. The frame and guard are made of AISI 304 stainless steel.

Ultra-flexible assembly of the knife set

The scansteel foodtech knife set cassettes are specially designed so that trained technicians can assemble them right in their own shop. Therefore, the only thing the machine operators have to do is change the knife cassette at the prescribed intervals.

Knife set combinations:

• PentaCut 225: 5 knives - 4 hole grids

• QuadroCut 225: 4 knives - 3 hole grids

• TrippleCut 225: 3 knives - 2 hole grids

• DoubleCut 225: 2 knives - 1 grid with holes