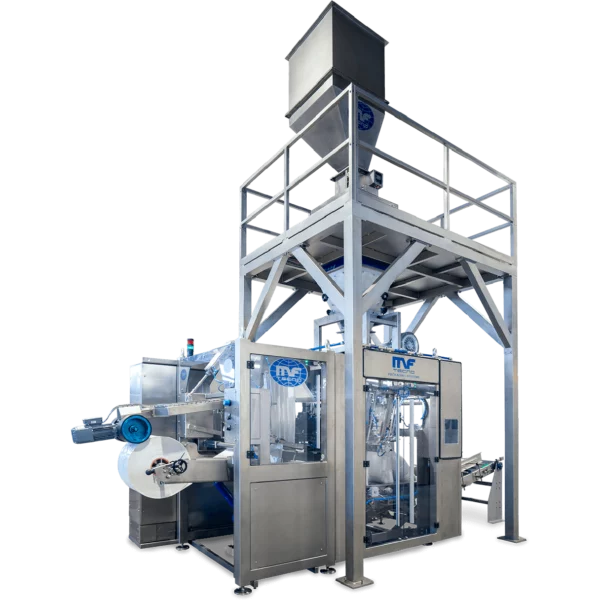

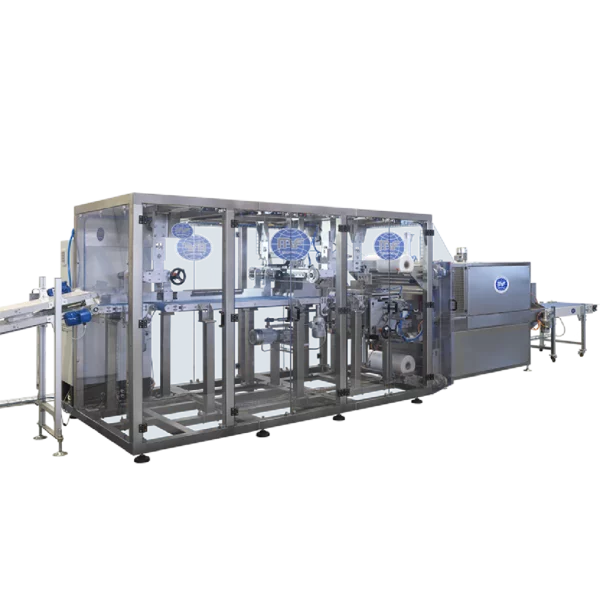

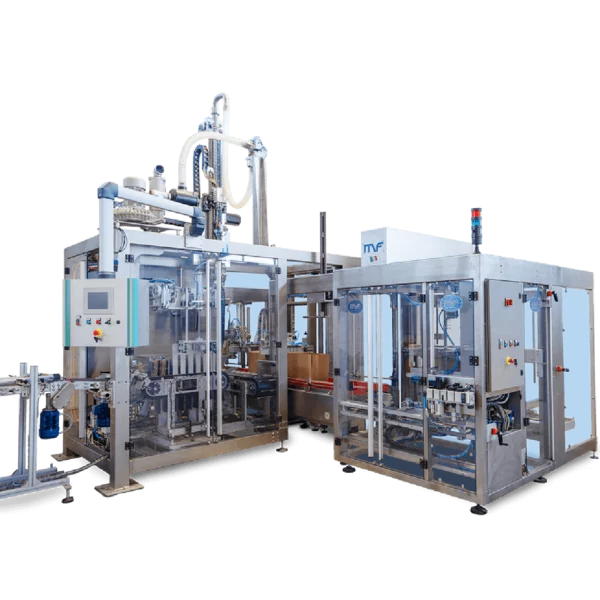

MF TECNO – Feeders for weighing machines

MF TECNO weighing machine feeders are high-precision dosing systems that provide an even flow of bulk materials for accurate weighing. They are ideal for integration with automatic packaging lines to ensure efficient filling of bags and containers.

Gravity dosing system

The MF TECNO gravity dosing system is an effective solution for precise weighing of bulk materials that flow well. It uses gravity to feed the product, providing high speed and accuracy.

Main advantages:

- Minimal mechanical intervention - reduced wear and tear on parts

- High accuracy due to precise flow control

- Suitable for materials with good flowability

Technical characteristics:

- Adjustable gate system for flow control

- High performance with low energy consumption

- Compatible with automatic packaging machines

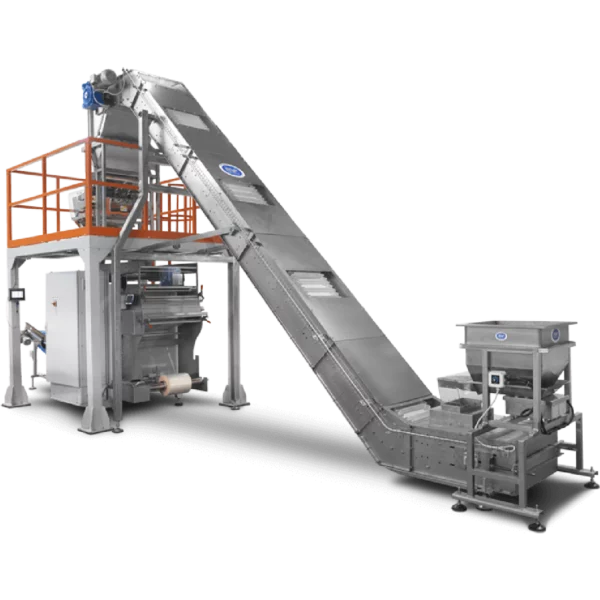

Belt dosing system

The MF TECNO belt dosing system ensures an even product flow for accurate weighing. It is ideal for medium to low flowing bulk materials.

Main advantages:

- Uniform product flow without sticking

- Adjustable feed speed

- Ability to work with various bulk materials

Technical characteristics:

- Using a belt conveyor for dosing

- Speed control for optimum precision

- High reliability in industrial environments

Horizontal screw feeder

The MF TECNO horizontal screw feeder is used for precise dosing of bulk and powdered materials. The horizontal arrangement ensures uniform feeding without spraying or compaction of the product.

Main advantages:

- High feeding accuracy

- Minimal damage to granules and bulk materials

- Ideal for hard-to-flow products

Technical characteristics:

- Made of stainless steel

- Adjustable feed speed

- Possibility of integration with weighing systems

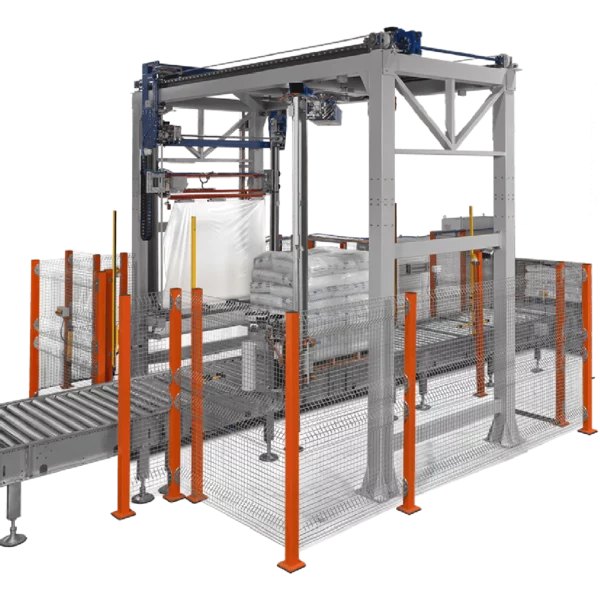

Vibrating dosing system

The MF TECNO Vibratory Dosing System ensures even and precise feeding of bulk materials using a vibrating chute. It is ideal for materials with medium to high flowability.

Main advantages:

- High precision and uniform flow

- No mechanical friction - reduced wear of parts

- Ability to work with fragile materials

Technical characteristics:

- Adjustable vibration intensity

- Stainless steel construction

- Compatible with weighing and packaging machines

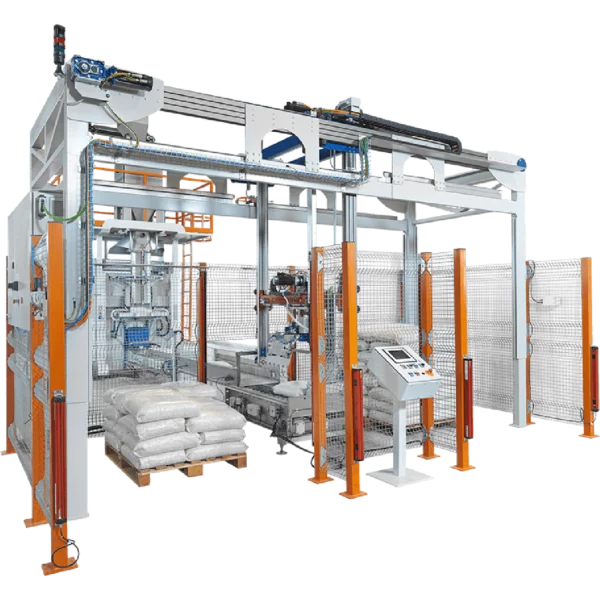

Volumetric belt dosing system

The MF TECNO volumetric belt dosing system ensures uniform product flow by dosing by volume. It is used for bulk materials with low to medium flowability.

Main advantages:

- Constant and controlled material flow

- High performance with low energy consumption

- Easy setup and maintenance

Technical characteristics:

- Using a belt conveyor for precise dosing

- High adaptability for different types of products

- The optimal solution for medium dosing accuracy

Volumetric dosing system with measuring cups

The MF TECNO volumetric dosing system with measuring cups is designed for precise dosing of products in a fixed volume. It is ideal for bulk and granular materials.

Main advantages:

- High dosing speed

- Simple design and easy setup

- Constant dosing volume

Technical characteristics:

- Use measuring cups for precise dosing

- Adjusting the volume of cups to meet production needs

- Reliability and ease of maintenance

Volumetric dosing system with vertical auger

The MF TECNO volumetric dosing system with vertical screw ensures precise dosing of powdered and granular materials. It is used for materials with low flowability or prone to caking.

Main advantages:

- High dosing accuracy

- Ability to work with difficult-to-flow materials

- Minimal dust generation

Technical characteristics:

- Vertical auger mechanism for uniform feeding

- Made of stainless steel

- Ability to adjust the feed speed